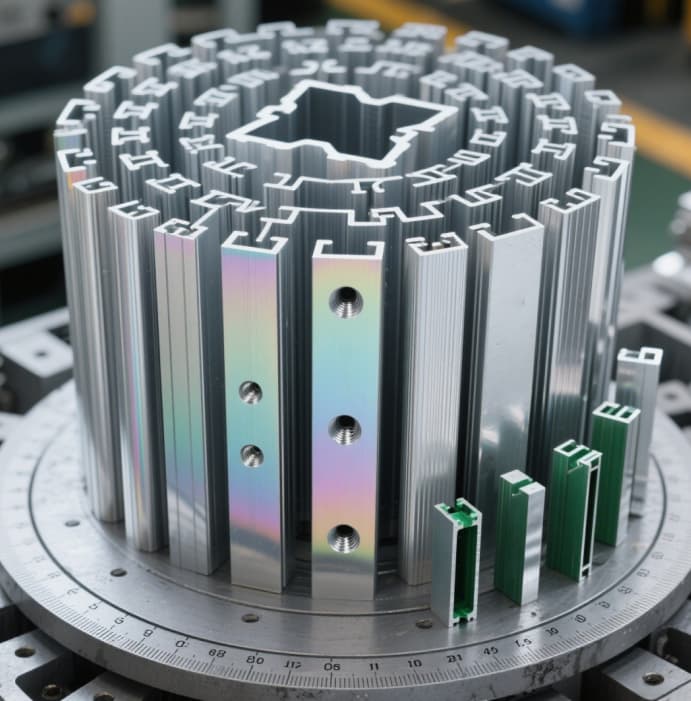

Professional CNC machining for aluminum parts with high precision and durability, ideal for industrial applications, construction, and custom projects.

Material & Temper :

Custom Aluminum Alloy with Tempering ProcessLength :

By Custom LengthApplication :

Automotive, Electronics Industry, Construction IndustryLead time :

10 to 30 daysExecutable Quality Standard :

GB5237, TS16949, EN12020, EN755, EN573, Or according to customer agreement standardsSurface Treatment :

Anodizing/Powder Coating/Brushing/PaintingColor :

Silver, Champagne, Brown, Bronze, Black, GoldenPackaging method :

Customized according to customer requirementsSunmay offers high-precision CNC aluminum machining services for a wide range of industrial and construction applications. Our precision aluminum parts are crafted from high-strength aluminum alloys, providing lightweight, corrosion-resistant, and robust performance to meet demanding project requirements.

With optimized structural designs, we ensure dimensional accuracy and assembly compatibility according to customer drawings. Advanced CNC equipment enables complex geometries including multi-hole, multi-surface, and curved parts while maintaining strict tolerance control. Surface treatments such as anodizing, sandblasting, and polishing enhance durability and aesthetic appeal, meeting the highest industry standards. Each custom aluminum fabrication product undergoes rigorous quality inspection, ensuring it fulfills project demands for both small-scale prototypes and large-scale production.

| Core Feature | Advantage |

|---|---|

| High-Precision Machining | Achieves ±0.01mm tolerance, ensuring dimensional stability and reducing assembly adjustments. |

| Reliable Material | High-strength aluminum alloy combines lightweight design with corrosion resistance, extending service life and reducing maintenance. |

| Versatile Surface Treatments | Anodizing, sandblasting, and polishing improve both appearance and durability for diverse applications. |

| Flexible Customization | Supports tailored machining according to client drawings and specifications, suitable for industrial and construction projects. |

| Fast Delivery | Standardized production and inventory management enable prompt delivery, supporting urgent project needs. |

Sunmay’s CNC aluminum machining solutions focus not only on product precision and material performance but also on solving client challenges in cost, project timelines, and supply chain management. Advanced machining minimizes on-site adjustments, flexible customization accommodates project changes, and versatile surface treatments provide both aesthetic and functional reliability.

| Customer Pain Point | Sunmay Solution |

|---|---|

| Dimensional Accuracy Issues | Advanced CNC machines and multi-point inspection ensure every batch meets ±0.01mm tolerance standards. |

| Long Lead Times | Standardized production and flexible scheduling enable quick completion of small and large orders. |

| Inconsistent Material Quality | Strict material selection and testing guarantee aluminum alloy strength, corrosion resistance, and consistency. |

| Uneven Surface Finishing | Automated surface treatment processes ensure uniform appearance and long-lasting durability. |

Clients often face challenges such as misaligned precision aluminum parts, delayed delivery, or unstable material strength. Sunmay addresses these by controlling every stage—from material sourcing, design verification, precision machining, to surface finishing—ensuring that delivered parts meet project requirements and significantly reduce rework and onsite adjustments.

Sunmay’s custom aluminum fabrication services ensure high efficiency and reliability across diverse industries and project environments, from small-scale prototypes to large engineering projects.

Sunmay possesses a mature project management system and global export qualifications. From drawing verification, material procurement, CNC machining, to inspection and packaging, every stage is standardized. Flexible scheduling and inventory management ensure timely delivery, while export documentation and logistics tracking support projects in South America, Europe, Africa, and North America. Our experienced team ensures full compliance with international trade standards.

Q1: What are precision aluminum parts used for?

A: Precision aluminum parts are widely used in construction, automotive, aerospace, and industrial machinery. Their high strength-to-weight ratio, corrosion resistance, and dimensional accuracy make them ideal for structural, decorative, and functional components.

Q2: How are precision aluminum parts manufactured?

A: They are produced using CNC aluminum machining, which ensures high accuracy and repeatability. Custom aluminum fabrication techniques and surface treatments like anodizing enhance durability and appearance.

Q3: How to choose a reliable CNC aluminum machining supplier?

A: Look for certified quality management, advanced CNC equipment, experience in custom fabrication, and capability to handle both small and large projects. Transparency and timely delivery are essential.

Sunmay operates advanced CNC machining centers and automated surface treatment equipment, supported by a rigorous quality management system covering materials to finished products. Our experienced engineering team responds quickly to client requirements, ensuring each CNC aluminum machining part meets international standards. This enables Sunmay to deliver reliable, high-quality aluminum parts to global buyers.

Sunmay provides flexible customization from drawing review, sample production, design optimization to full-scale machining. We handle complex geometries, multi-surface, and curved components, while tailoring materials and surface treatments to project requirements. Successful projects include architectural aluminum profiles, industrial machinery components, and lightweight transportation parts, demonstrating the efficiency and reliability of our custom aluminum fabrication services.

Collaboration includes:

1. Requirement Communication: Clients provide drawings and specifications; Sunmay performs technical evaluation.

2. Design & Quotation: Custom machining plans, material selection, and cost optimization.

3. Sample Approval: Rapid prototyping for size, function, and surface verification.

4. Mass Production: Batch manufacturing following approved samples and processes.

5. Inspection & Delivery: Strict quality checks, on-time delivery, and export documentation support.

This process ensures professional, efficient service for all precision aluminum parts and custom aluminum fabrication projects.

Q1: What is CNC aluminum machining?

A: CNC aluminum machining is a computer-controlled process to cut, mill, drill, and shape aluminum parts with high precision. It ensures tight tolerances and repeatable results, ideal for industrial and construction applications.

Q2: Can you provide custom aluminum fabrication for small orders?

A: Yes, Sunmay supports both small and large batch orders. Our flexible CNC machining allows precise production regardless of order size, maintaining consistent quality.

Q3: What surface treatments are available?

A: We provide anodizing, powder coating, polishing, and sandblasting to enhance corrosion resistance, appearance, and durability of precision aluminum parts.

Q4: How is dimensional accuracy ensured?

A: Advanced CNC equipment and multi-point inspections ensure every part meets ±0.01mm tolerance standards.

Q5: Which industries use precision aluminum parts?

A: Construction, industrial machinery, automotive, aerospace, electronics, and renewable energy industries rely on high-quality aluminum parts for structural, functional, and decorative applications.

Q6: How fast can Sunmay deliver custom aluminum parts?

A: Standardized production and inventory management enable rapid turnaround. Small orders can be delivered within days, and bulk orders follow structured schedules for on-time delivery.

Q7: How does Sunmay handle OEM/ODM projects?

A: We provide end-to-end support from design consultation, sample verification, to mass production and logistics, ensuring custom aluminum fabrication projects meet quality and timeline requirements.

Tags :

Whatsapp : +8617366266559

Email : sales@sunmayalu.com

Tel : +86 -17366266559

Hi! Click one of our members below to chat on