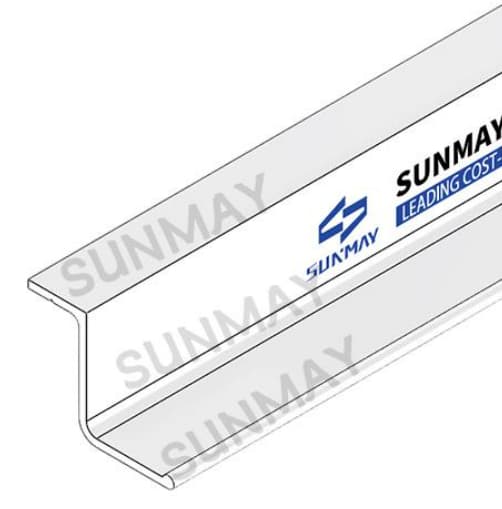

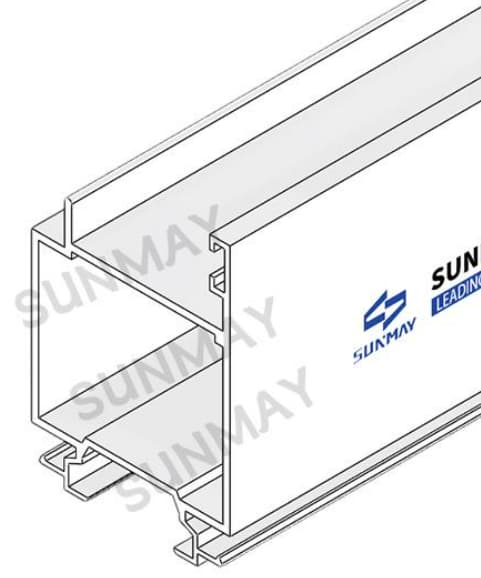

High-quality anodized aluminum profiles ideal for doors, windows, and building projects, offering strength, corrosion resistance, and long-lasting performance.

Material & Temper :

Aluminium Alloy 6063 T5Length :

6 metersApplication :

Window and DoorLead time :

10 to 30 daysExecutable Quality Standard :

GB5237 Or per customer-specified quality standards.Surface Treatment :

Anodize, Electrophoretic coating, Powder Coating, Wooden Grain TransferColor :

Sandblasting Silver Anodized Finish, Sandblasting Champagne Anodized Finish, Black Anodized Finish, White Powder Coated Finish, Wooden Transfer GrainPackaging method :

Each aluminum profile is covered with decorative film and bundled with heat shrink wrap.Our aluminum anodized profiles are crafted from premium 6063-T5 aluminum alloy, produced through precise extrusion processes and advanced anodizing treatment. Each profile is engineered to meet stringent industry standards for strength and corrosion resistance. The lightweight yet robust material, combined with carefully designed cross-sections, provides long-term structural stability suitable for doors, windows, and building frameworks in various environments. The profiles feature multi-layer anodized surfaces that enhance scratch resistance, wear resistance, and color retention, significantly extending the lifespan of doors, curtain walls, and construction structures. This surface treatment ensures compliance with South American and European durability requirements and maintains aesthetic integrity during long-distance shipping and installation. With optimized design and stringent manufacturing processes, our profiles seamlessly integrate with customers’ custom aluminum extrusion solutions, enabling efficient installation and structural consistency.

| Core Performance | Advantage |

|---|---|

| High-strength 6063-T5 aluminum alloy | Provides long-term structural stability, meeting the load requirements of large-scale construction projects |

| Multi-layer anodized surface | Enhances corrosion and wear resistance, reducing long-term maintenance costs |

| Precision extrusion design | Ensures high dimensional accuracy and compatibility with other structural components |

| Customizable cross-sections | Supports personalized designs, fulfilling unique architectural project requirements |

| Eco-friendly and recyclable | Meets international environmental standards and reduces the overall project carbon footprint |

By combining these features, our durable construction profiles address challenges such as insufficient structural strength, fragile surfaces, and high long-term maintenance costs. The profiles’ consistent dimensions also streamline the supply chain, reducing material waste and improving overall project efficiency.

| Customer Pain Point | Solution |

|---|---|

| Profiles prone to corrosion and short lifespan | High-quality aluminum alloy with multi-layer anodizing ensures long-term corrosion resistance and durability |

| Dimensional inaccuracies affecting installation | Precision extrusion and strict quality inspection ensure high dimensional stability for efficient installation |

| Difficulty meeting custom design requirements | Supports various cross-section shapes and surface color customization to adapt flexibly to project needs |

| High costs and material waste | Lightweight, high-strength design reduces material usage and improves transport efficiency |

Clients often encounter challenges with custom aluminum extrusion compatibility in existing architectural projects. Sunmay provides end-to-end design verification and sample testing to ensure profiles integrate seamlessly, minimizing construction risks and reducing rework costs.

Sunmay has a mature management system for large-scale project delivery, covering design optimization, sample validation, production, and logistics. Our export certifications support South America, Europe, Africa, and North America, enabling timely shipment and adherence to local import regulations. Whether handling urgent orders or bulk shipments, we offer flexible production scheduling, inventory management, and global logistics coordination, ensuring projects stay on schedule and reducing construction delays. Our robust delivery capabilities provide clients with confidence in project execution and supply reliability.

Procurement professionals focus on the long-term reliability, cost-effectiveness, and customization flexibility of durable construction profiles. Sunmay delivers high-precision custom aluminum extrusion solutions with diverse surface treatment options to ensure stability under different climates and installation conditions. Sample verification allows buyers to evaluate real product performance before committing to large orders, mitigating risks related to dimensional errors or surface quality. Optimized supply chains, batch delivery options, and professional export support further enhance project efficiency and reduce procurement and construction costs.

Sunmay specializes in high-performance aluminum anodized profiles and custom extrusion solutions. Equipped with advanced fully automated extrusion lines and anodizing production lines, we can handle both small custom orders and large-scale production. Our rigorous quality control system includes dimensional measurement, mechanical testing, and surface inspection, ensuring each batch meets international standards. Our team of design engineers, production technicians, quality managers, and logistics experts provide professional support at every stage. With years of experience and continuous innovation, Sunmay has supplied millions of meters of durable construction profiles worldwide, earning high trust in South American, European, African, and North American markets. We focus not only on product quality but also on enhancing clients’ overall project experience.

Sunmay provides comprehensive custom aluminum extrusion services, from design optimization and sample creation to bulk production. Clients can submit CAD drawings, samples, or functional requirements, and our engineers evaluate and provide improvement suggestions to enhance profile performance and installation efficiency. With flexible extrusion techniques and multiple anodizing and coating options, we deliver highly personalized solutions. Successful projects include residential, commercial, and infrastructure developments, offering unique cross-section designs, color combinations, and functional treatments. Our responsive, high-efficiency customization ensures consistent product quality while meeting diverse project needs.

Sunmay’s OEM/ODM service covers the entire lifecycle from initial consultation to after-sales support. We first assess project type, specifications, budget, and technical standards, offering professional design optimization. During the sample stage, we provide prototypes for client testing and feedback, adjusting as needed to meet exact performance, dimensions, and appearance requirements. In mass production, our quality management system ensures each batch meets strict standards, while logistics teams coordinate optimal shipping, packaging, and labeling solutions. The entire process emphasizes efficient communication and professional service, helping clients reduce management workload and ensure smooth project execution.

Q1: What projects are suitable for Sunmay aluminum anodized profiles?

A1: Our profiles are ideal for residential buildings, commercial offices, public facilities, and industrial constructions. Anodized surfaces ensure corrosion and wear resistance, especially suitable for humid or coastal areas.

Q2: How can I customize dimensions or cross-section shapes?

A2: Clients can provide CAD drawings or reference samples. We offer professional design optimization, sample testing, and bulk production, ensuring profiles match project requirements.

Q3: How does Sunmay support export and shipping?

A3: Sunmay holds global export certifications and collaborates with logistics providers worldwide. We provide tailored packaging and labeling for shipments to South America, Europe, and Africa, ensuring safe transport.

Q4: What about durability and maintenance costs?

A4: Using high-strength 6063-T5 aluminum with multi-layer anodized surfaces, our profiles resist corrosion, wear, and UV exposure, minimizing long-term maintenance and project costs.

Q5: Do you provide OEM/ODM services?

A5: Yes, Sunmay offers complete OEM/ODM services, including design optimization, sample verification, bulk production, and technical support, with responsive communication for all custom needs.

Q6: How do you ensure consistent product quality?

A6: Each batch undergoes strict dimensional, mechanical, and surface quality testing, monitored by our professional quality control team to ensure uniformity.

Q7: What is the production lead time for custom profiles?

A7: Standard batch production is typically 2-4 weeks after sample confirmation. Large or specialized orders can be adjusted according to client needs.

Q8: Are Sunmay profiles eco-friendly and recyclable?

A8: Yes, our aluminum profiles are recyclable and comply with international environmental standards, helping clients reduce project carbon footprint.

Tags :

Whatsapp : +8617366266559

Email : sales@sunmayalu.com

Tel : +86 -17366266559

Hi! Click one of our members below to chat on