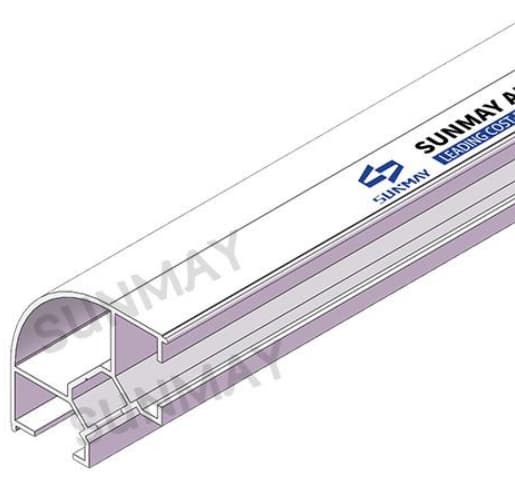

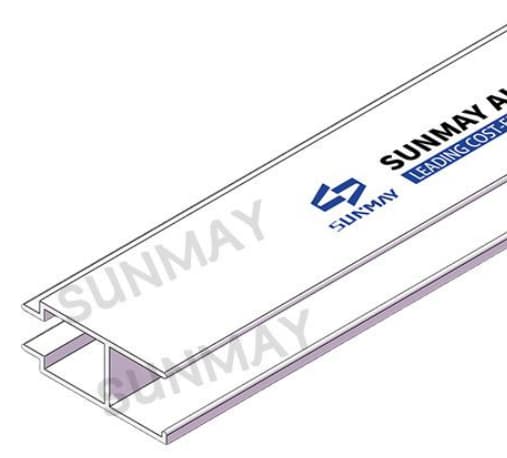

Durable, lightweight, and fully customizable aluminum profiles designed to reduce costs and enhance efficiency in global construction projects.

Material & Temper :

Aluminium Alloy 6063 T5Length :

5.85 metersApplication :

Window and DoorLead time :

10 to 30 daysExecutable Quality Standard :

GB5237 Or per customer-specified quality standards.Surface Treatment :

Anodizing, Powder Coating, Mill FinishColor :

Bronze Anodized, Black Powder Coated, White Powder Coated, Mill FinishedPackaging method :

Each aluminum profile is covered with decorative film and bundled with heat shrink wrap.In modern construction and engineering projects, the choice of materials directly affects efficiency, cost control, and project quality. Sunmay provides custom aluminum profiles with high strength, lightweight, and corrosion resistance, making them the preferred choice in the industry. Each profile is manufactured using precision extrusion techniques, ensuring accurate dimensions and smooth surfaces, reducing on-site processing requirements.

Our cost-effective aluminum profiles optimize raw material usage and production efficiency while applying advanced surface treatments such as anodizing, electrophoresis, and powder coating. Combined with aluminum extrusion for construction technology, these profiles offer high flexibility for complex door, window, and structural applications while keeping construction schedules and budgets under control. Globally, whether in residential projects in South America, commercial buildings in Europe, or public facilities in Africa, Sunmay profiles deliver reliable performance and cost-effective solutions, helping clients maintain a competitive edge.

| Feature | Advantage |

|---|---|

| High Strength and Lightweight | Custom aluminum profiles use premium aluminum alloys, ensuring structural stability while reducing transportation and installation costs. |

| Precise Dimensions and Consistency | Precision extrusion guarantees consistent sizes, improving on-site assembly efficiency and reducing waste. |

| Corrosion Resistance | Surface treatments including anodizing, powder coating, and electrophoresis enhance durability in coastal, humid, or high-UV environments. |

| Cost Optimization | Cost-effective aluminum profiles lower procurement and maintenance costs through optimized material utilization and efficient production. |

| Stable Supply | Large-scale production and flexible inventory management ensure timely delivery for global projects, preventing construction delays. |

These advantages allow clients to optimize costs without compromising quality. High-strength profiles handle complex structural needs, while lightweight designs reduce logistics and installation difficulty. Corrosion-resistant finishes adapt to various climates, minimizing maintenance. Stable supply and production flexibility guarantee smooth project execution, even for large international projects, making aluminum extrusion for construction both aesthetically pleasing and functionally reliable.

| Pain Point | Problem | Sunmay Solution |

|---|---|---|

| Insufficient Strength | Standard profiles cannot support large-scale structures | High-strength custom aluminum profiles ensure structural safety and reduce post-construction modifications. |

| Corrosion Issues | Profiles exposed to coastal or humid areas tend to rust | Anodizing, powder coating, and electrophoresis enhance durability and prolong lifespan. |

| Unstable Supply | Project delays due to inconsistent material availability | High production capacity, flexible inventory, and global logistics ensure on-time delivery. |

| Limited Customization | Profiles cannot meet specific size, color, or finish requirements | Multiple specifications and finishes available to quickly meet unique project demands. |

| High Cost | Material and maintenance expenses strain budgets | Using cost-effective aluminum profiles reduces procurement and long-term maintenance costs. |

Our solutions address real construction challenges. For example, anodized profiles prevent rust in coastal projects, reducing rework. Flexible customization meets diverse design requirements worldwide, while cost optimization strategies combine efficient production and material usage to deliver excellent value for clients.

Sunmay has extensive experience delivering large-scale international projects across South America, Europe, Africa, and North America. Advanced production lines and rigorous quality control ensure product stability. Combined with professional logistics services, including sea, air, and land transport, clients receive materials on time. Leveraging cost-effective aluminum profiles helps control material costs while enhancing construction efficiency and quality assurance.

Sunmay’s factory features advanced extrusion equipment, automated cutting, and surface treatment lines, strictly adhering to ISO standards. Quality control covers raw materials, production, processing, and shipment, with thorough checks on dimensions, hardness, and surface quality. Experienced engineering teams provide design optimization, sample validation, and customized solutions. Reliable production capacity and premium service make Sunmay a trusted supplier of custom aluminum profiles and aluminum extrusion for construction worldwide.

Sunmay offers flexible customization, including profile length, cross-section, wall thickness, surface treatment, and color. European clients prioritize durability and aesthetics, while South American clients focus on cost efficiency and shipping logistics. Through rapid sample verification, trial production, and flexible scheduling, Sunmay ensures window aluminum extrusion meets diverse project requirements. Both large and small orders are efficiently processed, guaranteeing on-time completion.

Q1: What are the benefits of custom aluminum profiles?

A: Lightweight, durable, corrosion-resistant, and suitable for doors, windows, and building facades.

Q2: Can aluminum extrusion for construction be used outdoors?

A: Yes, anodized or powder-coated profiles resist moisture, UV rays, and corrosion.

Q3: What customization options are available?

A: Length, wall thickness, surface finish, color, and small-batch production.

Q4: How long is delivery time?

A: Standard profiles: 2–4 weeks; custom orders: 4–8 weeks depending on size and quantity.

Q5: Which industries use these profiles?

A: Construction, commercial buildings, hotels, stadiums, and residential projects.

Q1: What sizes are available?

20–300mm outer diameter, 2–25mm wall thickness, customizable per project.

Q2: How strong are these aluminum profiles?

High-strength materials support large-scale structures while reducing weight.

Q3: What surface treatments are offered?

Anodizing, electrophoresis, and powder coating enhance durability and aesthetics.

Q4: Are they suitable for coastal or humid areas?

Yes, treated profiles resist corrosion and maintain long-term stability.

Q5: Delivery time for custom orders?

2–4 weeks for standard profiles, 4–8 weeks for custom sizes and finishes.

Q6: How is quality consistency ensured?

Strict QC ensures all dimensions, hardness, and appearance match approved samples.

Q7: Do you support international shipping?

Yes, to South America, Europe, Africa, and North America with professional logistics solutions.

Tags :

Whatsapp : +8617366266559

Email : sales@sunmayalu.com

Tel : +86 -17366266559

Hi! Click one of our members below to chat on