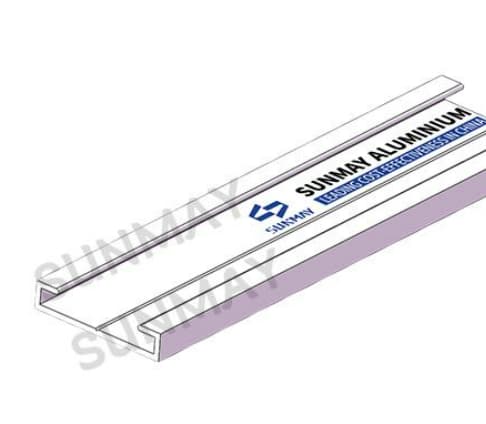

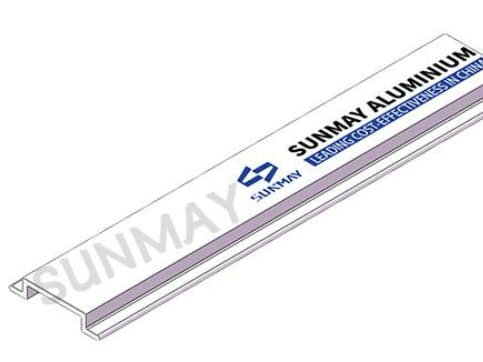

High-quality aluminum extrusion profiles ideal for doors, windows, and building projects, offering durability, precision, and long-term performance.

Material & Temper :

Aluminium Alloy 6063 T5Length :

5.98 MetersApplication :

Window and DoorLead time :

10 to 30 daysExecutable Quality Standard :

GB5237 Or per customer-specified quality standards.Surface Treatment :

Powder CoatedColor :

White Powder CoatingPackaging method :

Each aluminum profile is covered with decorative film and bundled with heat shrink wrap.Sunmay aluminum extrusion profiles are made from high-quality 6063-T5 aluminum alloy, combining excellent strength, toughness, and corrosion resistance to meet the demands of various construction and industrial environments. Using advanced extrusion technology, each profile maintains precise cross-section dimensions, ensuring perfect compatibility in doors, windows, curtain walls, and industrial equipment. The surface treatment of Sunmay construction aluminum profiles includes anodizing, enhancing corrosion resistance, wear resistance, and overall appearance, ensuring long-term stability in outdoor environments. For special projects, powder coating or wood grain finishing can also be provided to meet specific aesthetic and functional requirements. Sunmay durable aluminum profiles offer multiple section shapes and sizes to suit applications in door and window frames, curtain wall structures, equipment supports, and interior decoration. The combination of material strength and precision manufacturing ensures smooth construction, reduced rework, and increased project efficiency, fully meeting international building standards and industry regulations.

| Core Feature | Advantage | Customer Value |

|---|---|---|

| High-strength Aluminum | 6063-T5 alloy ensures excellent load-bearing capability | Enhances structural safety, reduces maintenance costs |

| Precision Extrusion Process | High mold accuracy with minimal cross-section deviation | Improves construction precision, reduces material waste |

| Anodized Surface Treatment | Corrosion-resistant, wear-resistant, aesthetically appealing | Extends service life, reduces maintenance expenses |

| Lightweight Design | Optimized cross-section structure | Facilitates transportation and installation, increases construction efficiency |

| Multiple Sizes Available | Accommodates various construction and industrial needs | Flexible project adaptation, improves supply chain responsiveness |

Sunmay durable aluminum profiles combine high-strength materials with precision manufacturing to deliver outstanding performance. The anodized or coated surfaces enhance corrosion resistance and aesthetic appeal, while lightweight and multi-size options provide flexibility, ease of installation, and cost savings. These profiles offer an optimal balance of quality, performance, and cost, ensuring seamless project execution.

| Customer Pain Point | Solution | Benefit |

|---|---|---|

| Profiles prone to deformation | Precision extrusion with high-strength aluminum | Ensures profile stability, reduces rework |

| Low installation efficiency | Lightweight design and standardized sizes | Speeds up construction, reduces labor costs |

| Insufficient corrosion resistance | Anodized or coated surfaces | Extends service life, reduces maintenance |

| Long supply lead times | Multiple size inventory and fast customization | Meets urgent project needs, improves responsiveness |

Construction and industrial projects often face challenges such as profile deformation, low installation efficiency, poor corrosion resistance, and long supply cycles. Sunmay construction aluminum profiles solve these issues with high-strength material, precision extrusion, lightweight and standardized design, and a range of surface treatment options. Fast inventory and custom solutions ensure timely delivery and stable supply, effectively addressing customer pain points.

1. Building Doors and Windows: Sunmay aluminum extrusion profiles are widely used in residential, commercial, and industrial door and window frames. High strength and precise dimensions ensure stability and sealing performance, while anodized surfaces maintain appearance and durability in outdoor environments.

2. Industrial Equipment Supports: For automation equipment, production lines, and machinery frames, construction aluminum profiles provide reliable support. Modular design facilitates quick installation and adjustments, while lightweight construction reduces overall weight and improves operational efficiency.

3. Curtain Wall Systems: Curtain walls require precise and durable profiles. Sunmay durable aluminum profiles provide reliable structural support, ensuring seamless component integration and long-term stability in various climates.

4. Transportation Infrastructure: Aluminum profiles are ideal for bus shelters, signage poles, and lightweight bridge structures. Corrosion resistance and optimized cross-sections reduce installation difficulty and maintenance costs.

5. Furniture and Interior Decoration: Sunmay profiles are used in cabinets, partitions, display racks, and decorative structures, combining aesthetic appeal and functionality for commercial and residential projects.

These applications demonstrate the versatility of Sunmay durable aluminum profiles, meeting high standards across construction, industrial, transportation, and furniture sectors, while improving efficiency and reducing long-term costs.

Sunmay maintains a comprehensive project delivery system, from order confirmation, design review, production scheduling, to packaging and logistics tracking. Certified for international export standards, Sunmay delivers high-volume orders to South America, Europe, Africa, and North America efficiently. Professional packaging and global logistics ensure secure, timely delivery for both samples and large-scale projects, providing customers with reliable supply chain support.

Customers seeking aluminum extrusion profiles focus on material strength, supply cycle, cost efficiency, and ease of installation. Sunmay offers standard sizes and flexible custom solutions to meet project needs while ensuring high quality and timely delivery. Surface treatment guarantees long-term outdoor performance, while lightweight design simplifies transport and installation. Comprehensive project support helps clients control costs, improve efficiency, and minimize risk.

Sunmay operates modern production workshops equipped with advanced extrusion machines and automated inspection systems. The technical team manages the entire process from material selection to finished products. Sunmay construction aluminum profiles undergo strict quality inspection at every stage to meet international construction and industrial standards. Extensive project experience and successful case studies worldwide demonstrate the brand's reliability in delivering high-performance aluminum profiles.

Sunmay provides full customization services, including profile design, length specifications, surface treatment, and packaging solutions. Close communication with clients ensures precise implementation from design review to sample approval and bulk production. With thousands of successful customized solutions, Sunmay can quickly respond to both small and large projects, delivering personalized, efficient services.

The OEM/ODM cooperation process includes requirement analysis, design confirmation, sample production, mass production, and logistics delivery. Sunmay offers design optimization guidance to balance performance, cost, and construction needs. Transparent communication and strict quality control at every stage ensure efficient, reliable collaboration for global clients while reducing procurement risks.

Q1: What are the advantages of Sunmay aluminum profiles?

A1: Sunmay uses 6063-T5 high-strength aluminum alloy, combining excellent strength, corrosion resistance, and manufacturability, meeting construction and industrial requirements for stability and long-term durability.

Q2: Are these profiles suitable for outdoor and humid environments?

A2: Anodized durable aluminum profiles perform excellently outdoors and in humid conditions, maintaining color, shape, and structural integrity over time.

Q3: Can Sunmay provide customized profile sections or lengths?

A3: Yes, Sunmay offers flexible customization, including section design, length, and surface treatment, for both sample orders and large-scale projects.

Q4: What is the typical delivery time?

A4: Standard profiles can be shipped quickly. Custom profiles depend on design complexity and order quantity. Sunmay ensures timely delivery aligned with project schedules.

Q5: How are products protected during transport?

A5: All profiles are carefully packaged with protective films, cartons, and reinforced wooden frames, ensuring safe delivery and easy handling.

Q6: What industries and applications are suitable?

A6: Sunmay aluminum extrusion profiles are widely used in building doors and windows, curtain walls, industrial supports, transportation infrastructure, and furniture, meeting rigorous industry standards.

Q7: How is supply chain stability ensured?

A7: With ample inventory, advanced logistics, and fast customization, Sunmay can handle urgent orders and large-scale project demands globally.

Whatsapp : +8617366266559

Email : sales@sunmayalu.com

Tel : +86 -17366266559

Hi! Click one of our members below to chat on