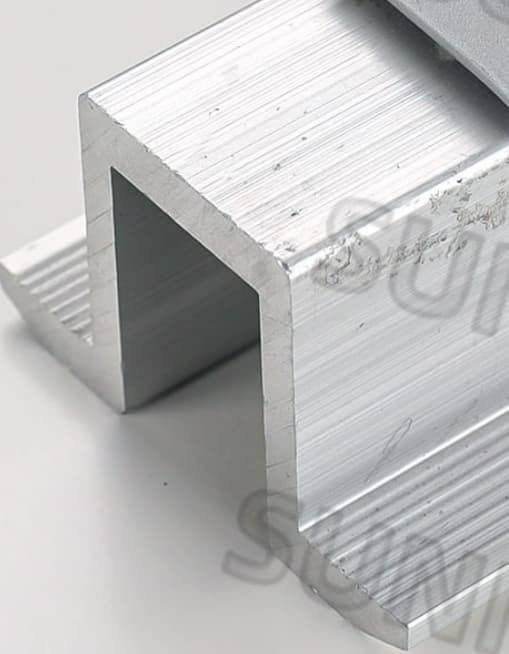

Premium CNC machined aluminum parts with tight tolerances, durable alloys, and versatile applications for construction, machinery, automotive, and engineering projects.

Material & Temper :

Custom Aluminum Alloy with Tempering ProcessLength :

By Custom LengthApplication :

Automotive, Electronics Industry, Construction IndustryLead time :

10 to 30 daysExecutable Quality Standard :

GB5237, TS16949, EN12020, EN755, EN573, Or according to customer agreement standardsSurface Treatment :

Anodizing/Powder Coating/Brushing/PaintingColor :

Silver, Champagne, Brown, Bronze, Black, GoldenPackaging method :

Customized according to customer requirementsOur CNC aluminum machining services provide durable, high-performance components manufactured from premium aluminum alloys such as 6061, 6063, and 7075. These materials ensure excellent strength-to-weight ratios, corrosion resistance, and longevity for industrial, automotive, and construction projects.

Each precision aluminum component is produced with strict tolerances, advanced multi-axis CNC milling, turning, and drilling techniques. Our custom machined aluminum parts can be tailored to complex geometries, including threaded holes, intricate contours, and precise slots, providing seamless integration into your assemblies. Surface treatments like anodizing, powder coating, sandblasting, and polishing enhance durability and aesthetics, making components suitable for harsh environments. Every step follows ISO 9001 standards, ensuring repeatable quality for international industrial applications.

| Feature | Description | Customer Benefit |

|---|---|---|

| High Precision Machining | Multi-axis CNC with ±0.01mm tolerance | Reduces assembly errors and ensures consistent performance |

| Premium Aluminum Alloys | 6061, 6063, 7075 | Lightweight, corrosion-resistant, and long-lasting parts |

| Flexible Surface Finishes | Anodizing, powder coating, polishing | Enhanced durability, aesthetics, and corrosion protection |

| ISO-Certified Processes | ISO 9001 compliant, CE & RoHS optional | Reliable quality for global projects |

| Scalable Production | Prototype to high-volume orders | Fast turnaround without compromising quality |

By combining CNC aluminum machining with advanced inspection systems, clients receive precision aluminum components that reduce production errors, optimize costs, and support global supply chains. Customization capabilities allow custom machined aluminum parts to meet specific project requirements across industries.

| Customer Pain Point | Solution | Benefit |

|---|---|---|

| Quality Variability | Multi-stage QC inspection including CMM | Consistent precision and reduced rework |

| Complex Designs | Flexible prototyping and iterative adjustments | Accurate, tailored parts for unique projects |

| Delivery Delays | Advanced production scheduling and logistics | On-time global delivery |

| High Production Costs | Optimized CNC operations and material usage | Cost-effective manufacturing without sacrificing quality |

| Communication Gaps | Dedicated technical support and project managers | Clear project alignment and fast responses |

Our custom machined aluminum parts are designed to solve these challenges, providing reliable solutions for construction, automotive, machinery, and electronics industries. Clear communication and robust QC systems ensure smooth project execution worldwide.

CNC aluminum machining is widely used in window frames, door panels, and façade elements in Brazil and Argentina. Our precision components meet strict dimensional and aesthetic standards for large-scale projects.

Precision aluminum components serve as gears, housings, and brackets for Kenyan and South African factories, offering strength, corrosion resistance, and longevity under heavy load conditions.

German and Spanish manufacturers use our custom machined aluminum parts in vehicle assemblies, lightweight frames, and engine components, ensuring compliance with safety and performance standards.

Our precision aluminum components provide heat sinks, housings, and mounts for electronics in the US and Canada, combining dimensional accuracy, thermal efficiency, and polished finishes.

CNC aluminum machining parts are applied in solar panels and wind turbines, offering durability, corrosion resistance, and stable performance in harsh climates worldwide.

Sunmay handles thousands of precision aluminum components shipped globally. ISO-certified production ensures high-quality output, while logistics expertise guarantees on-time delivery via sea, air, or express freight, supported by complete documentation for customs clearance.

Sunmay operates advanced CNC centers, including multi-axis milling and turning machines. Integrated quality control with CMM inspection, in-process checks, and traceable production records ensures every custom machined aluminum part meets client specifications. Experienced engineers and production teams provide technical support and project optimization guidance.

From material selection, dimensional specifications, to surface treatment, we offer end-to-end customization. European clients often require anodized and polished finishes, while South American clients prioritize cost-efficient solutions. Rapid prototyping and agile production enable precise, project-specific CNC aluminum machining solutions.

Q1: What are CNC aluminum machining parts used for?

They are essential in construction, automotive, machinery, and electronics for high-precision and durable applications.

Q2: How accurate are precision aluminum components?

Tolerances up to ±0.01mm ensure proper fit, reducing assembly errors and post-processing requirements.

Q3: Can I order custom machined aluminum parts in small quantities?

Yes, we support prototypes and small-batch production before full-scale orders.

Q4: What surface finishes are available?

Anodizing, powder coating, sandblasting, and polishing are offered to meet both functional and aesthetic requirements.

Q1: What is the minimum order quantity?

MOQ varies by design complexity; small-batch prototypes are supported.

Q2: How is precision ensured?

Every precision aluminum component undergoes multi-stage inspection including CMM measurement.

Q3: Can I request custom packaging?

OEM packaging and labeling options are available.

Q4: Are samples available?

Yes, expedited samples can be provided.

Q5: Typical lead times?

2–6 weeks depending on order size and complexity.

Q6: Certifications?

ISO 9001 standard, CE, RoHS, or client-specific certificates upon request.

Q7: Urgent orders?

Flexible scheduling ensures urgent orders are delivered without compromising quality.

Q8: International support?

Dedicated export teams manage logistics, customs, and technical support.

Q9: Which industries benefit most?

Construction, machinery, automotive, electronics, renewable energy, and industrial equipment sectors rely on our components.

Tags :

Whatsapp : +8617366266559

Email : sales@sunmayalu.com

Tel : +86 -17366266559

Hi! Click one of our members below to chat on