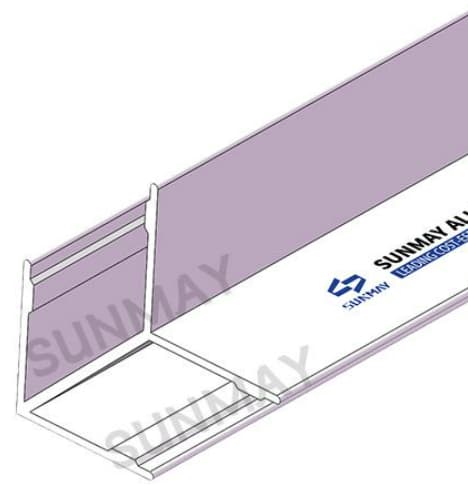

High-quality anodized aluminum profiles designed for strength and longevity, ideal for construction, industrial applications, and trade markets worldwide.

Material & Temper :

Aluminium Alloy 6063 T5Length :

5.98 MetersApplication :

Window and DoorLead time :

10 to 30 daysExecutable Quality Standard :

GB5237 Or per customer-specified quality standards.Surface Treatment :

Powder CoatedColor :

White Powder CoatingPackaging method :

Each aluminum profile is covered with decorative film and bundled with heat shrink wrap.Anodized aluminum extrusion profiles are high-performance industrial materials formed by extruding premium aluminum alloys, followed by advanced anodizing surface treatment to enhance durability and aesthetics. Our profiles are made from internationally recognized 6063-T5 aluminum alloy, known for its excellent mechanical properties such as high strength and superior machinability, making it suitable for diverse industrial applications. The extrusion process shapes the aluminum into complex cross-sectional profiles tailored to meet varied structural strength and design requirements. The anodizing treatment creates a hard, uniform oxide layer on the surface, significantly improving corrosion resistance and oxidation protection. This protective layer also enhances wear resistance and scratch durability, with hardness values reaching HV 300-400, far exceeding untreated aluminum surfaces.

Our anodized aluminum profiles come in customizable colors including silver, black, gold, and champagne, meeting the aesthetic and functional demands of architectural and industrial projects. This durable surface treatment also boosts weather resistance, ensuring long-term performance even in harsh environments. We employ precision molds and temperature-controlled extrusion processes to guarantee consistent dimensional accuracy and tight tolerances, complying with stringent industry standards. Each production batch undergoes rigorous mechanical and surface quality testing, maintaining a tensile strength between 180-250 MPa to fulfill structural safety requirements. Customized shapes and special surface finishes are also available, supporting diverse client specifications.

| Key Feature | Description | Advantage |

|---|---|---|

| Material Selection | High-quality 6063-T5 aluminum alloy with superior strength, machinability, and corrosion resistance. | Provides reliable mechanical performance, suitable for construction and industrial uses, ensuring structural safety. |

| Anodizing Treatment | Advanced anodizing forms a hard, dense oxide layer with customizable colors. | Greatly improves corrosion and wear resistance, delivering lasting surface beauty and extended product lifespan. |

| Precision Extrusion | Controlled temperature and pressure extrusion with high-precision molds ensures tight dimensional tolerances. | Ensures stable profile dimensions, facilitates complex assemblies, and reduces installation rework. |

| Customization | Offers various anodized colors (silver, black, gold, champagne) and complex profile designs. | Meets diverse client design needs, enhancing product competitiveness and brand image. |

| Mechanical Performance | Tensile strength ranges from 180 to 250 MPa; anodized layer hardness HV 300-400. | Guarantees structural strength and durability for demanding engineering applications. |

| Supply Chain Benefits | Supports mixed loading and flexible container arrangements with multiple port shipment options. | Reduces transportation costs, improves logistics efficiency, and quickly adapts to varied customer demands. |

Sunmay’s anodized aluminum extrusion profiles combine premium materials and state-of-the-art processing to meet the highest standards for durable aluminum profiles. Their excellent physical and aesthetic properties make them the preferred choice for builders and industrial users worldwide.

| Customer Issue | Sunmay Solution | Details |

|---|---|---|

| Inconsistent Product Quality | Use of premium 6063-T5 alloy combined with strict quality control and multiple inspection stages. | Ensures uniform high-quality across batches, minimizing customer concerns and risk. |

| Unstable Surface Color or Peeling | Automated anodizing lines with tight color tolerance and strong oxide film adhesion. | Delivers consistent, long-lasting anodized finish that meets design specifications. |

| Long Delivery Times | Ample raw material stock and efficient scheduling; supports mixed container shipments. | Shortens lead times, meeting urgent project and bulk order demands. |

| High Procurement Costs | Optimized supply chain and container consolidation reduce logistics expenses. | Allows clients to save on overall purchase and shipping costs through bulk procurement. |

| Complex Custom Specifications | Expert technical team supports custom profiles and color variants ensuring high precision. | Fulfills special design and structural requirements, increasing application versatility. |

Sunmay’s comprehensive approach effectively addresses key anodized aluminum extrusion profiles buyer concerns around quality, cost, lead time, and customization, ensuring smooth procurement and successful project execution.

Anodized aluminum profiles are widely favored in modern architectural elements such as door and window frames, curtain walls, railings, and shading systems. Their light weight and high strength reduce structural loads while ensuring safety. The corrosion resistance and attractive finishes meet the varied climatic demands in South America, Europe, and other regions.

These profiles are extensively used in manufacturing machinery frameworks, automated production lines, and instrument enclosures. The anodized surface extends equipment lifespan by resisting wear and easing maintenance, thus enhancing factory productivity and product quality.

In automotive, rail, and marine industries, durable aluminum profiles contribute to vehicle lightweighting, improving fuel efficiency. Their corrosion and weather resistance ensure long service life even under harsh conditions, ensuring safety and performance.

Sunmay’s anodized profiles serve as ideal materials for electronic device casings, heat sinks, and connectors, combining excellent mechanical strength with sleek surface finishes to meet the high standards of modern electronics manufacturing.

Sunmay’s robust production planning and supply chain management enable us to fulfill large-volume orders consistently. We support flexible mixed loading to maximize container utilization, significantly lowering freight costs. Multiple port shipment options allow efficient, secure delivery worldwide, ensuring uninterrupted supply for major projects. Our logistics solutions combine rich export experience and diverse transport methods to guarantee on-time delivery and seamless project continuity, earning trust from many large-scale engineering clients.

As a leading supplier in the aluminum extrusion industry, Sunmay rigorously follows international quality standards. All products are certified with CE, RoHS, and REACH, meeting global environmental and safety regulations for export. Our stable raw material sources and strict quality assurance systems provide clients with consistently high-quality anodized aluminum extrusion profiles that enhance market competitiveness. Sunmay excels in customization, precisely fulfilling diverse client requirements for dimensions, colors, and performance. Equipped with advanced inspection equipment and a skilled technical team, we ensure every order meets delivery timelines and quality standards, delivering reliable products customers can trust.

This transparent and efficient process guarantees smooth cooperation and mutual success.

Sunmay’s anodized aluminum extrusion profiles combine cutting-edge manufacturing technologies, strict quality control, and outstanding customer service. Trusted by buyers and contractors across South America, Europe, Africa, and North America, our products help optimize supply chains, reduce costs, and boost project competitiveness. Contact Sunmay today for expert custom solutions and high-quality durable aluminum profiles that drive your business forward.

Whatsapp : +8617366266559

Email : sales@sunmayalu.com

Tel : +86 -17366266559

Hi! Click one of our members below to chat on