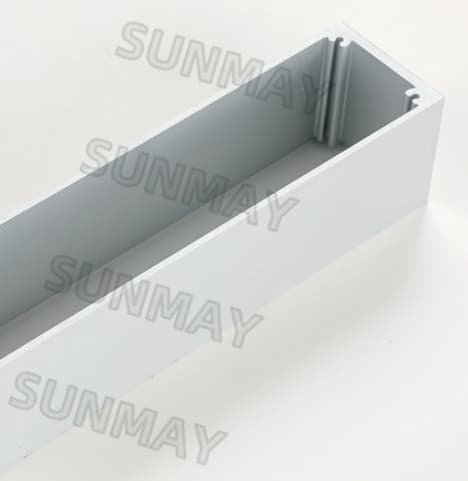

Sunmay provides high-precision CNC machining for custom aluminum parts, ensuring tight tolerances, smooth finishes, and durable performance for industrial and construction applications.

Material & Temper :

Custom Aluminum Alloy with Tempering ProcessLength :

By Custom LengthApplication :

Automotive, Electronics Industry, Construction IndustryLead time :

10 to 30 daysExecutable Quality Standard :

GB5237, TS16949, EN12020, EN755, EN573, Or according to customer agreement standardsSurface Treatment :

Anodizing/Powder Coating/Brushing/PaintingColor :

Silver, Champagne, Brown, Bronze, Black, GoldenPackaging method :

Customized according to customer requirementsSunmay offers custom aluminum parts with advanced precision CNC machining services, designed for industrial, construction, and mechanical equipment applications. Our products are made from premium aluminum alloys and processed using state-of-the-art aluminum CNC machining technology, ensuring smooth surfaces, exact tolerances, and excellent corrosion resistance. Each part undergoes multiple inspections to guarantee compliance with international standards, providing high durability and performance.

We employ 3-axis, 4-axis, and 5-axis CNC machines capable of handling complex geometries, deep holes, and multi-surface machining. These precision aluminum components achieve micron-level accuracy, ideal for high-end industrial and precision machinery applications. Various surface treatments, including anodizing, sandblasting, and powder coating, are available to ensure exceptional performance in diverse environments.

| Feature | Advantage | Customer Value |

|---|---|---|

| High Precision Machining | Micron-level tolerance control | Minimizes assembly errors and enhances equipment performance |

| Multiple Surface Treatments | Anodizing, sandblasting, powder coating | Improves corrosion resistance and aesthetics, extends part life |

| Custom Design | Manufactured based on customer drawings or 3D models | Meets complex project requirements and improves efficiency |

| Fast Delivery | Optimized production management system | Shortens supply chain and reduces inventory costs |

These advantages of aluminum CNC machining improve part reliability while reducing customer costs and supply chain risks. The high accuracy and durability of precision aluminum components provide solid support for engineering projects.

| Common Issue | Sunmay Solution |

|---|---|

| Inaccurate part dimensions | Multi-axis CNC machining ensures micron-level accuracy for smooth assembly |

| Material durability insufficient | High-strength aluminum alloy with anodizing or sandblasting enhances corrosion resistance |

| Long lead times | Optimized production and inventory management ensure on-time delivery |

| Customization requirements difficult | Professional design team supports production based on drawings or 3D models |

Sunmay has extensive experience delivering large-scale projects worldwide. Our complete export certifications and international logistics expertise support ocean, air, and land shipments. Through rigorous production planning and quality control, each batch of custom aluminum parts is delivered on time, compliant with destination country standards, and tracked throughout the supply chain.

Since establishment, Sunmay has focused on high-precision aluminum part manufacturing. Our factory is equipped with advanced CNC machining centers (3-axis, 4-axis, 5-axis), CNC lathes, and precision grinders. The quality control system covers raw material inspection, production monitoring, and finished product testing. Our professional team can handle complex machining challenges, delivering reliable aluminum CNC machining services.

Sunmay provides flexible customization based on market differences and customer needs. Whether industrial machinery components, construction structural parts, or aerospace assemblies, we can produce according to drawings or 3D models. Fast response and flexible processing allow customers to maintain market advantage while minimizing inventory and production costs.

Q1: What types of custom aluminum parts does Sunmay produce?

A1: Sunmay manufactures a wide range of industrial, construction, and machinery parts, including complex structures and high-precision components.

Q2: What accuracy can CNC machining achieve?

A2: Using advanced multi-axis CNC equipment, precision aluminum components reach micron-level accuracy.

Q3: Do you offer bulk production and fast delivery?

A3: Yes, with complete production lines and logistics systems, we support large-scale orders and on-time delivery.

Q1: Can parts be machined directly from 3D models?

A1: Yes, Sunmay provides production based on 3D models, ensuring precise dimensions.

Q2: What surface treatment options are available?

A2: Anodizing, sandblasting, and powder coating enhance corrosion resistance and aesthetics.

Q3: What is the minimum batch size for CNC parts?

A3: Depending on complexity, both small and large batches are supported.

Q4: How long for overseas shipping?

A4: Sea shipments usually take 30–45 days, air shipments 5–10 days, with full tracking available.

Q5: How is part quality ensured?

A5: Every part undergoes raw material inspection, production monitoring, and final testing to meet international standards.

Tags :

Whatsapp : +8617366266559

Email : sales@sunmayalu.com

Tel : +86 -17366266559

Hi! Click one of our members below to chat on