High-quality ultra-thin aluminum profiles from SUNMAY, designed for durable, lightweight, and precise construction and architectural projects worldwide.

Material & Temper :

Aluminium Alloy 6063 T6Length :

3.6 metersApplication :

Bottom cover of electric vehicle battery packLead time :

10 to 30 daysExecutable Quality Standard :

According to customer agreement standardsSurface Treatment :

Mill FinishPackaging method :

According to customer agreement standardsCross Section Size :

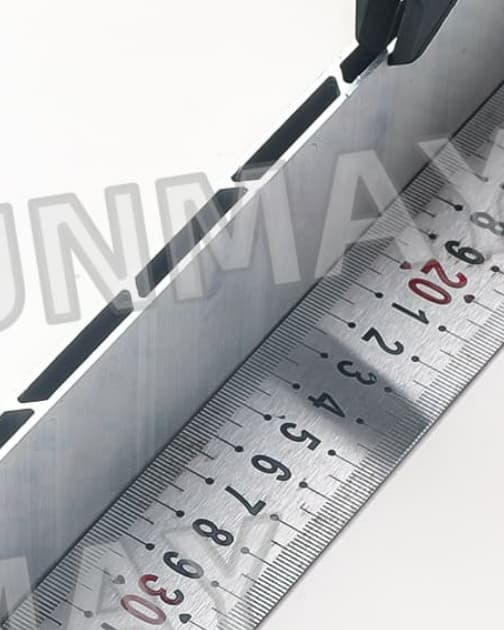

Width:450 millimeters; Wall Thickness:1.5 millimetersOur ultra-thin aluminum profiles are crafted from high-strength 6063-T5 aluminum alloy, utilizing advanced extrusion processes and precision mold designs. This ensures exceptional accuracy in thickness, width, and length. Each profile's cross-section is optimized for mechanical performance, offering superior load-bearing capacity while maintaining lightweight properties. Surface treatments include anodizing, electrophoresis, and powder coating, making precision aluminum extrusions highly resistant to corrosion and adaptable to various climates. The ultra-thin design meets aesthetic, architectural, and industrial requirements, facilitating easier transportation and installation while enhancing overall project efficiency.

| Feature/Advantage | Description | Customer Value |

|---|---|---|

| High-Precision Extrusion & Ultra-Thin Design | Thickness tolerance ±0.05mm, uniform cross-section | Easy installation; seamless connections for doors, windows, and facades |

| High-Strength 6063-T5 Aluminum Alloy | Excellent strength, durability, and corrosion resistance | Enhances structural safety and reduces maintenance frequency |

| Multiple Surface Treatments | Anodizing, electrophoresis, powder coating | Suitable for various environments; extends product lifespan |

| SUNMAY Advanced Manufacturing System | Precision molds and automated production lines | Consistent quality; efficient bulk delivery |

| Flexible Customization | Supports cross-section, length, and color customization | Meets diverse architectural and industrial project needs |

SUNMAY's ultra-thin aluminum profiles combine high strength with lightweight design, fulfilling modern construction, decoration, and industrial requirements for aesthetics, durability, and precision. Precision aluminum extrusions reduce installation errors and increase efficiency. Diverse surface treatments enhance corrosion resistance while offering various color and texture options, meeting different design styles. SUNMAY's manufacturing systems comply with international standards, ensuring SUNMAY aluminum systems perform reliably in global projects, helping clients reduce overall costs and improve construction quality.

| Customer Pain Point | SUNMAY Solution |

|---|---|

| Thin profiles lacking strength | 6063-T5 high-strength aluminum alloy with optimized cross-section ensures ultra-thin profiles retain load-bearing capacity |

| Surface oxidation or fading | Multiple surface treatments enhance durability in various climates |

| Deformation during transportation | Precision extrusion and automated production ensure straightness and stability |

| Complex customization requirements | Flexible customization service allows quick adjustment of cross-section, length, and color |

SUNMAY addresses common challenges with ultra-thin aluminum profiles, including thickness, strength, surface quality, and customization. Through precision extrusion and high-quality materials, profiles maintain stability while ultra-thin. Surface treatments ensure precision aluminum extrusions remain corrosion-free and fade-resistant worldwide. Flexible customization improves efficiency, reduces project risks, and ensures smooth installation.

SUNMAY maintains a mature supply chain and global export capability. From requirement communication, sample validation, to mass production and logistics, each step is strictly controlled. Collaborations with international shipping partners ensure SUNMAY aluminum systems reach South America, Europe, Africa, and North America efficiently and safely, supporting on-time project completion.

SUNMAY features advanced production equipment and comprehensive quality control, including precision mold machining, aluminum billet casting, extrusion, and various surface treatments. Our experienced R&D and technical teams support diverse project requirements, ensuring every ultra-thin aluminum profile and precision aluminum extrusion meets international engineering standards. Strict factory management guarantees straightness, cross-section precision, and surface quality for every product.

SUNMAY offers full-process customization from design to delivery, including cross-section, thickness, color, and surface treatment. Our technical team quickly develops samples and testing for projects, enabling seamless transition from small trial orders to mass production. Successful cases include commercial complex facades and industrial support structures in South America, with customized profiles meeting strict construction requirements.

The OEM/ODM process includes: requirement analysis and technical evaluation; design and mold development; sample production and validation; mass production and quality inspection; packaging and logistics; after-sales support. Each stage maintains efficient communication, ensuring SUNMAY aluminum systems are delivered according to client specifications and with high satisfaction.

Q1: Are SUNMAY ultra-thin aluminum profiles suitable for outdoor use?

A1: Yes, anodized and powder-coated profiles are designed for long-term outdoor use, resisting corrosion and fading under various climates.

Q2: What is the minimum order quantity?

A2: Standard MOQ is 500 kg, but small-batch trial production is flexible based on project requirements.

Q3: What color and surface finishes are available for customization?

A3: Options include RAL colors, wood grain transfers, matte or glossy finishes, suitable for architectural and interior design.

Q4: What is the typical production lead time?

A4: Standard profiles take 3-4 weeks; customized profiles take 5-6 weeks depending on complexity and quantity.

Q5: What global shipping methods are available?

A5: Sea freight, air freight, and multimodal transport are available to ensure precision aluminum extrusions arrive safely worldwide.

Q6: Does SUNMAY provide technical support?

A6: Yes, full technical support from design, installation to after-sales is provided to ensure smooth project execution

Tags :

Whatsapp : +8617366266559

Email : sales@sunmayalu.com

Tel : +86 -17366266559

Hi! Click one of our members below to chat on