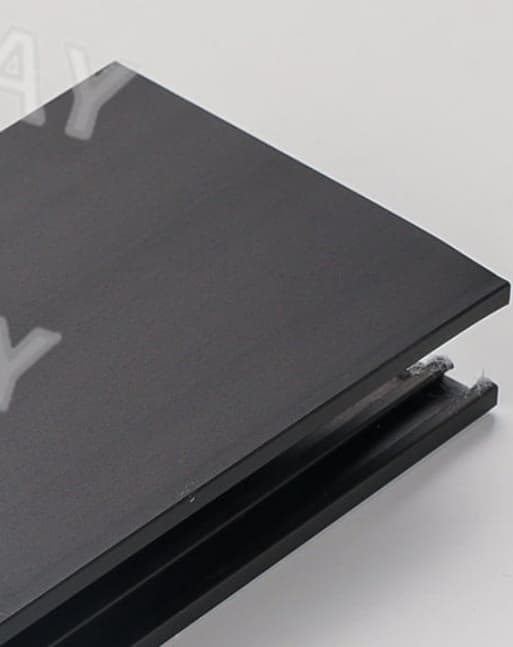

Durable black anodized aluminum extrusion profiles offer corrosion resistance, sleek finish, and versatile applications for construction, furniture, and industrial projects worldwide

Material & Temper :

Custom Aluminum Alloy with Heat TreatmentApplication :

Architectural, Decorative Home and Industrial Aluminum ProfilesLead time :

10 to 30 daysExecutable Quality Standard :

GB5237, TS16949, EN12020, EN755, EN573, Or according to customer agreement standardsSurface Treatment :

AnodizedColor :

BlackPackaging method :

Customized according to customer requirementsOur black anodized aluminum extrusion profiles are crafted from premium aluminum alloy using precision extrusion processes. The surface undergoes anodization, forming a protective layer that is resistant to corrosion and wear. This treatment not only provides a sleek and modern appearance but also effectively prevents oxidation, ensuring long-lasting durability.

The profiles are designed with optimal structural strength while remaining lightweight, making them easy to transport and install. Multiple cross-section shapes and sizes are available, suitable for building facades, interior decoration, furniture frameworks, and industrial components. The surface is smooth, uniform, and free from scratches or bubbles, meeting international standards for high-quality aluminum extrusion profiles.

| Feature | Description | Customer Value |

|---|---|---|

| Corrosion Resistance | Premium alloy with black anodized finish | Extends service life, reduces maintenance costs |

| High Strength & Lightweight | Precision extrusion ensures strength-to-weight balance | Reduces transportation costs and simplifies installation |

| Precision Dimensions | Tight tolerance control ±0.1mm | Meets engineering standards, minimizes secondary processing |

| Aesthetic Surface | Uniform black anodized layer with fine gloss | Enhances appearance value of buildings or products |

These advantages not only enhance physical performance but also provide solutions for quality, cost, and supply chain management. The corrosion resistance of black anodized aluminum minimizes replacement costs, while the lightweight aluminum extrusion profiles reduce transport expenses. Precision dimensions ensure efficient installation, and the high-quality surface meets global aesthetic and functional standards.

| Common Issue | Solution |

|---|---|

| Surface scratches | Protective film packaging minimizes transport damage |

| Inconsistent dimensions | Strict manufacturing process ensures ±0.1mm tolerance |

| Insufficient corrosion resistance | Black anodized finish enhances durability |

| Long delivery time | Efficient inventory management and production shorten lead time |

We provide comprehensive solutions for common customer challenges. Protective films reduce scratches, precise tolerances lower installation errors, anodized surfaces enhance corrosion resistance, and efficient inventory and production ensure on-time delivery. These measures allow customers to manage projects more effectively while ensuring anodized aluminum for construction meets international standards.

The versatility and reliability of aluminum extrusion profiles meet global market requirements. From South America to Europe and Africa, black anodized aluminum profiles deliver consistent performance and elegant appearance.

With years of export experience, we handle large-scale construction and industrial projects. Comprehensive production planning, inventory management, and logistics systems ensure timely delivery. Full export certification supports smooth customs clearance, and we provide reliable supply chain support for both full container and partial shipments worldwide.

Sunmay features advanced extrusion and anodizing lines, equipped with automated inspection systems to ensure precise dimensions and surface quality. Our QC team oversees raw material inspection, production monitoring, and finished product testing. Each batch of black anodized aluminum and aluminum extrusion profiles meets international standards. The technical and management teams provide end-to-end solutions from design to delivery.

We offer customized solutions including cross-section shapes, dimensions, surface treatments, and packaging. For South American outdoor projects, European interior applications, and North American industrial uses, we provide rapid response and flexible production to deliver tailored products with high quality and consistency.

This workflow emphasizes professional service and efficient communication, ensuring reliable products and service for anodized aluminum for construction projects.

Q1: What are the benefits of black anodized aluminum?

A: Black anodized aluminum provides corrosion resistance, long-term durability, and a sleek finish suitable for construction, furniture, and industrial applications.

Q2: Can aluminum extrusion profiles be customized?

A: Yes, extrusion profiles can be tailored in shape, size, and surface finish to meet project-specific requirements.

Q3: How does anodized aluminum perform outdoors?

A: Anodized aluminum offers excellent weather resistance, preventing corrosion and maintaining color integrity under harsh environmental conditions.

Q1: What sizes are available for black anodized aluminum extrusion profiles?

A: We offer a wide range of standard and custom sizes for different project needs.

Q2: Is the surface finish durable?

A: Yes, the black anodized surface resists scratches, corrosion, and fading, ensuring long-lasting performance.

Q3: What industries use these profiles?

A: Applications include construction, furniture, industrial machinery, electronics, and outdoor installations.

Q4: Can Sunmay provide certificates for international projects?

A: Yes, we provide ISO, SGS, and other certifications to meet global quality standards.

Q5: How long is the delivery time?

A: Depending on order quantity, standard orders ship within 2–4 weeks, and large custom orders are coordinated for timely delivery.

Tags :

Whatsapp : +8617366266559

Email : sales@sunmayalu.com

Tel : +86 -17366266559

Hi! Click one of our members below to chat on