Premium seamless aluminum profiles designed for durable construction, precision engineering, and versatile industrial applications worldwide.

Material & Temper :

A53/A106Application :

Construction, machine, medical etcLead time :

10 to 30 daysExecutable Quality Standard :

According to customer agreement standardsPackaging method :

According to customer agreement standardsSpecifications :

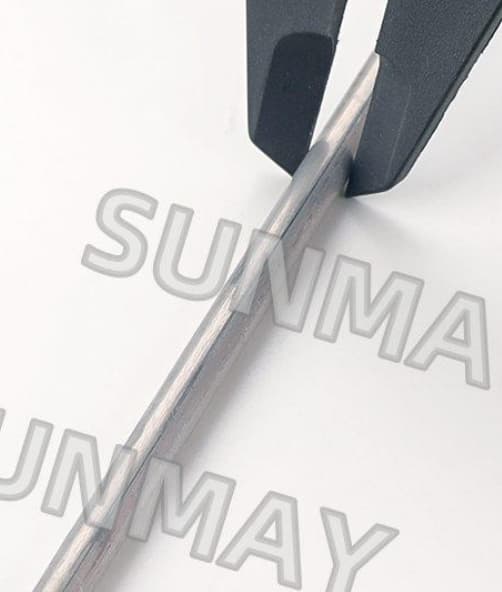

SeamlessDiameter :

5.0 millimetersSunmay provides high-quality seamless aluminum profiles designed for industrial and construction applications. Made from premium aluminum alloys, these profiles ensure strong structural integrity and long-lasting performance. Advanced extrusion techniques and surface treatments guarantee precise dimensions and superior corrosion resistance, meeting the stringent requirements of global industrial projects.

The profiles feature optimized cross-sectional designs, increasing load-bearing capacity while reducing weight for efficient handling and transportation. Anodized surface treatment enhances wear and corrosion resistance, providing a polished appearance suitable for high-end industrial projects, precision machinery, and architectural applications. Each batch undergoes strict quality control to ensure dimensional accuracy, surface finish, and mechanical performance, fulfilling the demands of industrial aluminum extrusions and high-quality aluminum construction worldwide.

| Key Feature | Advantage |

|---|---|

| High-strength aluminum alloy | Provides excellent structural support, reduces material usage, and enhances cost efficiency in construction projects. |

| Precision extrusion process | Ensures dimensional accuracy and geometric stability for easy assembly and installation. |

| Anodized surface treatment | Improves corrosion and wear resistance, extending service life for outdoor and industrial environments. |

| Customizable cross-sections | Meets specific project requirements, enhances installation efficiency, and reduces labor costs. |

| Batch consistency and stability | Ensures seamless integration in large-scale projects, improving structural safety and visual uniformity. |

Sunmay’s seamless aluminum profiles combine premium materials and precise manufacturing processes to help customers reduce costs and improve efficiency in construction and industrial applications. Lightweight yet strong, they are ideal for large-scale building and machinery projects. Anodized surfaces resist corrosion in outdoor or high-humidity environments, maintaining durability and aesthetics. Custom cross-section designs ensure precise installation, reduce material waste, and large-batch consistency guarantees seamless project delivery, meeting the high expectations of global procurement and trade clients.

| Customer Pain Point | Sunmay Solution |

|---|---|

| Insufficient material strength causing structural risks | High-strength aluminum alloy ensures long-term stability for industrial and construction projects. |

| Dimensional deviations affecting installation | Precision extrusion and rigorous quality control guarantee international-standard compliance. |

| Corrosion or oxidation issues | Anodized surface treatment enhances durability and reduces maintenance needs. |

| Special cross-section requirements | Flexible customization options meet diverse industrial and architectural demands. |

Procurement and construction clients often face issues with weak materials, size inconsistencies, and corrosion. Sunmay solves these problems using high-strength aluminum and precision extrusion processes. Surface anodization ensures long-term durability even in harsh environments. Flexible custom cross-sections allow clients to receive profiles tailored to project needs, ensuring construction efficiency, structural safety, and minimized material waste.

Sunmay’s high-quality seamless aluminum profiles are widely used across multiple industries, including:

Across these applications, Sunmay seamless aluminum profiles not only meet demands for high strength, durability, and aesthetics, but also provide reliable supply and customization options, helping trade clients, procurement agents, and contractors reduce project risks and improve efficiency.

Sunmay holds full export qualifications and an efficient logistics system, enabling reliable delivery of large orders worldwide. Each project receives detailed production planning and quality reports, ensuring profiles meet specifications. Partnerships with international shipping companies ensure fast customs clearance and safe transport, with customized packaging solutions for diverse markets including South America, Europe, Africa, and North America. Clients can expect timely and reliable delivery for large-scale projects.

Q1: What makes high-quality aluminum construction materials different from standard aluminum?

A: High-quality aluminum construction materials, such as seamless aluminum profiles, use premium alloy composition, advanced extrusion processes, and surface treatments like anodization. These ensure higher strength, corrosion resistance, dimensional precision, and long-term durability.

Q2: Are seamless aluminum profiles suitable for outdoor applications?

A: Yes. Profiles with anodized or powder-coated surfaces resist corrosion, UV exposure, and extreme weather, ideal for outdoor structures and industrial installations.

Q3: How do industrial aluminum extrusions improve project efficiency?

A: Industrial aluminum extrusions provide precise, lightweight, and strong components that reduce assembly time, minimize material waste, and enhance structural integrity, supporting faster construction and machinery installation.

Q4: Can aluminum profiles be customized for specific projects?

A: Absolutely. Manufacturers, including Sunmay, offer tailored extrusion profiles with specific cross-sections, lengths, and surface finishes to match project requirements, ensuring optimal performance.

Sunmay specializes in high-quality aluminum profile production with advanced extrusion lines, automated surface treatment equipment, and rigorous quality control systems. Our experienced engineering team oversees every step, from material sourcing to final product shipment, ensuring international standard compliance. The factory supports large-scale production and rapid response to custom orders, offering stable and reliable supply to global clients.

Sunmay provides comprehensive customization for aluminum profiles, including cross-section design, material selection, surface finishing, and length processing. Our technical team offers professional guidance from design validation to sample testing. With successful applications in construction, industrial machinery, and transportation, clients benefit from improved efficiency, reduced costs, and solutions tailored to specific project requirements.

Sunmay’s OEM/ODM process includes requirement communication, design confirmation, sample production, mass manufacturing, and quality inspection delivery. Each stage is managed by a dedicated project manager to ensure accurate information flow and efficient execution. Clients receive real-time updates and quality reports throughout the process, enabling swift adjustments and professional, reliable cooperation.

Q1: What is a seamless aluminum profile?

A: A seamless aluminum profile is produced via precision extrusion without weld seams, offering high strength and dimensional accuracy for industrial equipment, construction frames, and precision instruments.

Q2: What advantages do industrial aluminum extrusions offer?

A: Lightweight, strong, corrosion-resistant, and customizable, they reduce construction difficulty and material cost while enhancing structural safety and project efficiency.

Q3: What applications suit high-quality aluminum construction?

A: Suitable for building curtain walls, window and door frames, machinery supports, rail vehicles, and renewable energy structures, performing reliably even in harsh environments.

Q4: How does surface treatment improve performance?

A: Anodization or powder coating enhances corrosion resistance, wear resistance, and aesthetics, extending service life and reducing maintenance costs.

Q5: Does Sunmay offer customization?

A: Yes, including profile cross-section, length, surface finish, and material type, tailored to project requirements.

Q6: How are large projects delivered reliably?

A: Sunmay uses strict QC systems and batch management, combined with efficient logistics, ensuring timely, stable delivery of large orders.

Q7: How to choose the right aluminum profile specification?

A: Provide project drawings or requirements; Sunmay engineers recommend optimal profiles based on load, installation, and environment.

Q8: How is quality ensured during export?

A: Each batch undergoes thorough inspection with certified packing, meeting international standards and ensuring safe transit.

Q9: How to calculate cost-effectiveness?

A: By analyzing weight, strength, processing efficiency, and transport, high-performance profiles reduce material waste and improve project efficiency.

Q10: Why choose Sunmay as a long-term supplier?

A: With advanced equipment, strict QC, extensive customization experience, and global logistics, Sunmay offers reliable, consistent supply for procurement, trade, and engineering clients.

Tags :

Whatsapp : +8617366266559

Email : sales@sunmayalu.com

Tel : +86 -17366266559

Hi! Click one of our members below to chat on