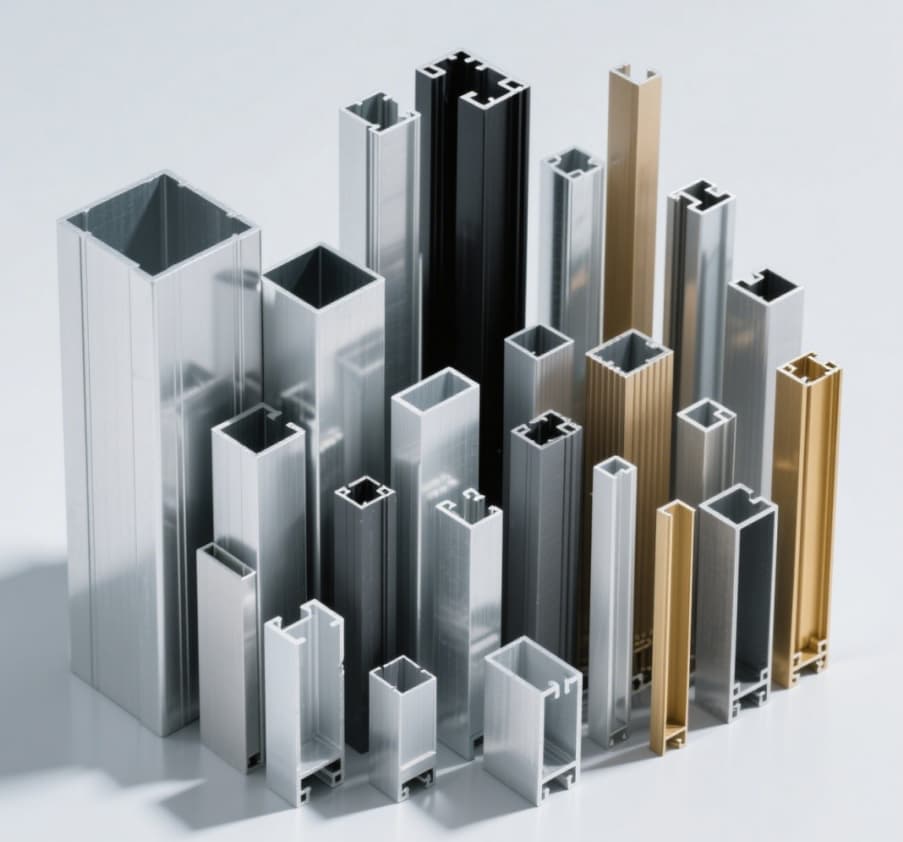

Durable moonlight gray powder coating for aluminum surfaces, providing corrosion resistance, smooth finish, and ideal for doors, windows, and construction projects.

Material & Temper :

Custom Aluminum Alloy with Tempering ProcessApplication :

Architectural, Decorative Home and Industrial Aluminum ProfilesLead time :

10 to 30 daysExecutable Quality Standard :

GB5237, TS16949, EN12020, EN755, EN573, Or according to customer agreement standardsSurface Treatment :

Powder CoatingColor :

Moonlight Gray No. NZ-7337Sunmay's alloy powder coating is designed on high-performance aluminum alloy substrates using advanced electrostatic spraying and curing techniques, achieving a precise and elegant moonlight gray aluminum finish. The coating provides excellent corrosion resistance and a smooth, uniform surface free of bubbles and peeling, protecting aluminum profiles in harsh environments for long-term use.

Manufactured under strict industrial standards, the powder coating uses environmentally friendly materials with low VOC emissions, ensuring safe and sustainable use. The coating's strong adhesion, scratch resistance, and UV protection make it ideal for doors, windows, furniture, and decorative architectural materials, helping clients reduce maintenance costs and extend service life.

| Key Performance | Advantage | Customer Value |

|---|---|---|

| High adhesion powder coating | Strong bond with aluminum, resists peeling | Enhances durability, reduces maintenance frequency, lowers long-term costs |

| Moonlight Gray Appearance | Uniform color with modern aesthetic | Meets architectural and project design requirements |

| Corrosion resistance | Resistant to rain, salt spray, and industrial pollutants | Suitable for coastal and high-humidity regions |

| Scratch & UV resistance | Maintains surface gloss over time | Extends product life, minimizes rework and replacement |

| Eco-friendly powder | Low VOC emissions, compliant with international standards | Meets export regulations, supports green construction projects |

Sunmay's durable aluminum coating excels not only in surface performance but also in practical usability across construction and industrial projects. By finely controlling powder particle uniformity and curing parameters, the coating achieves a high-quality moonlight gray aluminum finish that enhances aesthetic value. For procurement specialists and contractors, this reduces maintenance, lowers overall project costs, and ensures reliable supply across diverse climates in South America, Europe, and Africa. The environmentally friendly process aligns with international green building and export standards, allowing smooth project approval.

| Customer Pain Point | Solution |

|---|---|

| Coating prone to peeling or bubbling | High adhesion powder spraying and precise curing ensure a firm, smooth coating |

| Uneven or fading color | Uniform moonlight gray appearance with strong UV resistance maintains color stability |

| Corrosion in humid or coastal areas | Optimized corrosion-resistant formulation withstands salt spray and moisture |

| High maintenance costs | Durable coating reduces repair frequency and total ownership costs |

| Environmental regulation restrictions | Low-VOC coating meets export and environmental requirements for multiple markets |

Many aluminum profile buyers and contractors worry about coating durability and color consistency. Sunmay’s alloy powder coating addresses these issues with high adhesion and corrosion-resistant formulations while providing eco-friendly materials suitable for South American, European, and African export standards. This durable coating reduces maintenance, enhances project aesthetics, and ensures long-term value.

Sunmay’s durable aluminum coating finds versatile applications across various projects:

These scenarios demonstrate the coating’s ability to combine aesthetics with functionality, providing lasting value for clients in construction, industrial, and decorative applications.

Sunmay has a robust project management system and international export experience, capable of handling large-scale orders and cross-region deliveries. Each batch of durable aluminum coating is strictly monitored from raw material procurement, production, surface finishing, to packaging, ensuring compliance with international standards and client specifications. Logistics teams are experienced with South American, European, African, and North American transport requirements, supporting sea, air, and multimodal shipping to guarantee on-time delivery. Clients can enjoy customized labeling and packaging for bulk orders, streamlining the supply chain.

Q1: What is durable aluminum coating?

A1: Durable aluminum coating is a high-performance powder or liquid coating applied to aluminum profiles, providing corrosion, wear, and UV resistance to extend service life.

Q2: How does alloy powder coating differ from regular powder coating?

A2: Alloy powder coating uses specific aluminum alloy formulas and advanced curing processes, offering stronger adhesion, better corrosion resistance, and a high-quality moonlight gray aluminum finish.

Q3: What applications are suitable for moonlight gray aluminum finish?

A3: Ideal for architectural doors and windows, curtain walls, furniture, industrial equipment, and transportation facilities requiring aesthetic appeal, durability, and corrosion protection.

Q4: How to ensure durability in coastal areas?

A4: Optimized corrosion-resistant powder formulations, enhanced UV protection, and controlled coating thickness and curing processes ensure long-lasting performance.

Sunmay operates professional aluminum extrusion and surface finishing facilities equipped with multiple advanced powder coating production lines and automated spraying equipment. A comprehensive quality control system monitors raw materials, production processes, and finished products, ensuring each item meets international standards. The experienced team supports trade, construction, and engineering clients with reliable supply and technical expertise, maintaining a strong reputation in global markets.

Sunmay offers flexible customization services, including color matching, coating thickness adjustment, and special process treatments. Clients can request customized moonlight gray aluminum finish or other color options for bulk or small-batch orders. Technical teams provide professional guidance from sample creation to mass production, ensuring fast delivery and high-quality results. Successful project cases demonstrate Sunmay’s ability to respond efficiently to diverse client needs.

Sunmay’s OEM/ODM process includes the following stages: requirement communication, sample development and approval, production execution with strict quality control, customized packaging and logistics, and after-sales technical support. This streamlined process ensures clients receive professional service, clear communication, and reliable customized products efficiently, minimizing procurement risks.

Q1: How corrosion-resistant is alloy powder coating?

A1: Sunmay's alloy powder coating features optimized formulations and curing processes, offering excellent corrosion resistance against salt spray, high humidity, and industrial environments, ideal for coastal areas.

Q2: How long does the moonlight gray aluminum finish maintain its color?

A2: With high-quality powder and UV stabilizers, the coating maintains color for over 10 years in normal conditions, suitable for construction, furniture, and industrial applications.

Q3: Which industries are suitable for durable aluminum coating?

A3: Applicable in doors and windows, curtain walls, furniture, industrial equipment, transportation, and infrastructure projects, meeting high standards for aesthetics, durability, and environmental compliance.

Q4: How is batch consistency ensured?

A4: Fully automated spraying and curing lines, online inspection, and final product sampling ensure consistent coating thickness, color, and adhesion across batches.

Q5: Is customization available?

A5: Yes, Sunmay provides color customization, coating thickness adjustments, and special process treatments for both small and large orders.

Q6: How long does the OEM/ODM process take?

A6: From requirement communication and sample approval to mass production, the process typically takes 3–6 weeks and can be expedited if necessary.

Q7: Does the product meet environmental standards?

A7: Low-VOC powder coatings comply with international green building and export regulations, suitable for South America, Europe, and North America projects.

Q8: How is shipping and export managed?

A8: Sunmay has extensive export experience and supports sea, air, and multimodal transport with customized packaging to ensure safe delivery to clients.

Whatsapp : +8617366266559

Email : sales@sunmayalu.com

Tel : +86 -17366266559

Hi! Click one of our members below to chat on