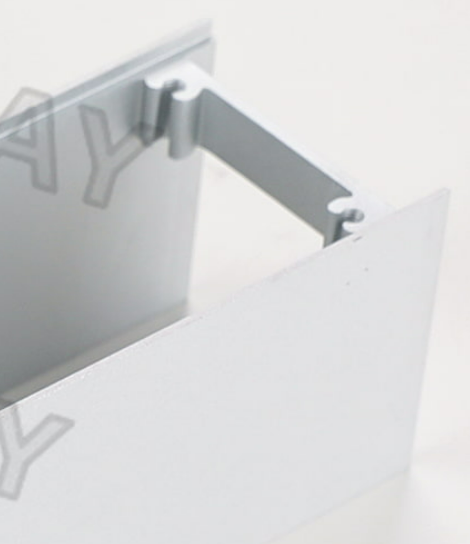

High-quality aluminum machining parts tailored for various industries. Ideal for construction, engineering, and manufacturing applications, offering durability and precision.

Material & Temper :

Custom Aluminum Alloy with Tempering ProcessLength :

By Custom LengthApplication :

Automotive, Electronics Industry, Construction IndustryLead time :

10 to 30 daysExecutable Quality Standard :

GB5237, TS16949, EN12020, EN755, EN573, Or according to customer agreement standardsSurface Treatment :

Anodizing/Powder Coating/Brushing/PaintingColor :

Silver, Champagne, Brown, Bronze, Black, GoldenPackaging method :

Customized according to customer requirementsWe specialize in manufacturing precision aluminum components for engineering, using advanced CNC machining technology to achieve high precision. Our manufacturing process ensures that every component meets the highest standards of accuracy. In addition to high precision, we offer a variety of surface treatments such as anodizing, electrocoating, and sandblasting to enhance the durability and appearance of the parts. Whether you need parts for mechanical equipment, automotive components, or electronic devices, our precision aluminum components will meet your exact requirements. In addition, we offer custom aluminum parts for industrial use. Our team works closely with clients to design and manufacture aluminum parts that meet their specific needs. From customized shapes and sizes to tailored surface finishes and colors, we provide flexible solutions that cater to your unique requirements. No matter the complexity, we can produce high-quality aluminum components that are perfect for any industrial application.

| Feature | Description |

|---|---|

| Material | High-strength aluminum alloy, offering lightweight and durable properties. |

| Surface Treatment | Anodizing, electrocoating, and sandblasting to enhance corrosion resistance and durability. |

| Precision | CNC machining ensures high accuracy and precision for each part. |

| Customization | Custom design, size, color, and surface finish available to meet your exact requirements. |

| Hardness | Adjustable hardness to meet different engineering standards. |

| Tensile Strength | High tensile strength suitable for heavy-duty applications. |

Summary: Our aluminum machining parts are crafted using the highest quality aluminum alloys and precision CNC machining to ensure they are both durable and reliable. With flexible customization options and a range of surface treatments, we provide solutions that meet the needs of the construction, engineering, and industrial sectors.

| Customer Need | Solution |

|---|---|

| High precision and durability | We use CNC machining technology to ensure each part is precisely manufactured according to engineering requirements. |

| Corrosion resistance and oxidation prevention | We offer anodizing and electrocoating surface treatments to enhance the corrosion resistance of the parts. |

| Customization requirements | We provide full customization services to meet your specifications for size, shape, surface treatment, and color. |

| Fast delivery | We have a robust production capability and can meet tight delivery schedules, ensuring on-time delivery for your projects. |

Aluminum machining parts for construction are widely used in the construction industry due to their excellent properties such as high strength, corrosion resistance, and lightweight. Our aluminum machining parts are made from high-quality aluminum alloys, ensuring they meet the rigorous demands of modern construction projects. Whether it's for structural applications, installations, or repairs, these parts provide a perfect solution where durability and reliability are essential.

Construction Industry: Our aluminum machining parts are widely used in the construction sector, particularly for applications such as window frames, exterior facades, ceiling systems, and partition walls. Due to the lightweight and corrosion-resistant properties of aluminum, these parts perform well in harsh environments, such as high temperatures, humidity, and coastal areas, ensuring long-term stability and performance.

Engineering and Manufacturing Industries: Precision aluminum components play a crucial role in various engineering and industrial applications, including machinery, automotive components, and electronics. Our custom aluminum parts are designed to meet specific requirements, offering exceptional strength and durability for mechanical and industrial use.

As a leading manufacturer of aluminum machining parts, we have the ability to supply products for large-scale projects. We offer flexible shipping options and can accommodate mixed-container shipments to various ports, ensuring smooth and timely delivery of your orders. Our global logistics system allows us to efficiently ship products to destinations worldwide, ensuring the best service and delivery times for our customers. We support multiple ports for delivery, offering diverse options to optimize your shipping process. Whether you need a single product or a mixed shipment, we are capable of fulfilling large orders and meeting tight deadlines. Our delivery flexibility ensures that you receive the products you need, when you need them.

Sunmay is a trusted brand with 20 years of experience in manufacturing aluminum products. We specialize in providing high-quality aluminum machining parts for construction, engineering, and industrial applications. Our factory is certified with CE, RoHS, and REACH certifications, ensuring that our products meet international standards. We are committed to delivering high-quality solutions that exceed customer expectations. With a reputation for excellence and innovation, Sunmay has built strong relationships with clients worldwide, providing them with reliable aluminum solutions that enhance their operations. Our dedication to quality and customer satisfaction sets us apart in the industry.

Q1: Can I customize aluminum machining parts based on my specific requirements?

A1: Yes, we offer full customization services for size, shape, surface finish, and color. Our team works closely with clients to ensure the parts meet their exact specifications.

Q2: What is the minimum order quantity?

A2: Our minimum order quantity is 2 tons, but we are happy to discuss specific order volumes based on your needs.

Q3: What shipping options do you provide?

A3: We offer mixed-container shipments and can deliver to multiple ports worldwide, providing flexibility to meet your needs.

Q4: Do your products meet international quality standards?

A4: Yes, our products are certified with CE, RoHS, and REACH, ensuring they meet international quality standards.

Tags :

Whatsapp : +8617366266559

Email : sales@sunmayalu.com

Tel : +86 -17366266559

Hi! Click one of our members below to chat on