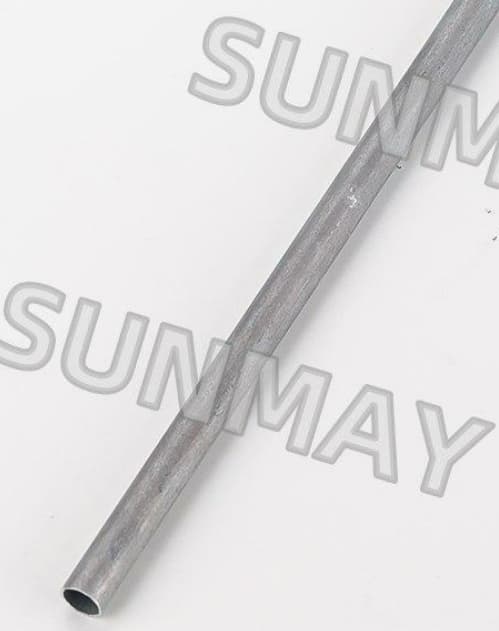

High-strength seamless aluminum pipe designed for construction and industrial projects. Durable, corrosion-resistant, and lightweight for long-term reliable performance.

Material & Temper :

A53/A106Application :

Construction, machine, medical etcLead time :

10 to 30 daysExecutable Quality Standard :

According to customer agreement standardsPackaging method :

According to customer agreement standardsSpecifications :

SeamlessDiameter :

8.5 millimetersOur seamless aluminum pipe is engineered for superior performance in construction and industrial applications. Using advanced extrusion and heat-treatment techniques, each pipe ensures precise dimensions, consistent surface finish, and enhanced structural integrity. The lightweight nature of aluminum combined with its high resistance to corrosion makes it a preferred choice for projects in humid, coastal, or high-temperature environments.

Unlike conventional welded pipes, our seamless design reduces weak points and improves durability under high stress, making it ideal for demanding conditions in the construction, transportation, and industrial machinery sectors. Clients can expect stable quality, longer service life, and easy installation, which significantly reduces maintenance costs.

| Feature | Advantage |

|---|---|

| Seamless Structure | Eliminates welding weaknesses, ensuring higher strength for aluminum construction pipe. |

| Corrosion Resistance | Withstands exposure in coastal or industrial environments, reducing replacement frequency. |

| Lightweight & Strong | Balances strength and reduced weight, making transportation and installation easier. |

| Precision Dimensions | Supports exact fitting in structural systems, minimizing rework and waste. |

These advantages address critical issues such as project quality, long-term cost, and supply stability. For global contractors, choosing our industrial aluminum tube helps streamline project timelines while keeping budgets under control.

| Common Pain Point | Our Solution |

|---|---|

| Concerns about pipe durability | High-strength seamless design tested under extreme pressure. |

| Supply chain delays | Reliable export capacity with on-time delivery commitments. |

| Corrosion in outdoor projects | Surface treatments ensure long-term resistance to harsh weather. |

| Custom project requirements | Flexible OEM/ODM options to meet unique specifications. |

By targeting these issues, Sunmay helps buyers minimize risks and achieve consistent quality across international markets.

These examples demonstrate the global adaptability of our aluminum construction pipe, making it suitable for diverse industries and climates.

Sunmay has extensive experience in supplying seamless aluminum pipe for major international projects. With a logistics network covering South America, Europe, Africa, and North America, we ensure timely shipment and safe delivery. Our export documentation, certifications, and compliance support make international procurement smooth and efficient for buyers worldwide.

Our manufacturing facility is equipped with advanced extrusion lines, precision machining equipment, and automated quality inspection systems. Each industrial aluminum tube undergoes rigorous testing, including pressure, corrosion, and dimensional accuracy checks. The Sunmay team of engineers and technicians focuses on continuous innovation, ensuring clients receive not only high-quality products but also reliable technical support.

Different markets have unique requirements. For example, South American clients often demand larger pipe diameters for infrastructure projects, while European buyers focus on surface finishing and eco-friendly compliance. Sunmay provides flexible customization options, from wall thickness adjustments to special alloy compositions, helping clients win more competitive bids in their regions.

This structured process ensures efficient communication and reliable outcomes for international buyers.

What is a seamless aluminum pipe used for?

It is mainly used in construction, industrial frameworks, pipelines, and transportation projects requiring durability and lightweight strength.

How does a seamless aluminum pipe differ from a welded pipe?

A seamless pipe has no weld seams, providing higher strength, better corrosion resistance, and longer service life.

Can seamless aluminum pipes be customized?

Yes, Sunmay offers customization in diameter, wall thickness, and alloy selection to meet diverse project requirements.

Q1: What industries commonly use seamless aluminum pipes?

They are widely applied in construction, infrastructure, automotive, aerospace, and manufacturing industries.

Q2: How do seamless aluminum pipes perform in coastal environments?

Thanks to corrosion resistance, they maintain structural integrity even under humid and salty air conditions.

Q3: Can you provide bulk orders for large-scale projects?

Yes, Sunmay specializes in handling large orders with consistent quality and on-time delivery across global markets.

Q4: Do you offer OEM/ODM support?

Absolutely, we provide flexible OEM/ODM solutions to meet customized requirements.

Q5: What certifications do your products have?

Our products comply with international quality standards such as ISO and CE, ensuring reliability in different markets.

Tags :

Whatsapp : +8617366266559

Email : sales@sunmayalu.com

Tel : +86 -17366266559

Hi! Click one of our members below to chat on