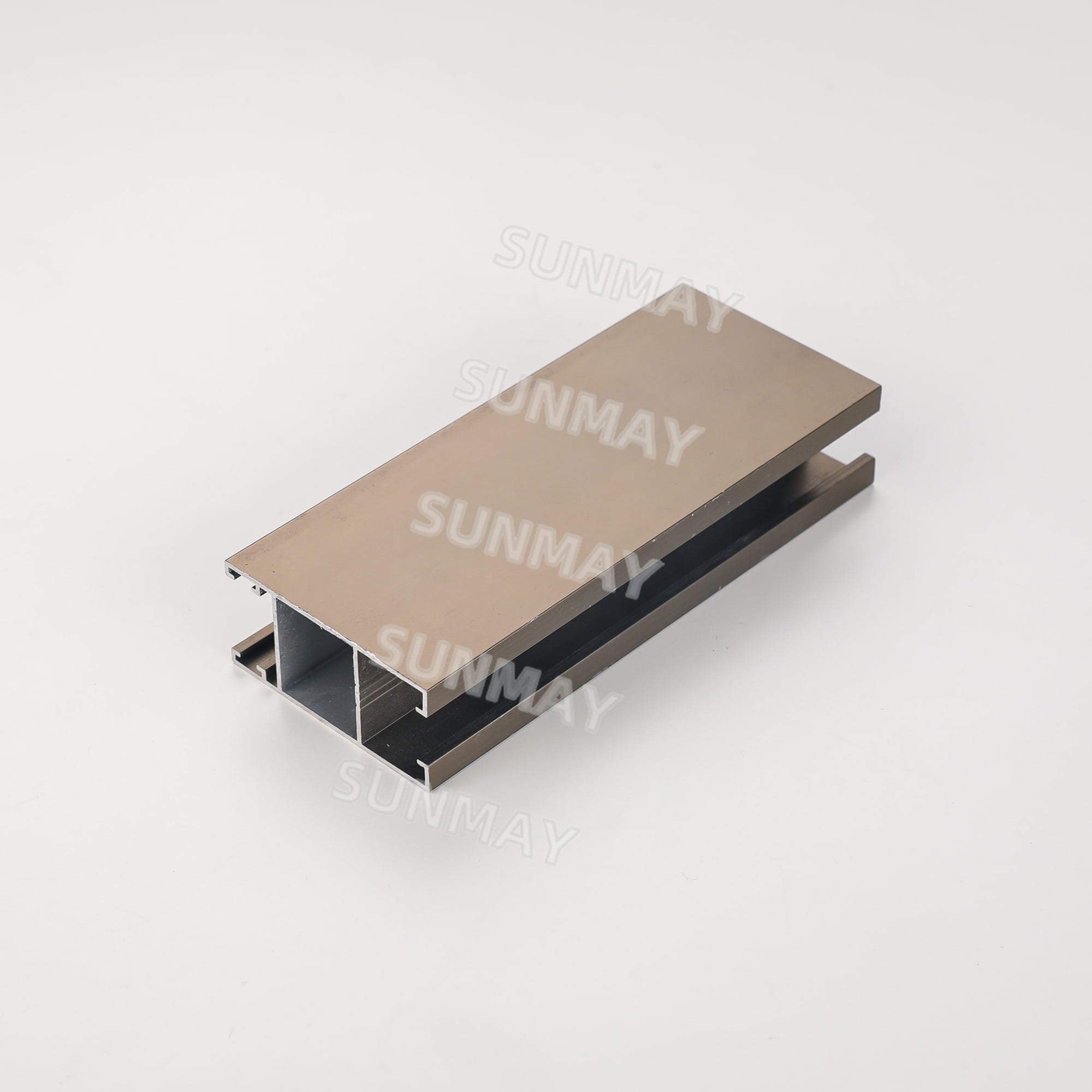

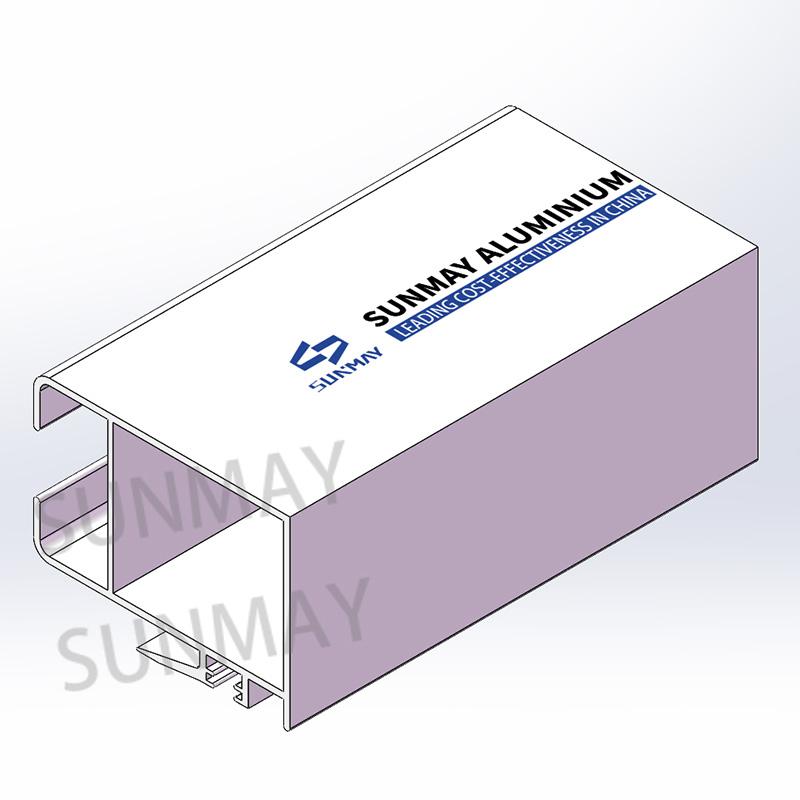

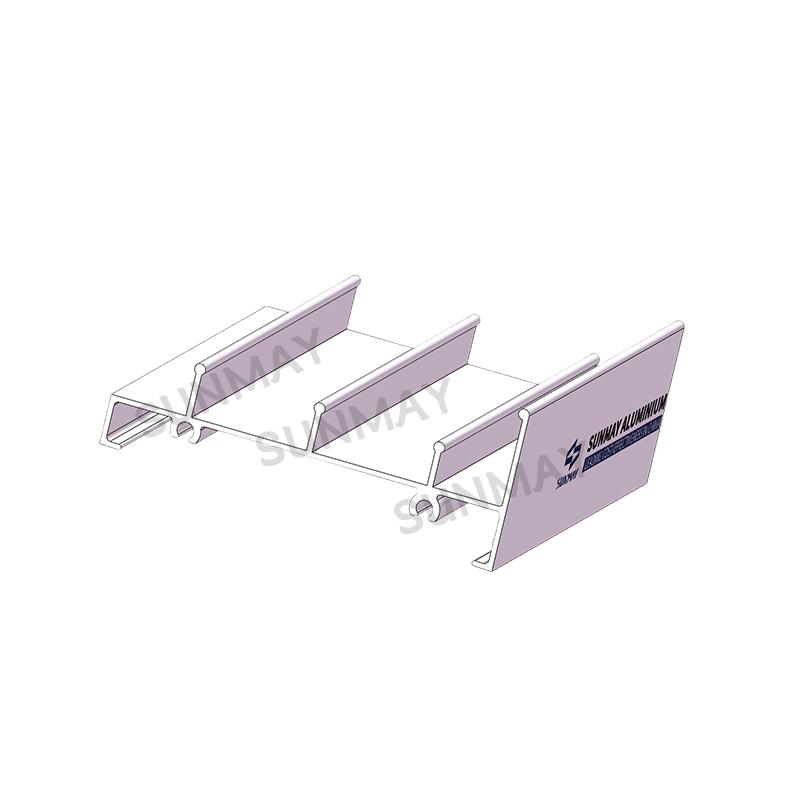

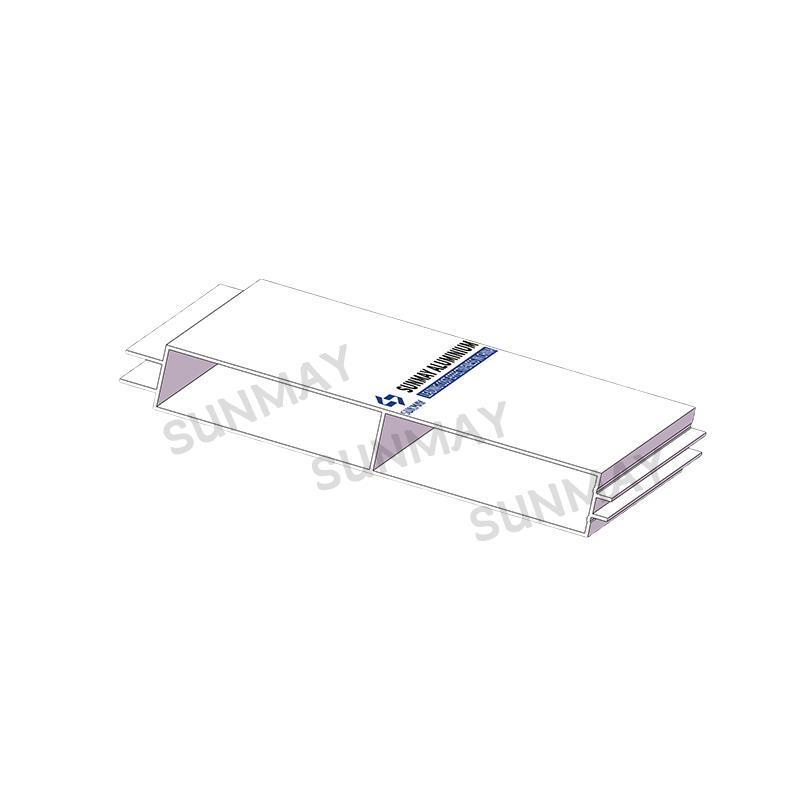

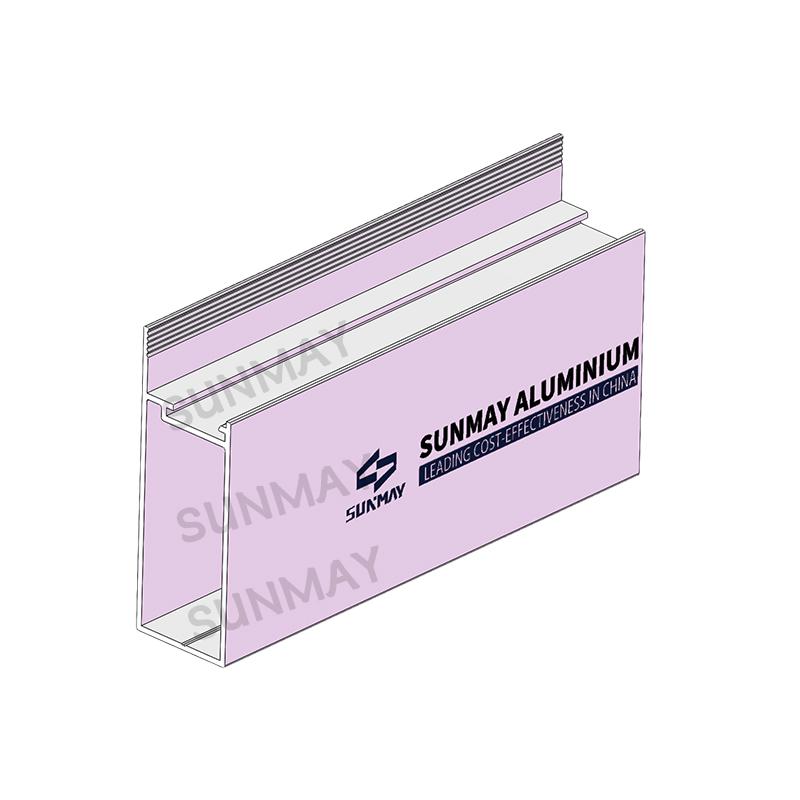

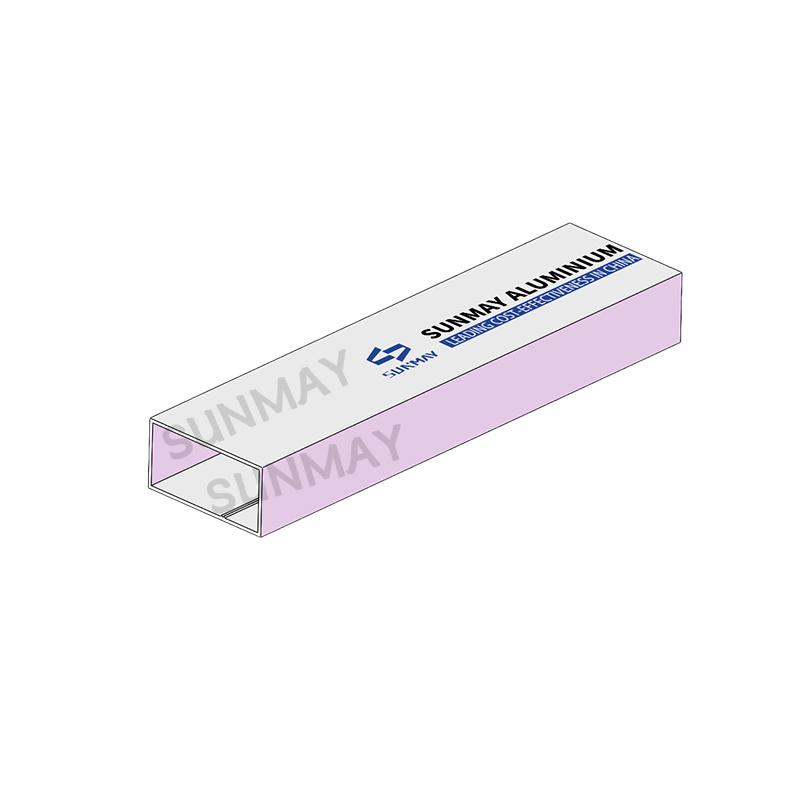

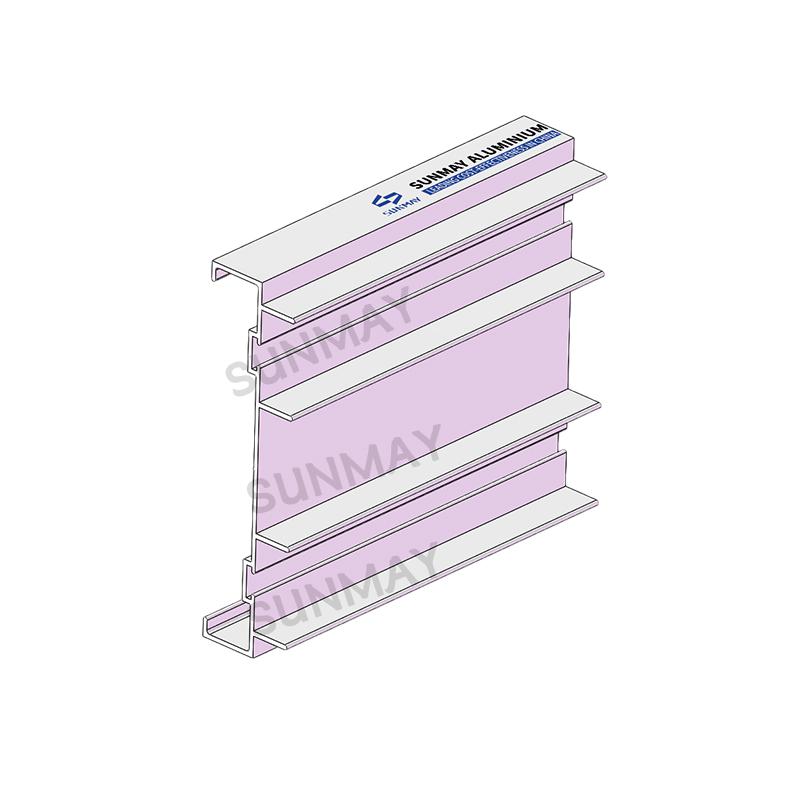

Our cost effective aluminum profiles are made from premium 6063 aluminum alloy, known for its excellent strength and corrosion resistance, making it ideal for door and window applications. The profiles are manufactured with advanced extrusion technology, ensuring precise dimensions and smooth surface finishes that meet international standards. Additionally, the aluminum profiles for doors feature innovative structural designs that improve sealing performance and durability. Surface treatments such as anodizing and powder coating enhance weather resistance and offer customizable colors, catering to diverse market demands while maintaining sustainability and compliance with global environmental regulations.

Core Features and Advantages

| Key Feature | Benefit |

|---|---|

| High-grade 6063 Aluminum Alloy | Ensures structural integrity and long service life under various climate conditions. |

| Precision Extrusion Process | Delivers consistent profile dimensions, reducing installation time and errors. |

| Anodized Surface Treatment | Improves corrosion resistance and maintains aesthetic appeal over time. |

| Customizable Colors and Finishes | Allows tailored designs to meet branding and architectural needs. |

| Compliance with International Standards | ISO, RoHS, and REACH certifications guarantee safety and export readiness. |

These cost effective aluminum profiles not only provide superior mechanical performance but also offer significant cost savings, helping clients optimize budgets. The stable supply chain and flexible customization options streamline procurement, especially for large volume orders. Our intelligent production lines and rigorous quality management ensure consistent high-quality aluminum extrusion products from China, fully meeting global market demands.

Customer Pain Points and Solutions

| Customer Concern | Our Solution |

|---|---|

| Inconsistent profile dimensions | Utilize precision molds and automated inspection to ensure dimensional accuracy. |

| Surface corrosion and uneven colors | Apply advanced anodizing and coating technologies for durable and uniform finishes. |

| Long delivery lead times | Optimize supply chain and production scheduling for timely shipments. |

| Cost control challenges | Offer competitively priced products and support bulk and custom orders to reduce unit costs. |

By continuously adopting advanced technology and optimizing workflow, we enhance product competitiveness. Transparent order tracking and communication reduce procurement risks, ensuring a smooth experience for clients worldwide seeking reliable aluminum extrusion China products.

Product Application Scenarios

Our aluminum profiles for doors and windows find wide applications across various sectors:

- Residential Buildings: Used in premium door and window frames that combine aesthetics and durability.

- Commercial Complexes: Suitable for large-scale commercial façade systems, enhancing structural strength and energy efficiency.

- Industrial Facilities: Ideal for factory doors and windows requiring robustness and easy maintenance.

- Public Infrastructure: Deployed in schools, hospitals, and other public buildings, meeting strict safety and environmental standards.

- Outdoor Installations: Used for balconies, fences, and other structures exposed to harsh weather, benefiting from excellent corrosion resistance.

These diverse application scenarios demonstrate the versatility and value of our aluminum extrusion products, reflecting their strong performance and cost-efficiency tailored for different market needs.

Large-Scale Project Delivery and Export Capability

Sunmay possesses a professional project management team and complete export qualifications, ensuring efficient production and timely delivery of large orders. With advanced warehousing and diverse logistics solutions, we guarantee safe and fast shipping worldwide. Our familiarity with export procedures minimizes customs risks, providing customers with a worry-free purchasing experience.

Sunmay Brand and Factory Strength

Sunmay factory is equipped with fully automated aluminum extrusion production lines and possesses strong R&D capabilities. Our strict ISO9001 quality management system guarantees compliance with international standards throughout the entire production process. Our dedicated teams in production, quality control, and customer service are committed to delivering stable, high-quality aluminum extrusion China products to global customers.

Excellent Customization Capabilities

Sunmay offers highly flexible customization services, supporting a wide range of profile designs, dimensions, and surface treatments. Our technical team collaborates closely with clients from design to sample validation, enabling rapid response to market needs. We have successfully provided tailored aluminum profiles for doors solutions for many international landmark projects, earning strong client recognition.

OEM/ODM Cooperation Process

Our cooperation process includes requirement communication, design development, sample confirmation, mass production, and after-sales support. Sunmay emphasizes efficient communication and professional services, ensuring customer demands are accurately realized. Transparent process management reduces procurement risks and enhances product competitiveness.

FAQ

- What materials are used in your aluminum profiles for doors and windows?

- We primarily use high-quality 6063 aluminum alloy to ensure excellent strength and corrosion resistance suitable for various environments.

- Can you provide customized aluminum extrusion profiles?

- Yes, we offer full customization options including dimensions, surface finishes, and colors to meet project-specific requirements.

- How does Sunmay ensure timely delivery?

- We maintain efficient production scheduling and logistics management, supported by a robust supply chain to guarantee prompt shipments.

- What certifications do your aluminum profiles hold?

- Our products comply with ISO9001, RoHS, and REACH standards, ensuring environmental safety and export readiness.

- How do you control the quality of your aluminum extrusion products?

- Strict quality control is implemented at every production stage using advanced inspection equipment to ensure consistent product quality.