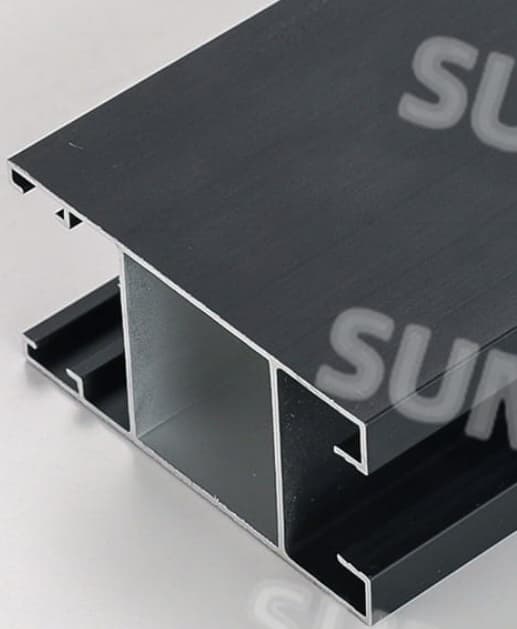

Durable black anodized aluminum extrusion profiles with satin finish, ideal for windows, doors, and structural applications, combining aesthetics and long-term performance.

Material & Temper :

Custom Aluminum Alloy with Heat TreatmentApplication :

Architectural, Decorative Home and Industrial Aluminum ProfilesLead time :

10 to 30 daysExecutable Quality Standard :

GB5237, TS16949, EN12020, EN755, EN573, Or according to customer agreement standardsSurface Treatment :

Anodized Satin FinishColor :

BlackPackaging method :

Customized according to customer requirementsOur satin finish aluminum extrusions are produced with precision extrusion technology, ensuring consistent wall thickness and dimensional accuracy. The profiles undergo a high-quality anodizing process, which enhances surface hardness, prevents oxidation, and provides a uniform black finish. These aluminum construction profiles are suitable for residential, commercial, and industrial applications, delivering both structural support and visual elegance. With excellent machinability and compatibility with various connectors and fittings, our profiles are versatile for different project designs.

| Feature | Benefit | Customer Value |

|---|---|---|

| High-strength aluminum alloy | Supports large spans and structural loads | Reduces material usage and overall construction costs |

| Black anodized satin finish | Resists corrosion, scratches, and UV exposure | Extends product lifespan and minimizes maintenance |

| Precision extrusion | Ensures dimensional accuracy and consistency | Facilitates faster assembly and installation |

| Customizable profiles | Adaptable dimensions and cross-sections | Meets unique project requirements and local regulations |

Each feature of our black anodized aluminum profiles addresses common construction challenges. By using durable, precise, and customizable extrusions, clients can optimize structural integrity, reduce costs, and streamline supply chain operations.

| Pain Point | Solution |

|---|---|

| Inconsistent profile dimensions | Sunmay applies advanced extrusion and quality control for consistent size |

| Surface corrosion and damage | Our anodizing process protects profiles in harsh environments |

| Difficulty in project-specific customization | Flexible design and production options tailored to client needs |

| Delayed delivery impacting project timelines | Efficient production planning and global logistics ensure timely delivery |

By addressing these challenges, our satin finish aluminum extrusions provide reliable solutions for complex construction requirements, ensuring project success across multiple regions.

Our aluminum construction profiles are widely used in commercial buildings, residential complexes, industrial facilities, and public infrastructure. In Brazil, they serve as durable window frames in high-rise apartments. In Europe, the profiles are applied to office curtain walls, enhancing both aesthetics and structural support. In African industrial plants, these extrusions provide corrosion-resistant frameworks for machinery enclosures. In North America, they are incorporated into modular construction systems, reducing installation time while maintaining strength. Additionally, custom profiles are used in interior partition systems, storefronts, and architectural accents, showcasing versatility in design and function.

Sunmay has extensive experience delivering large-scale projects worldwide. Our facilities support bulk production of black anodized aluminum profiles with strict quality control to meet international standards. Export capabilities include coordination with global freight providers, ensuring safe and timely shipment to South America, Europe, Africa, and North America. Comprehensive documentation and packaging solutions are provided for easy handling and compliance with customs regulations, helping clients streamline logistics and avoid delays.

Sunmay operates state-of-the-art extrusion lines and anodizing equipment, combined with advanced inspection tools to guarantee precision and quality. Our quality management system monitors every step, from raw material selection to final packaging. The experienced engineering team collaborates with clients to optimize profiles for both performance and aesthetics. Continuous training programs ensure our staff remains at the forefront of industry standards, making Sunmay a reliable partner for satin finish aluminum extrusions and aluminum construction profiles worldwide.

Sunmay offers flexible customization for dimensions, cross-section shapes, and surface treatments to meet diverse project requirements. Regional market differences, such as climate or design preferences, are considered during the design process. Clients can request tailored solutions for door frames, window systems, curtain walls, or industrial structures. Rapid sample production allows clients to verify functionality and appearance before mass production, ensuring that black anodized aluminum profiles perfectly align with project specifications.

Sunmay offers premium black anodized aluminum profiles with a satin finish, designed for doors, windows, and diverse construction projects. Made from high-quality aluminum alloys, these extrusions combine durability, corrosion resistance, and aesthetic appeal. The satin surface provides a smooth, fingerprint-resistant finish, enhancing both the appearance and long-term performance of architectural and industrial applications. Ideal for projects across South America, Europe, Africa, and North America, our profiles meet the strict requirements of modern construction and design standards.

Our OEM/ODM process includes seven key steps.

1) Requirement communication: clients provide project specs, and we offer technical evaluation.

2) Design proposal: engineers create optimized profile designs.

3) Sample production: prototypes are made for client approval. 4) Sample confirmation: adjustments are made based on feedback.

5) Mass production: high-precision extrusion ensures consistent quality.

6) Logistics arrangement: optimal shipping solutions for timely delivery.

7) After-sales support: technical guidance and problem resolution.

This structured approach ensures efficient communication, flexible customization, and reliable results for all aluminum construction profiles projects.

Q1: What is black anodized aluminum profiles?

A1: Black anodized aluminum profiles are aluminum extrusions treated with a black anodic coating, providing corrosion resistance, scratch protection, and aesthetic appeal. They are ideal for doors, windows, and industrial applications.

Q2: What are the advantages of satin finish aluminum extrusions?

A2: Satin finish aluminum extrusions feature a smooth, fingerprint-resistant surface with excellent corrosion resistance. They enhance both appearance and structural durability in construction and industrial projects.

Q3: Where are aluminum construction profiles used?

A3: Aluminum construction profiles are suitable for commercial buildings, residential projects, industrial facilities, and infrastructure. Their high strength and lightweight design allow for flexible architectural solutions.

Q4: How to choose a reliable aluminum profile supplier?

A4: Consider product quality, precision, certifications, and delivery capabilities. Sunmay offers strict quality control, custom services, and global logistics support for reliable project execution.

Q1: Can Sunmay black anodized aluminum profiles be used outdoors?

A1: Yes, our profiles have excellent corrosion resistance and UV protection, suitable for various climates in South America, Europe, Africa, and North America, ideal for doors, windows, and curtain walls.

Q2: How can I customize satin finish aluminum extrusions?

A2: Provide drawings or samples, and Sunmay engineers will optimize design for dimensions, cross-section, and surface finish. Customization ensures profiles meet specific project requirements.

Q3: What is the lead time for aluminum construction profiles?

A3: Standard profiles have short production cycles, while customized profiles depend on complexity and quantity. Efficient production planning and logistics ensure timely delivery globally.

Q4: Does Sunmay offer technical support and installation guidance?

A4: Yes, we provide pre-sale and post-sale support, including profile selection, structural advice, installation guidance, and troubleshooting to reduce project risk.

Q5: How does Sunmay ensure product quality?

A5: Sunmay implements multi-layer quality control, including raw material inspection, dimension measurement, surface checking, and performance testing. All products meet ISO9001 and CE standards for reliable, high-quality aluminum profiles.

Tags :

Whatsapp : +8617366266559

Email : sales@sunmayalu.com

Tel : +86 -17366266559

Hi! Click one of our members below to chat on