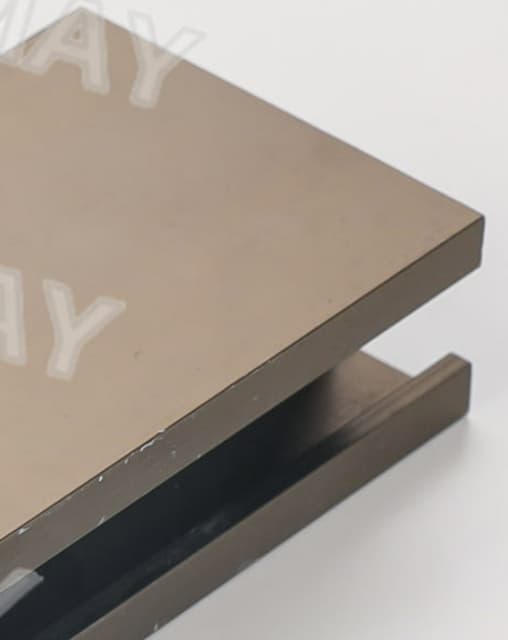

Durable champagne anodized aluminum profile with sandblasted surface, ideal for doors, windows, and modern architectural projects.

Material & Temper :

Custom Aluminum Alloy with Heat TreatmentApplication :

Architectural, Decorative Home and Industrial Aluminum ProfilesLead time :

10 to 30 daysExecutable Quality Standard :

GB5237, TS16949, EN12020, EN755, EN573, Or according to customer agreement standardsSurface Treatment :

Anodized SandblastedColor :

ChampagnePackaging method :

Customized according to customer requirementsThe champagne anodized aluminum profile is a premium building material made from high-strength aluminum alloy, treated with anodizing and champagne coloring. Its surface undergoes sandblasted aluminum extrusion processing, enhancing both aesthetic appeal and resistance to corrosion and wear. This profile maintains uniform color and structural stability over long-term use, reducing maintenance costs.

During design and production, Sunmay strictly controls every step—from extrusion to anodizing and sandblasting—ensuring compliance with international architectural standards. This process provides high surface adhesion and protective performance, making the durable aluminum profiles for architecture ideal for modern curtain walls, window frames, doors, and interior decoration.

| Feature/Property | Description | Customer Value |

|---|---|---|

| High Corrosion Resistance | Dual protection through anodizing and sandblasting, resisting moisture and pollution | Reduces maintenance and replacement costs, extends building service life |

| Elegant Finish | Champagne color combined with sandblasted texture for a premium appearance | Enhances overall project aesthetics, meeting high-end architectural requirements |

| Strength & Stability | Precision extrusion with high impact and load-bearing capacity | Ensures structural safety, suitable for high-rise and large-scale projects |

| Ease of Fabrication & Installation | Profiles allow easy cutting, welding, and assembly | Improves construction efficiency, saving labor and time |

| Environmental Sustainability | Aluminum is recyclable, produced through eco-friendly processes | Supports green building practices and certification requirements |

Compared to standard aluminum, the champagne anodized aluminum profile offers superior appearance and performance. The sandblasting process increases scratch and corrosion resistance, especially in humid or high-UV areas like South America and Europe. Sandblasted aluminum extrusion also ensures dimensional stability, perfectly compatible with coatings and sealants. For clients pursuing long-term investment returns, durable aluminum profiles for architecture provide both reliability and aesthetic excellence.

| Customer Pain Point | Solution |

|---|---|

| Profiles prone to corrosion | Anodizing and sandblasting provide enhanced corrosion resistance |

| Unattractive appearance | Champagne sandblasted finish delivers premium aesthetics |

| Low construction efficiency | High precision profiles allow fast and easy installation |

| Structural instability over time | High-strength profiles with excellent thermal stability ensure safety |

| Unreliable supplier delivery | Strict quality control and stable supply chain guarantee on-time delivery |

Clients often focus on material durability, appearance, and installation efficiency. The champagne anodized aluminum profile solves corrosion issues, sandblasted aluminum extrusion enhances aesthetics, and durable aluminum profiles for architecture provide strength and stability, ensuring long-term project safety.

The champagne anodized aluminum profile is suitable for modern construction and engineering projects, offering excellent performance and aesthetics for contractors and buyers:

Sunmay has a mature production and supply chain system, flexibly scheduling champagne anodized aluminum profile and sandblasted aluminum extrusion production according to project timelines. Each batch undergoes strict dimensional, surface, and corrosion tests to meet international architectural standards. With rich international logistics experience covering South America, Europe, Africa, and North America, Sunmay provides export documentation, customs support, and transportation solutions to ensure safe, timely delivery, helping contractors maintain project schedules.

Sunmay delivers high-quality champagne anodized aluminum profile and sandblasted aluminum extrusion with advanced extrusion, precision cutting, and surface treatment lines. Every batch undergoes strict quality control. The experienced team provides end-to-end technical support, accommodating large-scale projects and small-batch custom orders, ensuring stable supply for global markets and earning wide industry recognition.

Sunmay offers flexible customization of champagne anodized aluminum profile and sandblasted aluminum extrusion. Clients can specify cross-section, dimensions, wall thickness, and surface treatment. The process includes technical review, 3D design verification, and prototype testing. In real projects, customized profiles enhanced aesthetics and reduced maintenance for commercial complexes and high-end residential buildings, demonstrating high responsiveness and reliability.

Sunmay provides a structured OEM/ODM process for international clients. Initial communication evaluates specifications, material requirements, and process characteristics. Sample development and adjustments ensure compliance with customer standards. Production follows strict schedules and quality control. Project managers offer real-time updates on production, logistics, and QC reports. Full-service support, including packaging, customs documentation, and shipment planning, ensures on-time delivery and reduces risks for construction projects.

Tags :

Whatsapp : +8617366266559

Email : sales@sunmayalu.com

Tel : +86 -17366266559

Hi! Click one of our members below to chat on