High-quality aluminum alloy door frame offering durability, sleek design, and cost efficiency, ideal for residential and commercial projects.

Material & Temper :

Aluminium Alloy 6063 T5Length :

5.97 metersApplication :

Window & DoorLead time :

10 to 30 daysExecutable Quality Standard :

GB5237 Or per customer-specified quality standards.Surface Treatment :

Anodizing, Powder Coating, Wooden GrainColor :

Matt Silver Anodized, Matt Champagne Anodized, Wooden GrainPackaging method :

Each aluminum profile is covered with decorative film and bundled with heat shrink wrap.In any door system, the frame anchors the leaf to the wall, defining installation stability, safety, and service life. Sunmay’s aluminum alloy door frame uses 6063-T5 alloy noted for high strength, toughness, and corrosion resistance. Compared with steel frames, it is lighter for easier transport and faster site work, and it will not rust—substantially cutting maintenance over time.

Material advantages. The 6063-T5 composition is precisely controlled and extruded at high temperature to balance mechanical strength with ductility. After anodizing, a dense oxide layer improves weatherability and provides excellent paint adhesion for powder coating or electrophoresis. This means a durable aluminum door frame keeps its profile accuracy and sheen in humid coastal climates of South America and in high-insolation, wide-temperature regions of Africa alike.

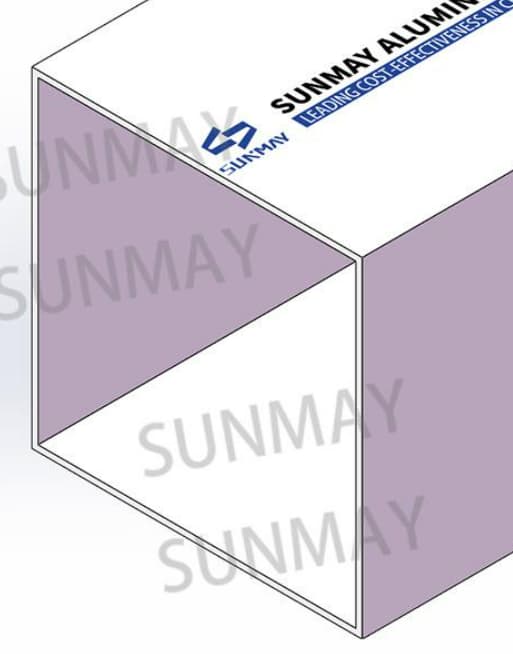

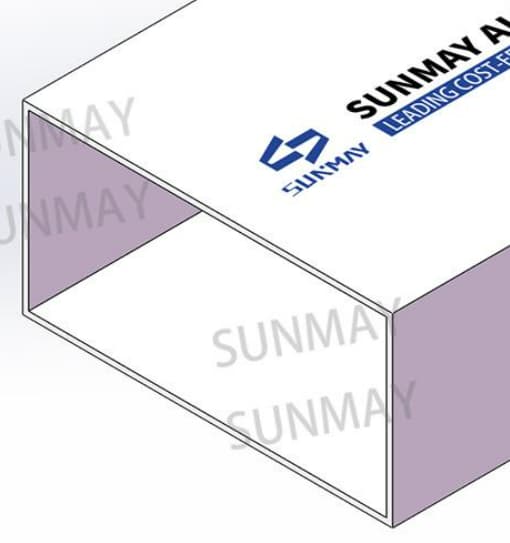

Structural design. Multi-cavity geometry with internal ribs boosts load capacity while improving thermal and acoustic performance. Standardized grooves and fixing points comply with international door & window norms, ensuring compatibility with multiple door systems and reducing on-site cutting and shimming.

Finishes & appearance. Options include anodizing, powder coating, and wood-grain transfer in a wide palette—from classic silver and champagne to deep coffee and matte black—so a cost-effective door frame can align perfectly with modern minimalist or traditional décor.

Standards & testing. Designs follow EN/ASTM benchmarks and undergo corrosion, load, wind pressure, and thermal-transfer tests. This engineering rigor shortens compliance cycles for export acceptance and reduces project risk.

| Core Feature | Benefit |

|---|---|

| High-strength aluminum alloy | Long-term dimensional stability and impact resistance |

| Multi-cavity profile design | Improved thermal/acoustic performance and overall durability |

| Diverse finishes | Seamless aesthetic fit across markets and building styles |

| High cost-performance | Lower purchase and lifecycle maintenance costs |

| International compliance | Smoother export documentation and project acceptance |

Choosing a truly cost-effective door frame is never about unit price alone—it’s the balance of performance, installation efficiency, and lifecycle economics. Sunmay’s frames start with high-strength alloy for structural reliability in high-traffic public buildings, while the multi-cavity cross-section elevates sound and thermal control for energy-aware projects. Diverse surface treatments meet regional preferences (e.g., deeper matte tones in Europe; warm metallic finishes in South America) without compromising coating adhesion or colorfastness. Cost efficiency comes from scaled extrusion, optimized material yields, and disciplined supply-chain controls—never from quality shortcuts. For contractors and fabricators, that translates to fewer callbacks, predictable schedules, and stronger end-user satisfaction.

| Pain Point | Solution |

|---|---|

| Corrosion in humid/coastal sites | High-resistance alloy + anodizing to extend service life |

| Tight schedules & on-site rework | Precision profiles/holes reduce cutting and adjustment time |

| Frequent maintenance & callbacks | Stable structure and finishes that resist wear and scratching |

| Export compliance complexity | EN/ASTM alignment with full test dossiers and certificates |

Across markets, teams struggle with climate durability, installation speed, and long-term upkeep. In Brazilian coastal projects, steel frames often show rust within 2–3 years; our aluminum alloy door frame with anodized finish resists salt spray for a decade or more. In large builds where every hour counts, standardized geometry limits on-site trim work, accelerating close-out. And for exports, Sunmay ships complete test reports and required certificates upfront, reducing clearance risk and admin overhead. These pragmatic fixes cut total cost without compromising a durable aluminum door frame’s performance.

Architects in South America, Europe, and the Middle East increasingly specify a durable aluminum door frame to replace wood or steel. Modern lines, stable geometry, and customizable finishes deliver a refined interior look for sliding glass doors and main entrances. Humidity resistance prevents warping or cracking—especially valuable in coastal cities.

Commercial assets demand low upkeep and high reliability. A cost-effective door frame engineered for repeated daily cycles pairs with abrasion-resistant coatings to minimize visible wear. Improved acoustic behavior elevates workplace comfort for office tenants and co-working floors.

Environments with dust, impacts, and temperature swings call for stronger sections and robust coatings. Sunmay’s aluminum alloy door frame uses rib-reinforced cavities that help absorb knocks from trolleys or forklifts, maintaining alignment and function over long operating hours.

Schools, hospitals, airports, and stations require frames that are cleanable, safe, and resilient. Aluminum surfaces don’t harbor mold and can be sanitized quickly. Under emergency loads, structural stability aids safer egress—an important risk-mitigation layer.

From tropical monsoons to sub-zero winters, profile accuracy and thermal stability prevent door binding from expansion/contraction. For cross-border contractors, a durable aluminum door frame reduces after-sales claims and rework risk across varied climates.

Sunmay’s delivery model supports engineering-led coordination from design confirmation through production scheduling, QC, export clearance, and international logistics. We lock technical parameters early, mark critical interfaces on drawings, and combine batch throughput with agile change handling. For export, we supply origin certificates, CE where required, and full test dossiers aligned to EN/ASTM, streamlining customs and acceptance. Long-term carriers and forwarders allow us to balance sea, air, or rail to meet site dates across South America, Europe, Africa, and North America—so your aluminum alloy door frame arrives on time and installation-ready.

Market pricing can vary by 30% or more. The right cost-effective door frame optimizes lifetime value—not just purchase price. Confirm the alloy pedigree (e.g., 6063-T5), inspect finish quality (uniform film, no bubbles or color drift), and check structural logic (multi-cavity with ribs). Finally, assess the supplier’s delivery discipline and after-sales support. A genuinely cost-effective solution performs across five axes—mechanical, aesthetic, installation, maintenance, and supply assurance.

Sunmay operates modern extrusion, finishing, and precision-machining lines with traceable, in-house workflows—from die design and aluminum extrusion to anodizing, powder coating, and fine cutting. Multiple QC gates verify raw materials, dimensional accuracy, coating adhesion, corrosion resistance, and mechanical performance. Our engineering team understands global building norms and responds quickly with practical optimizations to keep programs on schedule. This end-to-end control ensures consistency for every durable aluminum door frame that leaves the plant.

Projects differ in section geometry, wall thickness, colors, and fixing details. Sunmay supports full-cycle customization: concept refinement, section design, wall selection, slot layout, sampling, and mass production. Typical lead times enable sampling within days for fit-up verification and aesthetic approval. For complex developments, a tailored aluminum alloy door frame reduces site work and improves final alignment.

Whether OEM or ODM, the goal is predictable quality and punctuality for every cost-effective door frame shipment, supported by transparent communication and documented checkpoints.

Yes. Our aluminum alloy door frame uses corrosion-resistant alloy and durable finishes (anodizing or powder coat) to maintain appearance and structure in high humidity and salt-spray locations.

A cost-effective door frame balances performance and lifecycle cost. Scaled extrusion, precise machining, and robust finishes reduce rework and maintenance—so you spend less over the product’s life without sacrificing quality.

Absolutely. We customize dimensions, surface finishes, and interface slots so your durable aluminum door frame integrates cleanly with door leaves and architecture.

Yes. We align with EN/ASTM and provide test reports, CE (where applicable), and origin certificates to streamline customs and project acceptance.

No special tools are needed. Standard door & window tools work thanks to consistent geometry and precise hole placement, cutting install time and effort.

Each set is scratch-protected and moisture-wrapped to withstand sea, air, or rail freight so the durable aluminum door frame arrives site-ready.

Tags :

Whatsapp : +8617366266559

Email : sales@sunmayalu.com

Tel : +86 -17366266559

Hi! Click one of our members below to chat on