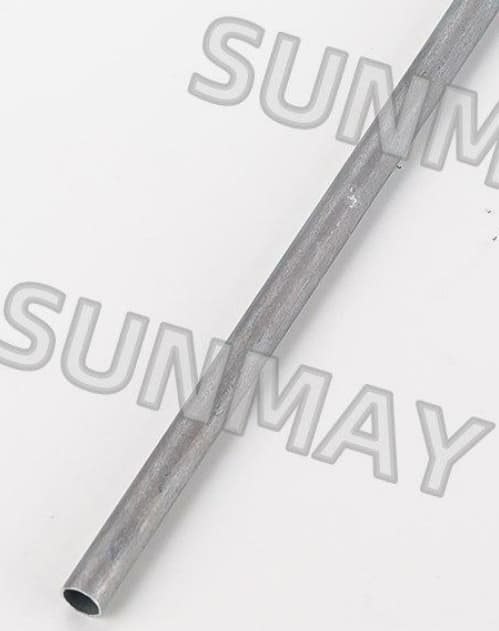

High-strength seamless aluminum profile pipes designed for durable and precise construction applications, ideal for architectural, industrial, and infrastructure projects.

Material & Temper :

A53/A106Application :

Construction, machine, medical etcLead time :

10 to 30 daysExecutable Quality Standard :

According to customer agreement standardsPackaging method :

According to customer agreement standardsSpecifications :

SeamlessDiameter :

6.4 millimetersOur seamless aluminum profile pipe is made of high-strength aluminum alloy, manufactured through advanced hot extrusion technology. The pipe surface is smooth and weld-free, ensuring structural stability and long-term durability in construction applications. Each pipe undergoes rigorous dimensional control and mechanical performance testing, meeting international building standards and providing excellent bending and compressive strength, suitable for high-rise buildings, industrial facilities, and bridge structures.

Specially, our construction aluminum pipe adopts precision extrusion and high-temperature aging treatment, enhancing surface hardness and corrosion resistance. It effectively withstands humid coastal conditions in South America and temperature variations in North America. Custom diameters and wall thicknesses are available to meet different project design requirements, ensuring efficient and safe installation. For projects requiring aesthetic appeal, we offer anodized or powder-coated finishes, providing uniform color and excellent oxidation resistance. Whether for indoor decoration or outdoor structures, our architectural aluminum profile delivers reliable and visually appealing solutions.

| Feature | Advantage | Customer Value |

|---|---|---|

| High-strength seamless design | No welds reduce stress concentration, ensuring load capacity | Enhanced construction safety, lower maintenance costs |

| Precision extrusion | High dimensional accuracy, customizable as per project needs | Reduces construction errors, saves material costs |

| Corrosion-resistant surface | Anodized or powder-coated finish prolongs service life | Adaptable to various environments, reduces replacement frequency |

| Customizable specifications | Flexible diameter, wall thickness, and length | Meets different architectural project requirements |

| Lightweight | Aluminum design eases handling and installation | Lower transportation costs, increased construction efficiency |

These advantages help clients improve construction efficiency and reduce rework due to material issues. In a large-scale Brazilian commercial project, our pipes exceeded 15 years of expected service life and improved installation efficiency by 20%.

| Pain Point | Solution | Case Example |

|---|---|---|

| Pipe corrosion | Anodized or powder-coated treatment | Chilean coastal hotel project: Salt spray resistance exceeds 1000 hours |

| Non-standard dimensions causing installation issues | Precision extrusion, supports custom diameters and wall thickness | Argentinian bridge project: Customized pipes fit design perfectly |

| Heavy weight, difficult handling | Lightweight aluminum design | Peruvian industrial project: Single-person handling reduces labor cost |

| Long supply cycle | Comprehensive inventory and logistics system | South American real estate client: Rapid bulk delivery shortens schedule |

| Quality fluctuations | Strict QC system, batch testing | Chilean commercial complex: Each batch passed compression, bending, and surface checks |

These measures allow clients to effectively address construction challenges while ensuring project quality and safety.

Sunmay has a robust logistics system and export certification, capable of delivering large volumes of pipes efficiently. Each batch is labeled, measured, and quality-checked to meet specifications. We are familiar with South American, European, and North American import standards and provide complete export documentation, including certificates of origin and quality reports. Previous projects, such as São Paulo commercial complexes and Argentine bridges, involved over 1,000 tons of pipes delivered on schedule with high client satisfaction.

Sunmay’s factory is equipped with advanced aluminum extrusion equipment and automated production lines, with strict QC processes and experienced production teams. Real-time monitoring ensures dimensional accuracy, surface quality, and mechanical performance meet international standards. Our R&D team continuously optimizes pipe performance for different market needs. Annual production exceeds 30,000 tons, meeting large-scale project demands across South America, Europe, and North America.

Sunmay supports custom diameters, wall thicknesses, lengths, and surface finishes. We provide optimized solutions based on project environment and installation requirements:

Sample confirmation is typically 3–7 days, ensuring project schedules are maintained.

Q1: What are the benefits of seamless aluminum profile pipes in construction?

A1: Seamless pipes provide higher structural strength and corrosion resistance compared to welded pipes, ideal for residential and commercial projects.

Q2: Can construction aluminum pipes be customized?

A2: Yes, they can be tailored in diameter, wall thickness, and surface finish to match project requirements.

Q3: How durable are architectural aluminum profiles?

A3: With anodized or powder-coated finishes, they can withstand harsh conditions for 15+ years.

Q1: What standard specifications do your seamless aluminum profile pipes meet?

A1: Compliant with ASTM and ISO standards, ensuring high strength, precise dimensions, and corrosion resistance for international construction projects.

Q2: Can you provide bulk shipments to South America?

A2: Yes, with experience delivering thousands of tons to Brazil, Chile, and Argentina, complete with export documentation.

Q3: How quickly can custom pipes be delivered?

A3: Sample confirmation takes 3–7 days; bulk production is about 2–4 weeks depending on order volume.

Q4: Are your pipes suitable for outdoor coastal projects?

A4: Absolutely, anodized and powder-coated finishes provide excellent resistance to humidity, salt spray, and UV exposure.

Q5: Do you offer technical support for installation?

A5: Yes, our engineers provide guidance on installation, structural support, and maintenance for safe and efficient use.

Whatsapp : +8617366266559

Email : sales@sunmayalu.com

Tel : +86 -17366266559

Hi! Click one of our members below to chat on