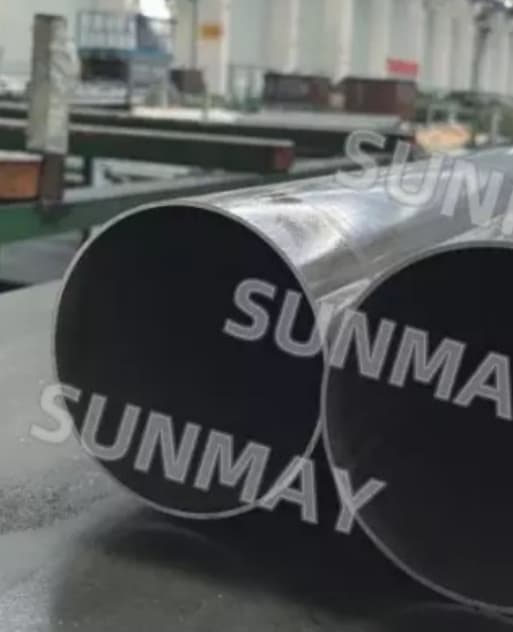

Premium 2A12 T4 aluminium thin-walled tube, engineered for high-precision applications in construction, industrial projects, and structural frameworks.

Material & Temper :

Aluminium Alloy 2A12 T4Lead time :

10 to 30 daysExecutable Quality Standard :

According to customer agreement standardsPackaging method :

According to customer agreement standardsSpecifications :

Φ127mm*2.0mm*2900mmSunmay's 2A12 T4 aluminium tube is crafted from high-strength aluminium alloy combined with advanced heat treatment technology, ensuring exceptional strength and toughness while maintaining lightweight characteristics. Its thin-walled design balances precision and weight, making it ideal for industrial structures, construction frameworks, and precision machinery applications. The tubes undergo precise extrusion and directional annealing processes, achieving micrometer-level dimensional stability and smooth surfaces that minimize wear in subsequent machining, fully meeting international engineering standards and customer-specific requirements.

Structurally, the aluminium alloy thin-walled tube features optimized wall thickness distribution and cross-section design, ensuring the best balance between load-bearing capacity and bending resistance. Anodized surface treatment enhances corrosion resistance, extending service life in humid, marine, and industrial environments while reducing maintenance costs. These design considerations allow Sunmay products to meet the stringent demands of construction companies, engineering contractors, and precision industrial clients.

| Feature | Advantage | Customer Value |

|---|---|---|

| Material: 2A12 T4 Aluminium Alloy | High strength, lightweight | Enhances structural load capacity and reduces transportation costs |

| Thin-Walled Design | Precision and lightweight | Reduces production costs while maintaining stable performance |

| High-Precision Extrusion | Dimensional accuracy and controlled tolerances | Ensures precise assembly in machinery and industrial applications, minimizing rework |

| Anodized Surface | Corrosion and wear-resistant | Extends service life and reduces long-term maintenance costs |

| International Standard Testing | ASTM / EN compliance | Meets export and large-scale project requirements |

The high precision of the high-precision aluminium tube enhances quality in construction frameworks and industrial machinery. In construction, thin-walled tubes reduce structural weight while ensuring safety. In machinery, precise aluminium tubes maintain assembly accuracy, reducing waste and improving production efficiency. Anodized surfaces enhance corrosion resistance, minimizing long-term maintenance and providing cost-effective solutions for clients.

| Pain Point | Solution |

|---|---|

| Tubes prone to deformation or unstable dimensions | Use 2A12 T4 high-strength alloy with precise extrusion to ensure micrometer-level dimensional stability |

| Thin-walled tubes vulnerable during transport or installation | Optimized wall thickness and surface reinforcement enhance bending and impact resistance |

| Long supply chain and delayed delivery | Sunmay's robust production and logistics system ensures timely batch supply |

| Project compliance with international standards | Products tested to ASTM and EN standards, suitable for export and large projects |

| High long-term maintenance costs | Anodized surfaces improve corrosion resistance, reducing maintenance frequency |

Sunmay addresses common industry challenges, such as tube deformation, durability, and supply instability, by selecting premium materials, optimizing manufacturing processes, and implementing strict quality control. This ensures that 2A12 T4 aluminium tubes maintain precision, reliability, and long-term performance. Efficient inventory and logistics support on-demand delivery, mitigating supply chain risks and enhancing operational efficiency for construction and industrial applications.

Construction Frameworks: In high-rise buildings, industrial facilities, and bridges, aluminium alloy thin-walled tube serves as load-bearing frameworks or secondary beams. Lightweight design reduces structural load, while thin-wall precision ensures installation accuracy and structural safety. Anodized surfaces improve durability for long-term outdoor use.

Precision Machinery: Used in automation lines, robotic arms, and industrial equipment, high-precision aluminium tube guarantees part assembly accuracy, reduces tolerance errors, and enhances production efficiency. Thin-wall design minimizes overall equipment weight, improving operational flexibility and stability.

Transportation: 2A12 T4 aluminium tube is applied in lightweight vehicles, railcars, and ship structures. High strength and corrosion resistance enhance safety and reduce energy consumption. Thin-walled design contributes to weight reduction, supporting modern transportation demands for energy efficiency and sustainability.

Industrial Pipelines and Structures: In gas and hydraulic pipelines and support frameworks, precise aluminium tubes improve pressure resistance and corrosion durability. Wall thickness uniformity ensures reduced leakage and deformation risks over long-term operations.

Sports and Outdoor Facilities: Tubes are used in sports equipment frames, tent trusses, and outdoor installations. Lightweight and strong, they are easy to transport and install while ensuring safety and longevity.

Sunmay offers a complete project delivery system, from raw material sourcing, precision extrusion, heat treatment, surface finishing, to final packaging and logistics. Every batch of 2A12 T4 aluminium tube is strictly controlled to meet client requirements. With international export certification and experience in global shipping standards, including sea, air, and land transport, Sunmay ensures timely bulk delivery to South America, Europe, Africa, and North America, supporting large-scale engineering projects efficiently.

Q1: What is 2A12 T4 aluminium tube used for?

A: 2A12 T4 aluminium tube is widely used in construction, industrial machinery, transportation, and structural applications due to its high strength, lightweight, and corrosion resistance.

Q2: How strong is a 2A12 T4 aluminium tube?

A: It features high tensile strength and good toughness, making it suitable for load-bearing applications while maintaining a thin-wall, lightweight structure.

Q3: Can 2A12 T4 aluminium tubes be customized?

A: Yes, tubes can be customized for diameter, wall thickness, length, and surface treatment to meet project-specific requirements.

Q4: Is 2A12 T4 aluminium tube suitable for outdoor use?

A: Yes, with anodized surface treatment, it provides excellent corrosion resistance, making it ideal for outdoor and marine environments.

Q5: How precise are high-precision aluminium tubes?

A: High-precision aluminium tubes from Sunmay achieve micrometer-level dimensional stability, ensuring reliable performance in industrial and construction applications.

Sunmay operates a modern aluminium extrusion facility equipped with high-precision automated extrusion lines, advanced heat treatment, and surface finishing systems. The factory maintains strict quality control throughout production, including raw material inspection, in-process dimensional checks, mechanical testing, and final inspection. Professional R&D and technical teams provide product optimization advice, ensuring each high-precision aluminium tube meets international standards. Sunmay's experience in handling large projects ensures stable product performance, reliable delivery, and quality assurance for all clients.

Sunmay provides highly flexible customization services for diameter, wall thickness, length, and surface treatment. Technical support includes design evaluation, process optimization, and sample verification. Successful projects span construction frameworks, machinery, and transportation applications. Rapid response and professional support allow clients to receive tailored solutions. 2A12 T4 aluminium tube customization offers significant advantages in performance, cost, and supply chain efficiency.

Sunmay's OEM/ODM process includes initial communication, design confirmation, sample production, mass production, quality inspection, and logistics delivery. Dedicated project managers ensure efficient communication at every stage. Technical teams provide guidance on manufacturing and surface treatment to guarantee compliance with client requirements and industry standards. The transparent and efficient process ensures clients receive high-quality products and professional service throughout the cooperation.

Q1: What industries commonly use 2A12 T4 aluminium tubes?

A: Industries including construction, industrial machinery, transportation, and infrastructure rely on 2A12 T4 aluminium tubes for their high strength, light weight, and durability.

Q2: How does a high-precision aluminium tube differ from a standard aluminium tube?

A: High-precision aluminium tubes maintain micrometer-level dimensional accuracy, ensuring consistent performance for mechanical assembly, structural applications, and industrial equipment.

Q3: Can Sunmay provide custom wall thickness and diameter for aluminium tubes?

A: Yes, Sunmay supports full customization, including wall thickness, diameter, length, and surface finish to meet project-specific requirements.

Q4: Are Sunmay aluminium alloy thin-walled tubes corrosion resistant?

A: Absolutely. With anodized surface treatment, the tubes offer excellent resistance to corrosion, suitable for outdoor, marine, and industrial environments.

Q5: What quality certifications do Sunmay aluminium tubes have?

A: Sunmay aluminium tubes undergo rigorous testing according to international standards such as ASTM and EN, ensuring compliance for export and large-scale engineering projects.

Q6: How can 2A12 T4 aluminium tubes reduce construction or industrial costs?

A: Their lightweight and high-strength properties reduce material usage, minimize transportation costs, and lower installation and maintenance expenses over the product lifecycle.

Q7: What is the lead time for bulk orders of high-precision aluminium tubes?

A: Sunmay maintains an efficient production and logistics system, ensuring timely delivery for bulk orders while meeting international shipping standards.

Q8: Are Sunmay aluminium tubes suitable for structural and load-bearing applications?

A: Yes, 2A12 T4 aluminium tubes provide high tensile strength and rigidity, making them suitable for structural frameworks, industrial equipment, and transportation components.

Tags :

Whatsapp : +8617366266559

Email : sales@sunmayalu.com

Tel : +86 -17366266559

Hi! Click one of our members below to chat on