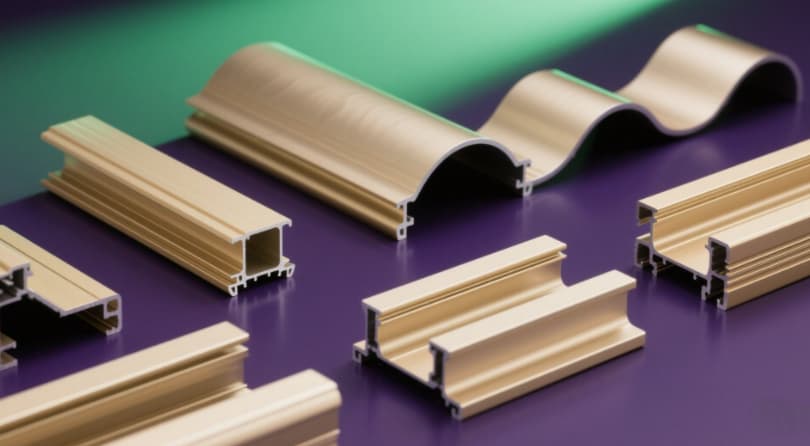

High-quality aluminium CNC machining for precise, durable custom components, ideal for builders, contractors, and distributors worldwide.

Material & Temper :

Custom Aluminum Alloy with Tempering ProcessLength :

By Custom LengthApplication :

Automotive, Electronics Industry, Construction IndustryLead time :

10 to 30 daysExecutable Quality Standard :

GB5237, TS16949, EN12020, EN755, EN573, Or according to customer agreement standardsSurface Treatment :

Anodizing/Powder Coating/Brushing/PaintingColor :

Silver, Champagne, Brown, Bronze, Black, GoldenPackaging method :

Customized according to customer requirementsIn modern manufacturing, the demand for high-precision aluminium components continues to rise. Sunmay offers aluminium CNC machining services using premium aluminium alloys, ensuring each part meets industry-leading standards for strength, toughness, and corrosion resistance. Our advanced CNC equipment supports multi-axis operations, achieving precise cutting and smooth surfaces, meeting customers' requirements for reliability and high accuracy. With our custom aluminium parts solutions, we can manufacture parts according to CAD drawings or samples, while optimizing designs to reduce material waste and improve production efficiency. This flexible manufacturing capability makes our products suitable not only for construction and engineering projects but also for machinery, electronics, and transportation industries. Additionally, our surface finishing techniques, including anodizing, sandblasting, and precision polishing, ensure that components maintain both aesthetic appeal and durability. For projects requiring corrosion resistance or decorative finishes, we offer customized colors and surface effects, guaranteeing long-lasting performance.

| Feature | Advantage | Customer Value |

|---|---|---|

| High-Precision CNC | ±0.01mm accuracy for complex parts | Ensures interchangeability and assembly precision, reducing rework |

| Premium Aluminium Alloy | High strength, corrosion-resistant, lightweight | Extends product lifespan and lowers maintenance costs |

| Flexible Customization | Manufacturing based on drawings or samples | Meets individual project requirements and shortens lead time |

| Multiple Surface Finishes | Anodizing, sandblasting, polishing | Enhances appearance and durability for various applications |

| Fast Delivery | Efficient production and management systems | Reduces supply chain cycles and improves project timelines |

Our precision CNC service goes beyond simple machining. We provide integrated solutions from design optimization and material selection to surface finishing. Understanding customers’ demands for quality, cost, and lead time, we deliver stable, reliable services whether for large-scale production or small-batch custom parts.

| Pain Point | Sunmay Solution |

|---|---|

| Inconsistent part precision | Multi-axis CNC and precision measurement tools ensure consistent accuracy |

| Long customization lead time | Optimized production plans and rapid response mechanisms for fast delivery |

| Difficulty selecting materials | Expert aluminium alloy recommendations balancing strength, corrosion resistance, and machinability |

| Poor surface finish | Mature finishing techniques ensure appearance and performance meet project requirements |

| Cost management challenges | Optimized processing and material use reduce overall manufacturing cost |

Sunmay deeply understands the technical and supply chain challenges customers face in custom aluminium parts production. With our professional support, we provide complete solutions from design to delivery, ensuring each part meets both technical standards and cost-effectiveness. Customers can rely on stable quality and timely delivery, even for highly complex projects.

Construction & Engineering: Aluminium components are widely used in doors, window frames, brackets, and decorative elements. Our aluminium CNC machining ensures strong, precise parts that support structural stability and safety.

Machinery Manufacturing: Components like gear brackets, connectors, and housings require precision. Our precision CNC service delivers complex geometries with consistent tolerances, enhancing machinery performance.

Electronics & Communication: Custom parts are used in device housings and heat sinks. Precision machining and finishing improve both performance and aesthetics.

Transportation: Vehicles, ships, and rail systems demand lightweight, high-strength components. Our custom aluminium parts meet these rigorous standards for structural reliability and durability.

Industrial Automation: Automated production equipment and robots require highly accurate components. Sunmay provides tailored aluminium parts that enhance machine stability and production efficiency.

Sunmay offers comprehensive project delivery and international export capabilities. We employ strict production planning and quality control to ensure every custom aluminium parts order is delivered on time. Through strategic partnerships with global logistics providers, we handle sea, air, and multimodal transportation safely and efficiently, serving markets in South America, Europe, Africa, and North America. Our end-to-end service, from production tracking to secure shipping, provides customers with transparency and reliability throughout the supply chain.

Buyers often focus on part precision, lead time, and cost control when choosing precision CNC service. Sunmay addresses these concerns with optimized processes, high-precision equipment, and flexible customization. We assist in design optimization, material selection, and process planning to ensure each custom aluminium parts meets real-world requirements while controlling costs and supply risks.

Sunmay is a professional aluminium component manufacturer with advanced CNC machining centers, precision measuring tools, and multiple surface finishing systems. Our experienced engineering and technical teams strictly enforce quality control from raw material inspection to final product testing. Certified by international quality standards, our aluminium CNC machining products consistently meet global customer expectations. By emphasizing innovation and equipment upgrades, Sunmay delivers efficient, precise, and reliable services for long-term partnerships.

Sunmay provides end-to-end customization, from design consultation and material selection to process optimization and final delivery. Our custom aluminium parts can be manufactured from CAD drawings, samples, or functional requirements. With rapid response and efficient communication, customers can receive prototypes quickly and proceed to mass production seamlessly. Projects across construction, machinery, electronics, and transportation industries demonstrate our ability to handle highly precise and complex components successfully.

In OEM/ODM partnerships, Sunmay offers a complete workflow: requirement confirmation, design optimization, prototype production, mass machining, quality inspection and packaging, and logistics delivery. Each stage emphasizes efficient communication, professional technical support, and strict quality assurance, ensuring customers receive reliable and stable service throughout the collaboration.

Q1: What types of aluminium CNC machining do you provide?

A1: We offer multi-axis CNC milling, turning, drilling, and engraving services suitable for construction, machinery, electronics, and transportation applications.

Q2: Can you manufacture parts based on my drawings?

A2: Yes, we provide precision CNC service using CAD drawings, samples, or functional requirements, along with design optimization recommendations to ensure parts meet specifications.

Q3: How do you ensure part accuracy?

A3: Advanced multi-axis CNC equipment and precision measurement tools, combined with strict QC, maintain tolerances within ±0.01mm for consistent high-precision results.

Q4: What surface finishing options are available?

A4: Anodizing, sandblasting, precision polishing, and custom color treatments improve corrosion resistance, aesthetics, and durability for different applications.

Q5: What is the production lead time for bulk orders?

A5: Depending on complexity and quantity, lead time from prototype approval to bulk production typically ranges from 2–6 weeks. Optimized workflows allow faster turnaround for urgent projects.

Q6: How is international logistics handled safely?

A6: Partnering with global logistics providers, we manage sea, air, and multimodal shipping with strict packaging and handling controls to ensure custom aluminium parts arrive safely.

Q7: Do you support long-term supply and large-volume production?

A7: Yes, we provide long-term supply contracts, ensuring consistent quality and reliable bulk production for large-scale projects.

Tags :

Whatsapp : +8617366266559

Email : sales@sunmayalu.com

Tel : +86 -17366266559

Hi! Click one of our members below to chat on