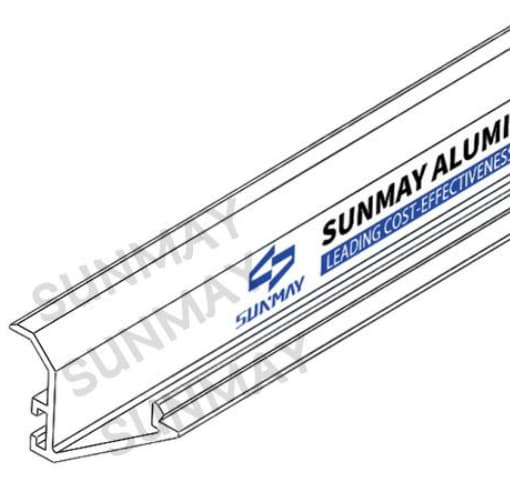

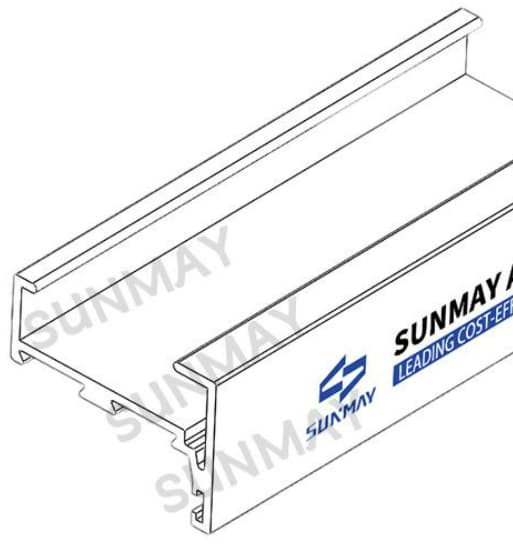

Durable aluminum alloy profiles with high strength and lightweight design, ideal for doors, windows, and structural projects in construction and industrial applications.

Material & Temper :

Aluminium Alloy 6063 T5Length :

6 metersApplication :

Window and DoorLead time :

10 to 30 daysExecutable Quality Standard :

GB5237 Or per customer-specified quality standards.Surface Treatment :

Anodizing, Powder Coating, Woode Grain TransferColor :

Matt Silver Anodizing 15μm, Black Anodizing 15μm, Powder Coating 80μm, Wooden Grain Transfer.Packaging method :

Each aluminum profile is covered with decorative film and bundled with heat shrink wrap.Sunmay's aluminum construction profiles are made from premium high-performance aluminum alloy, combining lightweight design with exceptional durability to withstand long-term use in construction and industrial applications. Advanced extrusion technology ensures uniform material distribution, precise dimensions, and superior bending and compression resistance. Sunmay offers a variety of cross-sectional designs suitable for window frames, door frames, curtain wall systems, and large-scale industrial structures.

The profiles undergo professional surface treatments, including anodizing, powder coating, or custom color finishes, enhancing corrosion resistance while maintaining aesthetic appeal for diverse projects. The precisely controlled coating thickness ensures long-lasting performance even in tropical, South American coastal, or high-temperature African environments.

Our high-performance aluminum alloy profiles are designed for ease of installation. Their lightweight nature significantly reduces transportation and labor costs. Each batch undergoes rigorous quality control, including tensile, bending, and dimensional testing, guaranteeing safe and reliable performance in large construction projects. Additionally, Sunmay can customize cross-sectional shapes and thicknesses to meet specific project requirements. Sunmay's production process also prioritizes environmental sustainability by adopting energy-saving methods without compromising precision and material stability. Over the years, Sunmay has supported projects in South America, Europe, and Africa, earning a reputation for reliability and long-term partnerships.

| Feature | Advantage | Customer Benefit |

|---|---|---|

| High-strength aluminum alloy | Strong load-bearing for large-span structures | Prevents structural deformation and ensures safety |

| Lightweight design | Easier transportation and installation | Reduces logistics and construction costs |

| Precision extrusion | Accurate dimensions and smooth surface | Minimizes on-site adjustments and increases efficiency |

| Versatile surface treatment | Anodized or powder-coated options | Meets various design aesthetics and corrosion resistance needs |

| Customizable cross-section | Flexible adjustments per project requirements | Supports unique architectural and industrial applications |

| Eco-friendly production | Energy-efficient manufacturing | Reduces cost and aligns with sustainability goals |

By using lightweight aluminum extrusion technology, Sunmay profiles maintain structural integrity while reducing overall weight. This design is particularly advantageous for remote construction projects in South America and Africa, lowering shipping costs and facilitating faster installation. The combination of precise extrusion and rigorous quality control ensures dimensional stability and long-term reliability. Versatile surface treatments improve corrosion resistance and aesthetic appeal, while customization allows clients to meet diverse project specifications. Eco-friendly manufacturing further enhances cost efficiency and sustainability.

| Common Issue | Sunmay Solution |

|---|---|

| Profiles easily deform | High-performance aluminum alloy and strict extrusion testing |

| Long delivery lead times | Large-scale production and inventory management for fast response |

| High transportation costs | Lightweight design and optimized packaging to reduce logistics expenses |

| Non-compliance with building codes | Profiles meet international standards and support custom specifications |

| Surface corrosion | Anodized or powder-coated finishes for enhanced durability |

| Complex installation | Precision profiles and custom designs reduce on-site labor |

Sunmay addresses key challenges clients face during procurement and construction. Our high-performance aluminum alloy profiles provide strength and stability, mitigating deformation issues. Lightweight design reduces shipping and installation costs, particularly for long-distance export projects. Quality assurance and customization ensure compliance with local regulations, preventing construction delays. Corrosion-resistant surfaces suit coastal, tropical, or wet climates. Precision design minimizes on-site adjustments, boosting construction efficiency.

Sunmay has extensive experience delivering aluminum construction profiles for large-scale residential, commercial, and industrial projects. Thousands of tons of profiles have been exported to South America, Europe, Africa, and North America. The company ensures timely delivery through containerized and truck shipments, offering full logistics tracking throughout transit. Sunmay holds comprehensive export certifications and international standards, including ISO 9001 and CE certification, meeting client requirements worldwide. Export documentation is provided to streamline cross-border procurement, minimizing trade risks. Optimized packaging and lightweight design protect profiles during long-distance transport, while flexible production schedules and shipment plans guarantee timely delivery for large orders.

Sunmay operates modern factories equipped with automated aluminum extrusion lines, precision cutting equipment, and advanced surface treatment facilities. The strict quality control system covers raw material inspection, production monitoring, and final product testing, ensuring every high-performance aluminum alloy profile meets international standards. The factory's annual output reaches tens of thousands of tons, accommodating both small custom orders and large export projects. Experienced engineering teams provide technical support, including cross-section design, strength calculation, and surface treatment consultation. Automated monitoring systems track production in real-time, minimizing errors and ensuring consistent quality. Sunmay emphasizes sustainable production, reducing energy consumption and waste, offering clients high-quality products and reliable long-term partnership.

Sunmay provides flexible customization services for various market and industry requirements, including cross-section design, thickness, surface treatment, and color options. South American residential markets prefer large-span windows, European commercial projects emphasize aesthetics and corrosion resistance, and African industrial projects prioritize lightweight and durable solutions. Sunmay quickly responds to order changes, delivering profiles compliant with local building codes and project specifications. Customization includes initial design, sample verification, mass production, and delivery support, ensuring timely project completion. Clients can choose anodized or powder-coated finishes to enhance durability and aesthetics. Customization is not limited to construction; it also applies to industrial equipment, transportation infrastructure, and public projects. Flexible production and rapid response ensure high-quality delivery even under urgent or complex requirements.

This process emphasizes professional service and efficient communication, combining standard procedures with flexible customization to provide reliable OEM/ODM collaboration worldwide.

Q1: What are aluminum construction profiles used for?

A1: They are widely used in doors, windows, curtain walls, structural frameworks, and industrial applications. Their high strength-to-weight ratio ensures durability and safety for various construction projects.

Q2: How durable is high-performance aluminum alloy?

A2: It provides excellent corrosion resistance, dimensional stability, and long-term mechanical strength, suitable for residential, commercial, and industrial buildings globally.

Q3: Can lightweight aluminum extrusion reduce construction costs?

A3: Yes. Lighter materials reduce transportation and installation expenses while maintaining structural integrity, shortening project timelines and lowering labor costs.

Q4: Are aluminum profiles customizable?

A4: Absolutely. Sunmay offers tailored extrusion shapes, thicknesses, and surface finishes to meet diverse project requirements and environmental standards.

Q5: How do Sunmay profiles perform in harsh environments?

A5: Anodized or powder-coated finishes resist corrosion, UV exposure, and humidity, making them ideal for coastal, tropical, or high-temperature regions.

Q1: What makes Sunmay aluminum construction profiles high-quality?

A1: Sunmay uses high-performance aluminum alloy and precise extrusion processes to ensure dimensional accuracy, high strength, and corrosion resistance, meeting international building standards.

Q2: Can I order custom sizes for my project?

A2: Yes, Sunmay offers fully customizable profiles including shape, thickness, and surface finish, ensuring compliance with local building codes and project designs.

Q3: How quickly can Sunmay deliver large orders?

A3: With large-scale production and inventory management, Sunmay efficiently fulfills bulk orders, reducing lead times for international projects.

Q4: Are Sunmay profiles suitable for outdoor use?

A4: Absolutely. Anodized and powder-coated finishes provide excellent resistance to corrosion and UV exposure, ideal for long-term outdoor applications.

Q5: Which markets does Sunmay export to?

A5: Sunmay exports to South America, Europe, Africa, North America, and other regions. Profiles have been used in residential, commercial, industrial, and public infrastructure projects.

Q6: How does lightweight aluminum extrusion benefit construction projects?

A6: Reduced weight lowers transportation and installation costs, accelerates construction timelines, and maintains structural performance, offering economic and operational advantages.

Q7: How does Sunmay ensure consistent quality?

A7: Every batch undergoes rigorous testing for tensile strength, bending resistance, and surface quality. Automated monitoring systems track production in real-time to minimize errors.

Q8: Can Sunmay handle complex design requirements?

A8: Yes, Sunmay supports complex cross-sections and custom finishes, enabling architects and engineers to achieve aesthetic and functional goals.

Tags :

Whatsapp : +8617366266559

Email : sales@sunmayalu.com

Tel : +86 -17366266559

Hi! Click one of our members below to chat on