In the building and industrial sectors, aluminum alloy profiles have become indispensable structural materials. Particularly for projects where cost control and durability are paramount, finding the right balance between price, performance, and delivery time is a common challenge. Sunmay’s cost-effective aluminum alloy profiles are designed to address these needs, providing stable and reliable solutions for bulk international procurement by construction companies, traders, and engineering contractors.

Our profiles are mainly crafted from construction-grade aluminum alloys such as 6063 and 6061, offering excellent corrosion resistance and machinability. These profiles are suitable for structural support, surface decoration, door and window systems, and more. Coupled with a variety of surface finishing options and color customizations, we meet diverse aesthetic and functional requirements across different regions and project specifications. With years of export experience, Sunmay has established a comprehensive quality control process and a robust cross-border supply system. Each stage—from raw material selection, production, to shipment—is tightly monitored to ensure consistent quality and timely delivery of every batch.

Material and Process: Ensuring Structural Strength and Aesthetic Consistency

Sunmay selects only A00-grade aluminum ingots with a purity of over 99.7%, guaranteeing extrusion profiles meet international building standards in strength, toughness, and forming stability. Our main product lines include:

- 6063-T5: Widely used in building curtain walls and window frames, known for strong surface adaptability.

- 6061-T6: Offers higher strength, suitable for industrial structures and heavy load-bearing projects.

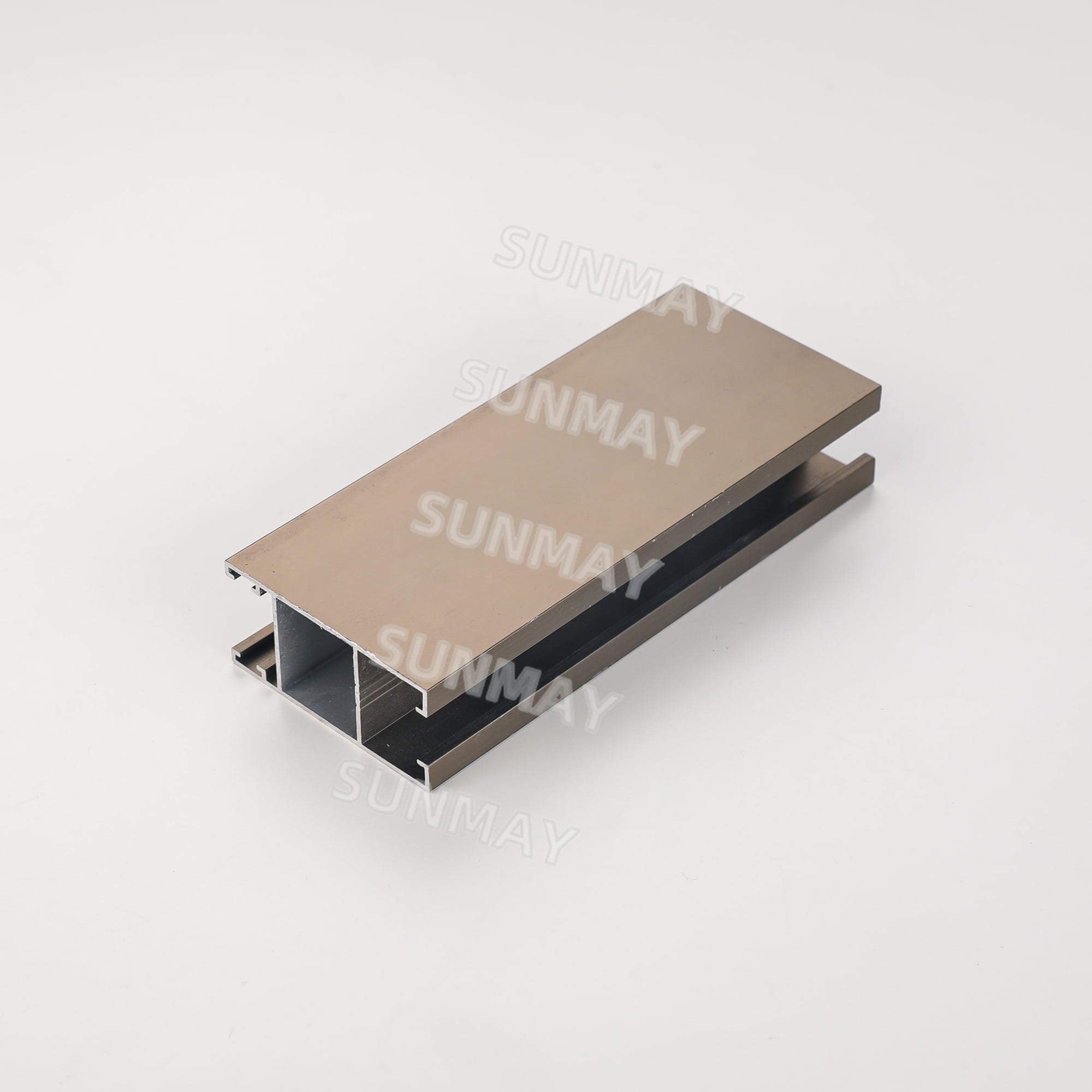

Regarding surface treatments, Sunmay offers multiple options to enhance both protection and appearance:

- Anodizing: Increases surface hardness and corrosion resistance, ideal for exterior decorative applications.

- Powder Coating: Provides a variety of durable colors with excellent UV resistance for aesthetic versatility.

- Wood Grain Transfer Printing: Mimics natural wood textures, perfect for balconies, windows, and garden structures seeking a natural look.

- Electrophoretic Coating: Enhances adhesion and corrosion protection.

We support custom color matching based on customer color charts and RAL standards to ensure consistent color throughout large orders.

Core Features and Advantages Comparison

| Feature/Performance |

Sunmay Aluminum Profiles |

Typical Market Products |

| Material Purity |

Uses ≥99.7% high-purity aluminum ingots, fully traceable raw materials |

High proportion of recycled materials with impurities, batch quality fluctuates |

| Surface Treatment |

Anodic layer ≥10μm, uniform color, strong corrosion resistance |

Uneven anodizing, prone to color inconsistency or poor oxidation |

| Strength Stability |

T5/T6 heat treatment standard, tensile strength above industry average |

No heat treatment or inconsistent strength, affecting structural stability |

| Precision Control |

Dimension tolerance within ±0.10mm, fits precise assembly structures |

Deformations and deviations affect installation efficiency |

| Customization Ability |

Custom dies for cross-section, colors, hardness; fast prototyping |

Limited cross-section options, long lead time for tooling |

| OEM Packaging |

Supports logo printing, project labeling, export-grade packaging |

Generic packaging, unclear labels, complicates customer sorting |

| Export Container Loading |

Flexible mixed or full container loading, optimized space utilization |

No mixed loading, inefficient logistics |

| Price Competitiveness |

Optimized alloy solutions balancing cost control and quality |

Low cost but compromised performance, high post-sale risk |

Summary: In a global project supply context, Sunmay’s construction aluminum alloy profiles help customers effectively reduce procurement risks, enhance installation efficiency, and optimize overall budgets. This makes them ideal for buyers requiring consistent quality in bulk orders.

Customer Problems Addressed

| Common Purchase Challenge |

Sunmay Solution |

| Inconsistent profile colors affecting overall aesthetics |

Standardized RAL color control and pre-shipment color samples ensure batch color consistency |

| Insufficient strength or surface prone to scratching |

Heat treatment and hard anodic film enhance tensile strength and abrasion resistance |

| Varied profile lengths and cross-sections complicate container loading |

Professional loading plans support mixed specification container shipments to reduce logistics costs |

| Delivery delays impact construction schedules |

Scientific production scheduling and dual shifts ensure stable lead times |

| Complex export customs clearance procedures |

Experienced export team familiar with certifications and documentation for South America, Africa, and other markets |

Applications and Industry Uses

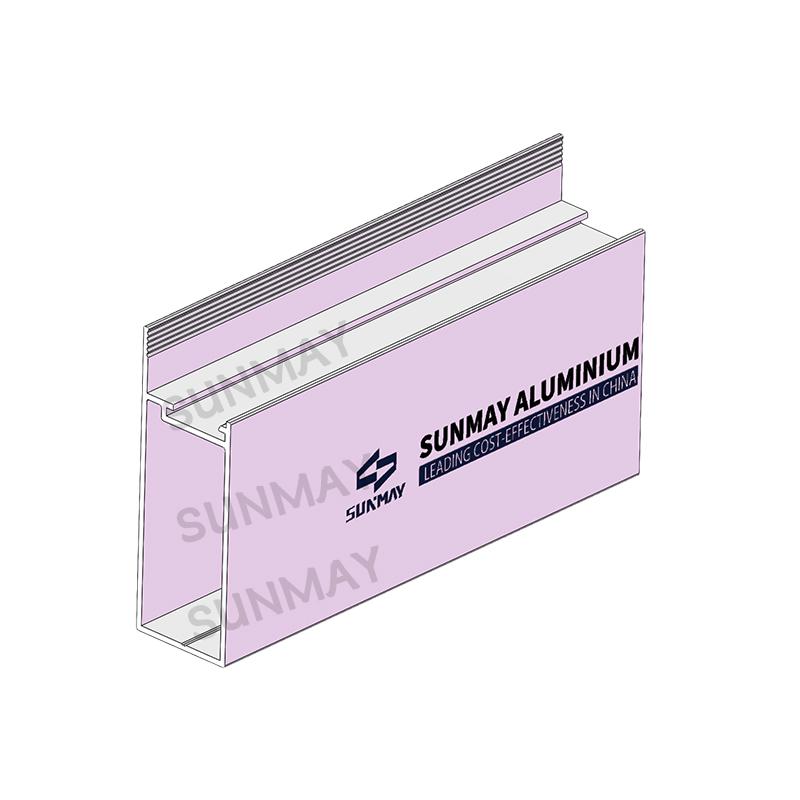

Commercial Building Curtain Walls

In commercial real estate construction, curtain wall structures require aluminum profiles with high strength, lightweight, and excellent weather resistance. Sunmay’s high-strength aluminum alloy profiles, combined with anodized finishes, provide long-lasting structural integrity and maintain a pristine exterior for office buildings, airports, and convention centers.

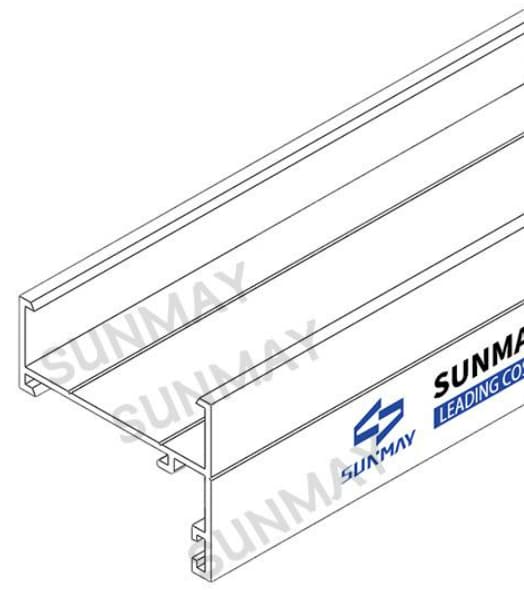

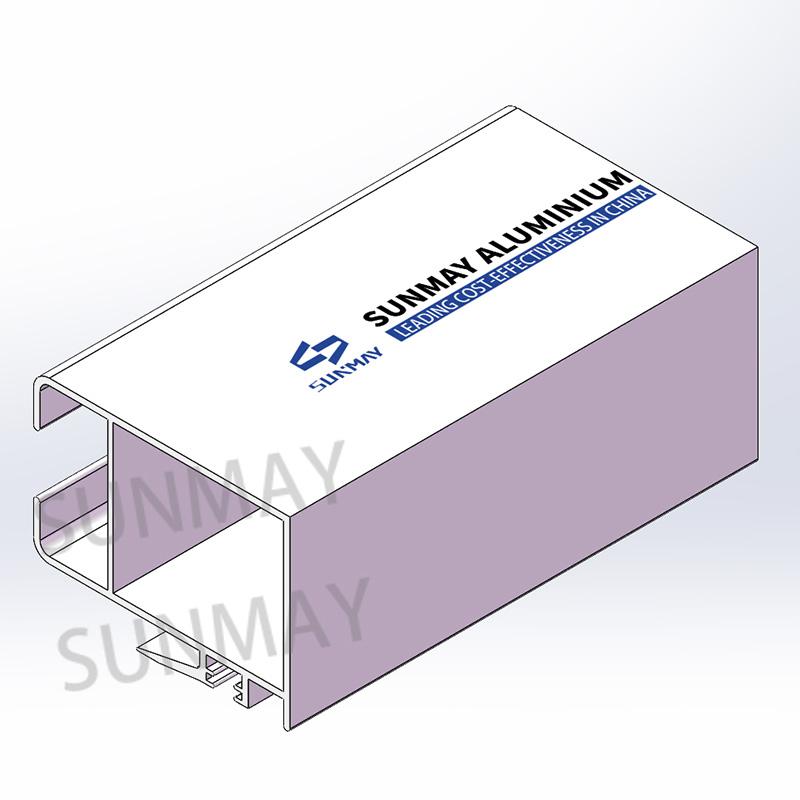

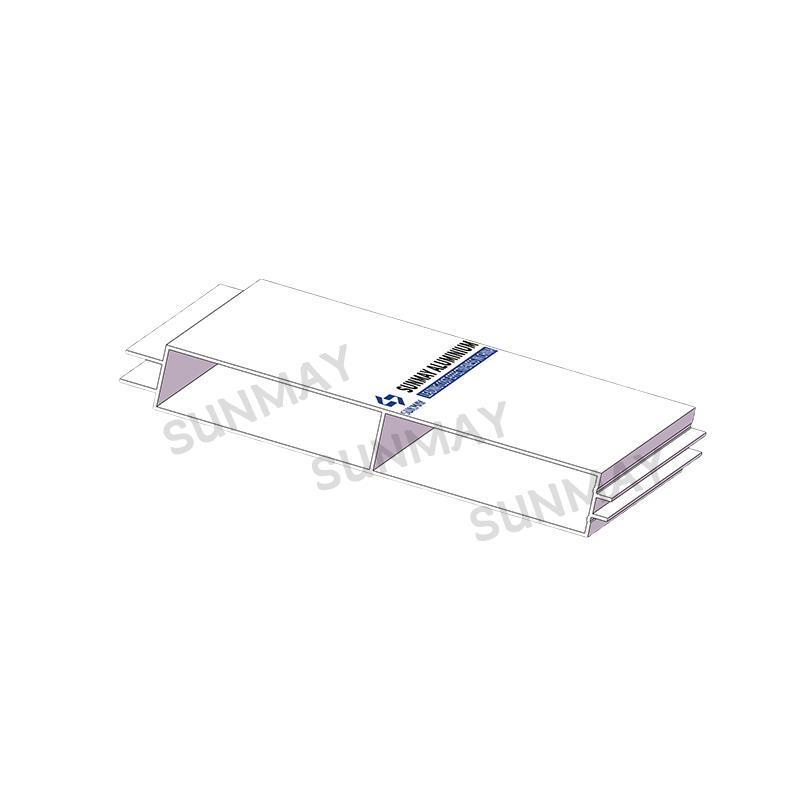

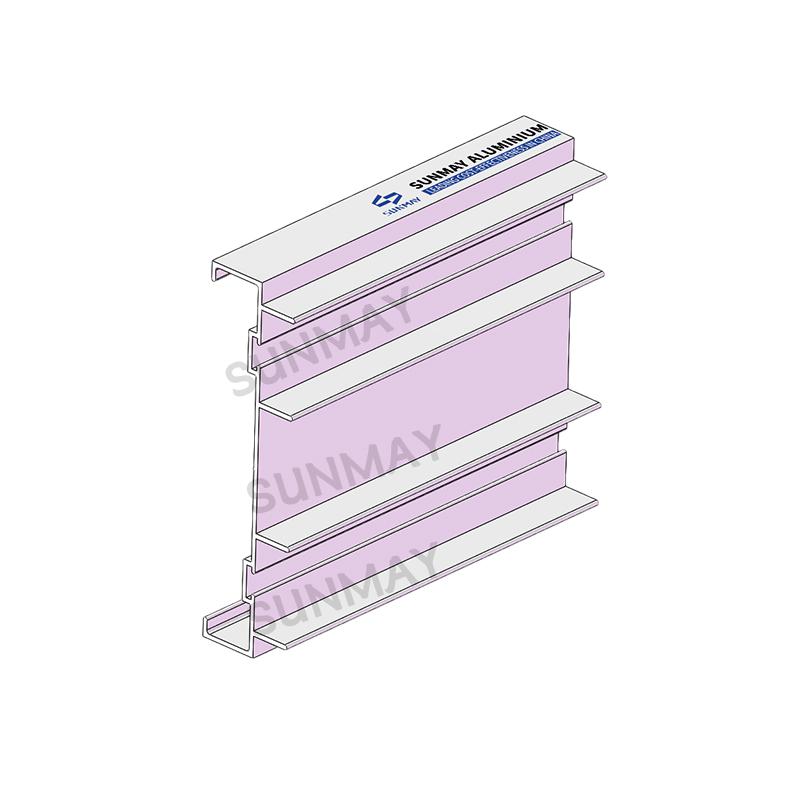

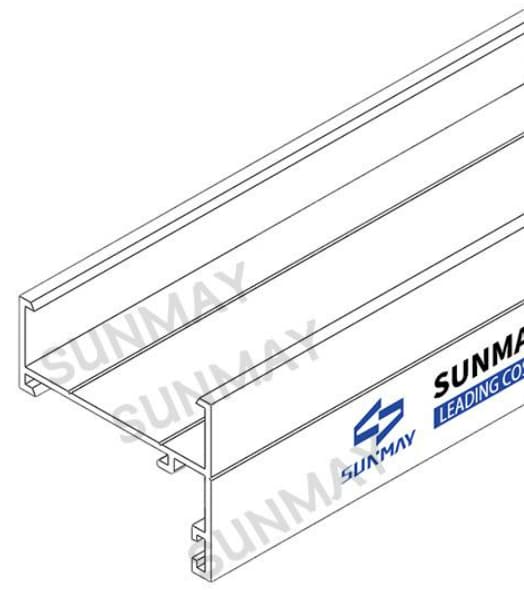

Premium Doors, Windows, and Partition Systems

Door and window systems demand aluminum profiles with excellent sealing and precise assembly compatibility. Sunmay’s profiles undergo high-precision extrusion and T5 heat treatment, making them ideal for sliding doors, folding windows, and partition profiles that enhance sound and thermal insulation while meeting modern architectural aesthetic standards.

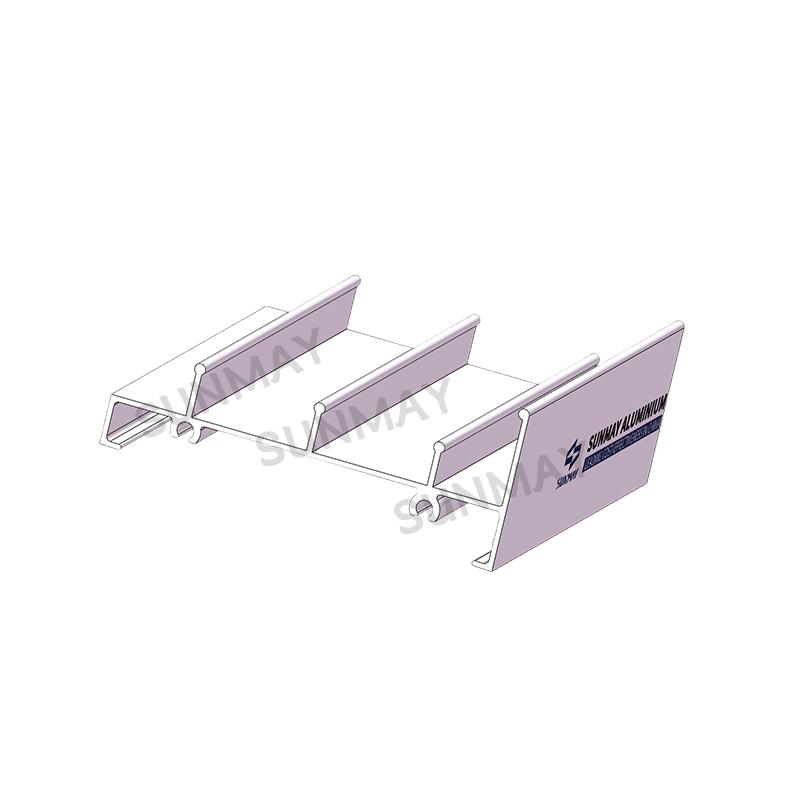

Industrial Equipment Frames and Protective Systems

For solar panel supports, power frameworks, cable trays, and automation equipment structures, Sunmay offers custom aluminum alloy profiles optimized for safety and installation efficiency through alloy composition adjustments and surface treatments, meeting industrial users' rigorous demands.

Strong Capability for Large-Scale Projects and Flexible Export Solutions

Understanding the diverse logistics and supply chain needs of international buyers, Sunmay provides:

- Project-specific production: Customized from sample to mass production with rapid design adjustments.

- Mixed-specification container loading: Accommodates varying lengths and cross-sections to maximize container utilization.

- Multi-port shipping: Flexible export from Shanghai, Ningbo, Qingdao ports to shorten shipping times.

- Complete export documentation: Including Certificates of Origin, FORM E, CO, CIQ as required by destination countries.

- Phased delivery: Supports multi-stage shipments aligned with construction schedules and local warehousing.

Sunmay Brand Assurance: Factory Strength and Export Compliance

Sunmay specializes in exporting high-quality aluminum alloy profiles backed by comprehensive production lines, storage systems, and internationally recognized certifications to ensure traceability, control, and reliability throughout the manufacturing and export process.

- CE Certification: Compliance with EU building and machinery directives.

- RoHS Certification: Environmentally safe materials suitable for global markets.

- REACH Certification: Meets Europe’s stringent chemical compliance standards.

Our experienced quality inspection and packaging teams ensure every shipment meets international standards and customer-specific requirements, including neutral or branded packaging, project labeling, and transport durability with shock-absorbent materials.

Precise Customization and Flexible Delivery to Support Long-Term Partnerships

Sunmay offers a comprehensive customization chain from cross-section design and mold development to sampling and mass production, ensuring quick adaptation to client structural and functional demands:

- Fast prototyping: Samples ready within 7–10 days from drawings.

- Accurate color matching: Supports multiple anodized and coated colors.

- Accessory support: Coordinated delivery of sealing strips, bolts, clips, and installation components.

- Stable lead times: Standard products delivered in 15 days; customized projects flexible.

OEM/ODM Cooperation Process

- Initial communication: Submit profile drawings or samples; specify material, color, surface finish.

- Technical confirmation and prototyping: Mold creation and sample approval.

- Customer confirmation and contract signing: Formalize order and schedule production.

- Packaging design confirmation: Finalize packaging style, logo printing, and labeling.

- Production and shipment: Mass production, container loading, and export documentation.

FAQ

- Q1: What is your minimum order quantity? Do you support small trial orders?

- A: Our standard minimum order quantity is 2 tons. For new customers or testing projects, sample and small batch orders can be negotiated flexibly.

- Q2: Can you customize colors and cross-section shapes?

- A: Yes. We support RAL color anodizing, electrophoretic coating, powder coating, and customized profile dies based on drawings.

- Q3: What is the typical lead time? Can deliveries be staged according to construction schedules?

- A: Regular orders ship within 15–25 days; custom projects require 25–35 days. We offer flexible staged delivery to match project timelines.

- Q4: Is mixed loading of different profile models supported? Do you provide container loading services?

- A: Yes, we support mixed and consolidated shipments. Our professional team optimizes container loading to maximize space utilization.

- Q5: How do you ensure consistent product quality?

- A: All raw materials come from stable suppliers. Production follows ISO quality management systems. Final inspections and packaging protection guarantee stable batch-to-batch consistency.