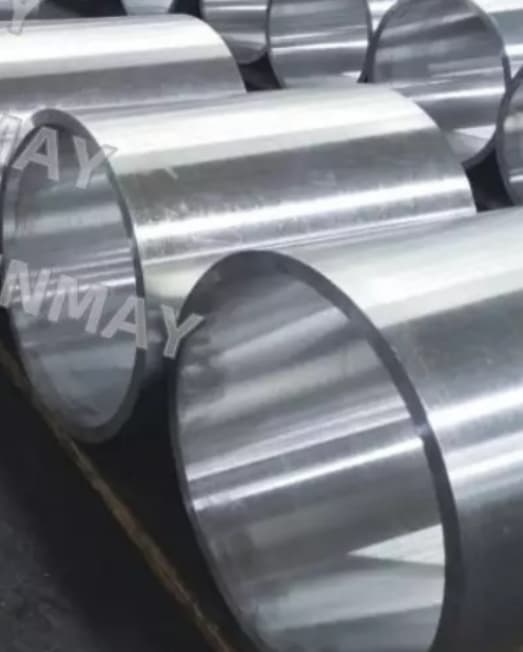

High-strength 5A06O aluminum tube with large diameter, ideal for construction, machinery, and industrial projects, offering excellent corrosion resistance and durability.

Material & Temper :

Aluminium Alloy 5A06OLead time :

10 to 30 daysExecutable Quality Standard :

According to customer agreement standardsPackaging method :

According to customer agreement standardsSpecifications :

Φ388mm*Ф356mm*470mmSunmay's 5A06O aluminum tube is manufactured using high-strength aerospace-grade aluminum alloy, providing excellent corrosion resistance, oxidation protection, and long-term structural stability. Each tube is precision-extruded to ensure consistent dimensions and smooth surface finish, suitable for construction, machinery, and various industrial applications. The large diameter aluminum pipe design balances weight and strength, facilitating transport and installation while maintaining safety and durability.

Every piece of industrial aluminum tubing undergoes rigorous quality control, including hardness testing, tensile strength, and surface uniformity inspections to meet international standards and customer-specific requirements. Tubes are available in multiple lengths, wall thicknesses, and surface treatments such as anodizing and powder coating, offering reliable and aesthetic solutions for industrial projects.

| Feature | Advantage | Customer Value |

|---|---|---|

| High-strength 5A06O aluminum alloy | Provides excellent durability and structural stability | Reduces replacement frequency and long-term costs |

| Large diameter design | Facilitates transport and installation | Improves construction efficiency and shortens project timelines |

| Precision extrusion process | Ensures consistent dimensions and smooth surface | Supports modular installation and minimizes on-site adjustments |

| Various surface treatments | Anodized, powder-coated, or custom colors | Enhances aesthetics and corrosion resistance for diverse environments |

By using 5A06O aluminum tube and large diameter aluminum pipe, Sunmay addresses critical quality, cost, and supply chain challenges while ensuring long-term industrial project stability.

| Pain Point | Sunmay Solution |

|---|---|

| Material corrosion | High-performance 5A06O alloy with anodizing or powder coating |

| High transportation and installation costs | Lightweight large-diameter design reduces logistics and labor expenses |

| Inaccurate dimensions | Precision extrusion ensures stable tube dimensions for easy installation |

| Long lead time | Optimized production scheduling and inventory management for fast delivery |

For example, in coastal South American projects, industrial aluminum tubing resists salt corrosion and reduces handling costs, meeting high-strength industrial requirements.

Sunmay has extensive experience handling large-scale projects with orders of hundreds of tons. Projects in South America, Europe, and Africa use Sunmay industrial aluminum tubing to ensure timely delivery. The company holds complete export qualifications, including ISO certification, certificate of origin, and quality inspection reports, ensuring smooth customs clearance. The global logistics system includes professional packaging and transportation solutions to minimize handling damage and risk. For multi-country projects, Sunmay provides staged delivery and on-site technical support, allowing construction teams to install and use tubes efficiently.

Sunmay’s factory is equipped with advanced extrusion machines, automated cutting, and surface treatment lines, producing tens of thousands of tons annually. Quality control covers raw material inspection, online extrusion monitoring, coating uniformity tests, and final inspections before shipment. The engineering team includes experienced engineers, process specialists, and project managers, providing one-stop solutions from product design to on-site support. Continuous R&D improves corrosion resistance and mechanical strength, ensuring tubes meet industrial demands across South America, Europe, and Africa.

Sunmay offers full customization of diameter, wall thickness, length, surface treatment, and color. Coastal industrial projects may use dual protection (anodized + powder coating) for extended lifespan, while high-end commercial projects in Europe and North America can choose RAL custom colors for functionality and aesthetics. Sunmay provides rapid response: design proposals and quotes are delivered within 48 hours, and samples are available within 7–10 days. Strict quality tracking ensures each batch meets client-specific requirements. Customers can choose standard or fully customized specifications for complex project needs.

Q1: What is a 5A06O aluminum tube used for?

A1: It is widely applied in construction, machinery, energy pipelines, and industrial facilities due to its strength, corrosion resistance, and lightweight design.

Q2: Is large diameter aluminum pipe durable for industrial applications?

A2: Yes, the combination of 5A06O aluminum alloy and precision extrusion ensures structural integrity under harsh conditions.

Q3: Can Sunmay provide custom sizes and finishes?

A3: Absolutely. Options include various lengths, diameters, wall thicknesses, anodized and powder coating finishes.

Q4: How long can industrial aluminum tubing last outdoors?

A4: Properly treated tubes can last decades in coastal, humid, or high-UV environments.

Q1: Why choose Sunmay 5A06O aluminum tube?

A1: Sunmay uses high-strength 5A06O aluminum alloy with precise extrusion and surface treatments for durability and corrosion resistance.

Q2: Are custom diameters available?

A2: Yes, all tubes can be customized in diameter, wall thickness, length, and surface finish according to project requirements.

Q3: What is the lead time for large orders?

A3: Efficient production planning and inventory management ensure timely delivery worldwide.

Q4: Are tubes suitable for harsh environments?

A4: Yes, anodized and powder-coated tubes withstand corrosion, UV exposure, and humidity.

Q5: How does lightweight aluminum tubing benefit construction?

A5: Reduces labor and transport costs, improves installation speed, and maintains structural strength.

Whatsapp : +8617366266559

Email : sales@sunmayalu.com

Tel : +86 -17366266559

Hi! Click one of our members below to chat on