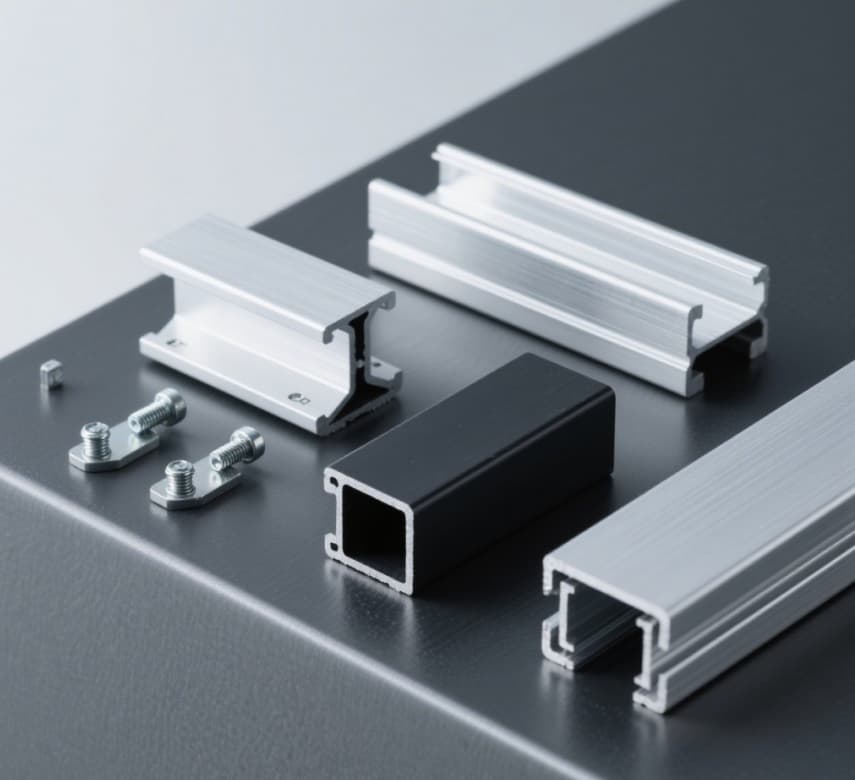

High-quality aluminum CNC machined components designed for durability and accuracy, ideal for construction, machinery, and custom engineering projects.

Material & Temper :

Custom Aluminum Alloy with Tempering ProcessLength :

By Custom LengthApplication :

Automotive, Electronics Industry, Construction IndustryLead time :

10 to 30 daysExecutable Quality Standard :

GB5237, TS16949, EN12020, EN755, EN573, Or according to customer agreement standardsSurface Treatment :

Anodizing/Powder Coating/Brushing/PaintingColor :

Silver, Champagne, Brown, Bronze, Black, GoldenPackaging method :

Customized according to customer requirementsOur aluminum CNC machining parts are crafted from high-grade alloys such as 6061, 6063, and 7075, offering excellent strength-to-weight ratio, corrosion resistance, and stability under demanding industrial conditions. Every batch of raw material undergoes stringent inspection to ensure reliable performance in construction, machinery, and engineering projects.

Equipped with advanced CNC machining centers, we produce precision CNC aluminum components with tight tolerances and complex geometries. Processes including milling, turning, drilling, and threading allow us to meet both standard and custom requirements, ensuring consistent quality for small and large batches. Surface treatments such as anodizing, powder coating, sandblasting, and polishing enhance durability and aesthetic appeal. These options make our custom aluminum machined parts suitable not only for industrial applications but also for high-end consumer products. All components comply with ISO 9001 standards, with additional CE or RoHS certification available upon request.

| Feature | Description | Customer Benefit |

|---|---|---|

| High Precision Machining | CNC milling, turning, drilling with ±0.01mm tolerance | Ensures perfect fit, reduces assembly issues |

| Premium Aluminum Alloys | 6061, 6063, 7075 | Lightweight, strong, and corrosion-resistant components |

| Flexible Surface Finishes | Anodizing, powder coating, sandblasting | Durable parts with professional appearance |

| ISO-Certified Production | ISO 9001, CE, RoHS compliance | Reliable quality for global projects |

| Quick Turnaround | Small to large batch production | Short lead times for urgent requirements |

Our aluminum CNC machining parts integrate high-grade materials with precision engineering to deliver outstanding performance. Using advanced CNC equipment ensures that precision CNC aluminum components meet strict dimensional tolerances, reducing secondary processing and saving both time and cost. For diverse customer needs, flexible surface treatments allow tailored finishes to meet functional and aesthetic requirements. ISO-certified processes and multi-stage inspections guarantee that every custom aluminum machined part meets international standards, delivering consistent performance across construction, machinery, and engineering applications.

| Customer Pain Point | Solution | Benefit |

|---|---|---|

| Unstable Delivery Times | Digital production planning & scalable batch production | Reliable supply and on-time delivery |

| Quality Variations | ISO-certified production & multi-stage inspection | Consistent precision, reduced rework |

| High Production Costs | Efficient CNC machining | Cost-effective solutions without compromising quality |

| Communication Barriers | Dedicated technical & sales support | Faster response and accurate project alignment |

| Complex Custom Requirements | Flexible prototyping & customization | Parts tailored to exact specifications with quick iterations |

Clients in construction, machinery, and engineering often face challenges such as fluctuating delivery schedules, inconsistent quality, and high costs. Our aluminum CNC machining parts are designed to directly solve these problems. Digital production scheduling and flexible batch sizes ensure reliable delivery. Multi-stage inspection and ISO certification guarantee that precision CNC aluminum components meet exact tolerances, reducing assembly errors. Advanced CNC machining minimizes waste and secondary processing costs, allowing custom aluminum machined parts to be supplied competitively. Dedicated technical teams ensure smooth communication and rapid prototyping, enabling precise customization for each project. This ensures components integrate seamlessly into the client's supply chain, addressing quality, cost, and timing concerns.

Used in curtain walls, handrails, and window frames, our aluminum CNC machining parts offer durability in humid and coastal environments. In a Brazilian residential project, over 5,000 components were delivered with ±0.02mm tolerances, fully meeting design specifications.

Our precision CNC aluminum components serve as brackets, gears, and housings. In Kenya, we supported a mechanical assembly line with custom components optimized for heavy loads, ensuring reliability and low maintenance.

For rail and automotive projects, dimensional accuracy and surface finish are crucial. Our custom aluminum machined parts were supplied for a German rail project, providing lightweight, anodized components meeting strict safety standards.

High-end electronics require precise housings. We delivered precision CNC aluminum components with anodized and polished finishes, combining aesthetics with mechanical performance.

Our aluminum CNC machining parts are used in wind turbines and solar panels, offering corrosion-resistant, lightweight, and precisely machined solutions suitable for harsh environments.

We manage large projects, often shipping thousands of precision CNC aluminum components globally. ISO-certified production and advanced logistics ensure on-time delivery via sea or air freight. Clients in Europe, Africa, and South America rely on our scalable production, transparent tracking, and professional export support.

Sunmay operates advanced CNC machining facilities with multi-axis milling and turning centers. Quality control includes CMM inspections and full traceability. Our experienced engineers ensure each custom aluminum machined part meets technical and aesthetic requirements, supporting clients worldwide.

We provide tailored solutions from prototypes to mass production, including material selection, surface treatment, and dimensional adjustments. Clients in Europe prefer anodized finishes, while South American clients focus on cost-effective designs. Flexible prototyping ensures rapid iterations and precise results for all aluminum CNC machining parts.

7-Step Process:

Q1: What are aluminum CNC machining parts used for?

They are used in construction, machinery, automotive, electronics, and renewable energy applications where precision and durability are required.

Q2: How precise are precision CNC aluminum components?

Tolerances as tight as ±0.01mm are achievable, ensuring perfect fit and reducing secondary processing.

Q3: Can I order custom aluminum machined parts in small quantities?

Yes, flexible batch sizes are available, including prototypes before full-scale production.

Q4: What surface finishes are available?

Options include anodizing, powder coating, sandblasting, and polishing to meet functional and aesthetic requirements.

Q1: What is the minimum order quantity?

MOQ depends on complexity; small-batch prototypes are supported.

Q2: How is precision ensured?

All precision CNC aluminum components undergo multi-stage inspection including CMM and visual checks.

Q3: Can I request custom packaging?

OEM packaging and labeling are available according to requirements.

Q4: Are samples available?

Yes, samples can be produced for verification with expedited delivery options.

Q5: How long is the lead time?

Typically 2–6 weeks depending on order size and complexity; large projects are scheduled with clear timelines.

Q6: What certifications are provided?

ISO 9001 is standard; CE, RoHS, or customer-specific certificates are available.

Q7: Can you handle urgent orders?

Yes, flexible scheduling and scalable production allow urgent orders without compromising quality.

Q8: How do you support international clients?

Dedicated export teams manage logistics, customs, and technical support for smooth delivery worldwide.

Q9: Which industries benefit most?

Construction, machinery, automotive, electronics, renewable energy, and industrial equipment sectors rely on our high-quality components.

Whatsapp : +8617366266559

Email : sales@sunmayalu.com

Tel : +86 -17366266559

Hi! Click one of our members below to chat on