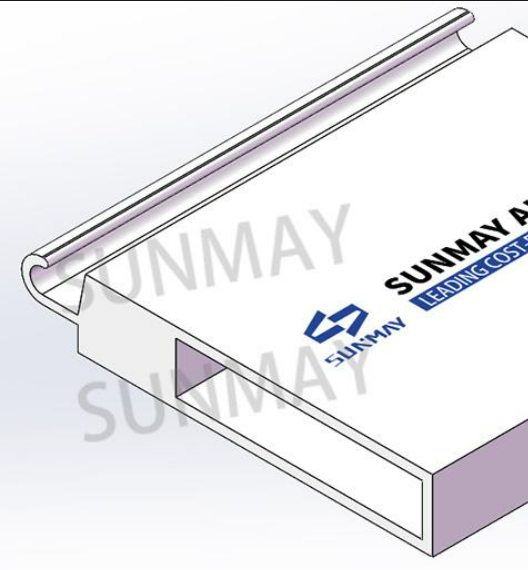

Discover high-quality, cost-effective aluminum alloy window frames designed for durability and energy efficiency. Ideal for residential and commercial buildings.

Material & Temper :

Aluminium Alloy 6063 T5Length :

5.97 metersApplication :

Window & DoorLead time :

10 to 30 daysExecutable Quality Standard :

GB5237 Or per customer-specified quality standards.Surface Treatment :

Anodizing, Powder Coating, Wooden GrainColor :

Matt Silver Anodized, Matt Champagne Anodized, Wooden GrainPackaging method :

Each aluminum profile is covered with decorative film and bundled with heat shrink wrap.

Aluminum alloy window frames are engineered to deliver an outstanding balance of mechanical strength, energy efficiency, and aesthetic versatility. Known for their excellent corrosion resistance and lightweight properties, these frames provide long-lasting performance in both residential and commercial settings. With a sleek, contemporary appearance and compatibility with double-glazed or thermal break systems, energy-efficient aluminum window frames are increasingly favored in modern architecture for their ability to enhance insulation, reduce energy loss, and support sustainable building design.

| Specification | Details | Description |

|---|---|---|

| Materials | 6063‑T5 / 6061 Alloy | High corrosion resistance; GB/T 3190 compliant. |

| Surface Finish | Anodized / Powder‑Coated | Enhances durability & style. |

| Color Options | Matte Black / Silver Grey / White | Custom RAL or Pantone shades available. |

| Wind Load | High‑pressure rated | Withstands severe weather. |

| Thermal Conductivity | Low | Boosts building insulation. |

| Custom Sizes | On request | Fits diverse architectural needs. |

| Salt‑Spray Test | >1000 h | Ideal for marine or industrial zones. |

1. Outstanding Cost Performance: High‑grade alloy and automated fabrication keep prices competitive without sacrificing quality.

2. Long‑Term Durability: Anodizing and powder coating protect against corrosion, fading, and impact.

3. Energy Savings: Low thermal conductivity cuts HVAC expenses, perfect for energy‑efficient aluminum windows.

4. Design Flexibility: Wide color palette and customizable aluminum window frame dimensions match any façade style.

5. Minimal Maintenance: Robust finish means less cleaning, fewer repairs, and lower lifetime costs.

| Pain Point | Traditional Frames | Our Solution |

|---|---|---|

| Poor longevity | Fast corrosion & deformation | All‑weather alloy resists rust & warping. |

| High energy bills | Weak insulation | Thermally broken profiles slash heat loss. |

| Frequent upkeep | Repainting & repairs | Hard‑wearing finish needs minimal care. |

| Limited styling | Few colors / sizes | Full RAL range and made‑to‑measure options. |

• Residential: Modern homes gain curb appeal and lower utility costs.

• Commercial: Offices, malls, and hotels benefit from high wind resistance and sleek façades.

• Public Infrastructure: Airports, hospitals, and schools choose our frames for safety and longevity.

• Green Buildings: Essential for LEED‑focused projects demanding superior thermal performance.

At Sunmay, we are committed to delivering excellence in aluminum profile manufacturing through a combination of advanced production technologies and a strong emphasis on quality control. Our factory is equipped with modern extrusion lines and precision surface treatment facilities, enabling us to offer consistent product quality across large-scale orders and custom requirements. We operate under a comprehensive ISO 9001-certified quality management system, ensuring that each production stage—from raw material inspection to final packaging—meets rigorous international standards. Our aluminum products comply with CE certification for safety and structural reliability, making them suitable for global markets.

To support sustainable development, we have adopted RoHS and REACH-compliant materials and processes, reducing environmental impact without compromising performance. Our team also invests continuously in R&D, focusing on thermal insulation, corrosion resistance, and architectural aesthetics, helping clients stay ahead in competitive markets. With a reputation for strict quality control, short lead times, and responsive communication, Sunmay has established long-term partnerships with distributors, developers, and construction firms across Europe, North America, and Southeast Asia. Whether for standard profiles or customized extrusion projects, we provide reliable solutions backed by certifications, technical support, and stable supply chains.

Tags :

Whatsapp : +8617366266559

Email : sales@sunmayalu.com

Tel : +86 -17366266559

Hi! Click one of our members below to chat on