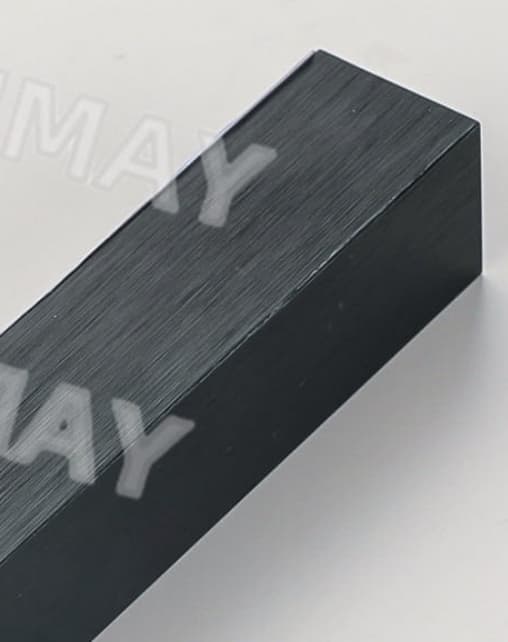

Durable brushed black anodized aluminum extrusion tube, ideal for doors, windows, and structural projects with corrosion resistance and modern appeal.

Material & Temper :

Custom Aluminum Alloy with Heat TreatmentApplication :

Architectural, Decorative Home and Industrial Aluminum ProfilesLead time :

10 to 30 daysExecutable Quality Standard :

GB5237, TS16949, EN12020, EN755, EN573, Or according to customer agreement standardsSurface Treatment :

Brushed Stained AnodizedColor :

BlackPackaging method :

Customized according to customer requirementsOur brushed black anodized aluminum tube is made from high-strength aluminum alloy, processed through precision extrusion and anodizing to create a unique matte black finish. This surface treatment not only enhances aesthetics but also improves corrosion resistance and oxidation protection, ensuring long-lasting durability in various environments. The tube wall thickness is uniform, and dimensional tolerances are strictly controlled, providing reliable structural stability.

For construction applications, our aluminum extrusion profiles for construction combine lightweight design with high load-bearing capacity, suitable for large window frames, curtain walls, and decorative components while ensuring ease of installation. Using advanced extrusion dies and CNC processing, we achieve precision up to ±0.1mm, ensuring tight component fit and minimizing installation errors. As a leading anodized aluminum extrusion supplier, we strictly manage raw material procurement, extrusion, anodizing, and surface finishing processes, ensuring stable product performance in every batch. Whether for mass production or custom specifications, we deliver high-quality solutions to meet global market demands.

| Key Feature | Advantage | Problem Solved |

|---|---|---|

| High-Strength Aluminum Alloy | Provides excellent load-bearing capacity | Prevents deformation in construction frames |

| Precision Anodizing | Enhances corrosion resistance and appearance | Extends service life, reduces maintenance cost |

| Dimensional Accuracy ±0.1mm | Ensures precise installation | Reduces construction time and adjustment effort |

| Custom Sizes | Flexible to meet project requirements | Supports diverse engineering designs |

| Global Export Capability | Supports international delivery | Optimizes supply chain and reduces logistics risk |

Our brushed black anodized aluminum tube and aluminum extrusion profiles for construction combine high strength and corrosion resistance with precise manufacturing, improving construction efficiency. Customers can reduce material waste, shorten installation time, and lower long-term maintenance costs. As a trusted anodized aluminum extrusion supplier, we offer a variety of specifications to meet different project requirements.

| Pain Point | Solution |

|---|---|

| Aluminum easily oxidizes or surface is not durable | Use matte anodizing to enhance corrosion resistance |

| Non-uniform specifications, difficult installation | Provide custom sizes with ±0.1mm precision |

| Long supply lead times | Implement production scheduling and global logistics for on-time delivery |

| Damage during transportation | Reinforced packaging and protection measures |

| Diverse project designs | Flexible custom solutions to meet different designs |

Clients often face challenges such as oxidation, installation difficulty, or supply delays. Our brushed black anodized aluminum tube uses advanced anodizing to prolong lifespan and offers precise dimensions and multiple specifications, addressing installation and design diversity. As a reliable anodized aluminum extrusion supplier, we also provide a robust logistics system for on-time delivery, reducing procurement risks.

As an experienced anodized aluminum extrusion supplier, we handle large-scale projects with mature processes and rich experience. From North American residential communities to European commercial complexes and Middle Eastern industrial facilities, we offer timely delivery solutions. Certified with ISO quality management, we possess full export qualifications to meet customs and shipping requirements globally. We collaborate with international logistics partners for air, sea, and multimodal transport, ensuring safe, efficient delivery. Coupled with flexible production planning and inventory management, customers can align orders with project schedules, optimizing the supply chain and reducing overall procurement risk and cost.

Sunmay, a professional aluminum extrusion manufacturer, operates advanced equipment including high-precision extrusion presses, CNC cutting machines, and automated anodizing production lines. We implement strict raw material inspection, online production monitoring, and final product testing, ensuring consistent quality for every brushed black anodized aluminum tube and aluminum extrusion profiles for construction. Our team of experienced engineers and technicians provides technical support and tailored solutions. Combined with modern management systems and continuous improvement processes, Sunmay guarantees production efficiency and product consistency, earning a strong reputation as a reliable anodized aluminum extrusion supplier for global clients.

Sunmay offers flexible customization to meet diverse global market demands. From tube diameter, wall thickness, and surface color to extrusion profile design, we can produce according to client specifications. European and American markets prefer lightweight and precise profiles, while Middle Eastern and Asian projects emphasize corrosion resistance and aesthetics. For example, a German construction company required ultra-thin black aluminum tubes for curtain wall design. We optimized extrusion and anodizing parameters to deliver precise profiles that met design requirements and facilitated smooth installation. Our rapid response and flexible customization help clients succeed in different markets worldwide.

Q1: What are aluminum extrusion profiles for construction?

A1: They are construction profiles produced via aluminum extrusion, used for windows, curtain walls, and decorative structures, offering lightweight design and high load-bearing capacity.

Q2: How to choose a reliable anodized aluminum extrusion supplier?

A2: Consider production equipment, quality control system, export qualifications, customization capabilities, and review project cases and client feedback.

Q3: What applications are suitable for brushed black anodized aluminum tube?

A3: Ideal for high-end residential, commercial, industrial, and public projects, combining aesthetics with corrosion resistance.

Q4: What are the advantages of aluminum surface treatment?

A4: Anodizing improves corrosion and wear resistance, enhances appearance, and extends product life.

Q1: Can products be customized in size and color?

A1: Yes, we provide various specifications including diameter, wall thickness, and surface color to meet different design and construction needs.

Q2: What is the typical delivery time?

A2: Sample production takes about 7–10 days. Mass production depends on order quantity and specifications, generally within 3–6 weeks.

Q3: Are the products suitable for outdoor use?

A3: Yes, our brushed black anodized aluminum tube with matte anodizing is highly corrosion-resistant and suitable for various outdoor environments.

Q4: How is product quality ensured?

A4: We implement strict raw material inspection, production monitoring, and final product testing to ensure precise dimensions, smooth surfaces, and stable performance.

Q5: Do you support global exports?

A5: Sunmay holds full export qualifications and collaborates with international logistics partners for safe and efficient global delivery.

Q6: Can technical support be provided?

A6: Yes, our experienced engineers provide design optimization advice, installation guidance, and project solutions.

Q7: How do you ensure consistency for large orders?

A7: High-precision extrusion equipment, strict production processes, and comprehensive quality control ensure uniform specifications, performance, and appearance in mass production.

Tags :

Whatsapp : +8617366266559

Email : sales@sunmayalu.com

Tel : +86 -17366266559

Hi! Click one of our members below to chat on